Supporting equipment for bridge engineering construction

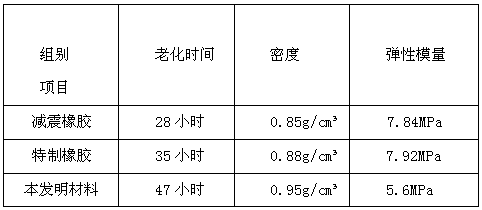

A technology for supporting equipment and bridge engineering, used in bridge construction, bridges, erection/assembly of bridges, etc., can solve the problems of anti-aging, poor elasticity, and inconvenient installation of shock-absorbing materials, and achieve high overall structural strength. The effect of long life and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

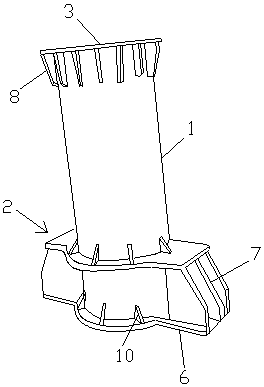

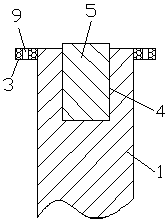

[0022] Such as figure 1 and figure 2 Shown, a kind of support equipment for bridge engineering construction, comprises cylinder 1, base 2 and retaining ring 3, described cylinder 1 is welded on the base 2, and described retaining ring 3 is welded on the top of cylinder 1, so A groove 4 is provided above the middle part of the column body 1, and a shock-absorbing column 5 is arranged in the groove 4. The base 2 includes two bottom plates 6 arranged in parallel, and the inner side of the middle part of the bottom plate 6 is circular. Holes are set, and the middle part of the bottom plate 6 is arranged as an arc-shaped protrusion on the outer side of the middle part. A plurality of partitions 7 are welded between the bottom plate 6, and the bottom of the retaining ring 3 and the outer side of the cylinder 1 are welded in an annular array. A reinforcing rib 8 .

[0023] The surface of the retaining ring 3 is provided with through holes 9 in an annular array.

[0024] The top o...

Embodiment 2

[0034] Such as figure 1 and figure 2 Shown, a kind of support equipment for bridge engineering construction, comprises cylinder 1, base 2 and retaining ring 3, described cylinder 1 is welded on the base 2, and described retaining ring 3 is welded on the top of cylinder 1, so A groove 4 is provided above the middle part of the column body 1, and a shock-absorbing column 5 is arranged in the groove 4. The base 2 includes two bottom plates 6 arranged in parallel, and the inner side of the middle part of the bottom plate 6 is circular. Holes are set, and the middle part of the bottom plate 6 is arranged as an arc-shaped protrusion on the outer side of the middle part. A plurality of partitions 7 are welded between the bottom plate 6, and the bottom of the retaining ring 3 and the outer side of the cylinder 1 are welded in an annular array. A reinforcing rib 8 .

[0035] The surface of the retaining ring 3 is provided with through holes 9 in an annular array.

[0036] The top o...

Embodiment 3

[0046] Such as figure 1 and figure 2 Shown, a kind of support equipment for bridge engineering construction, comprises cylinder 1, base 2 and retaining ring 3, described cylinder 1 is welded on the base 2, and described retaining ring 3 is welded on the top of cylinder 1, so A groove 4 is provided above the middle part of the column body 1, and a shock-absorbing column 5 is arranged in the groove 4. The base 2 includes two bottom plates 6 arranged in parallel, and the inner side of the middle part of the bottom plate 6 is circular. Holes are set, and the middle part of the bottom plate 6 is arranged as an arc-shaped protrusion on the outer side of the middle part. A plurality of partitions 7 are welded between the bottom plate 6, and the bottom of the retaining ring 3 and the outer side of the cylinder 1 are welded in an annular array. A reinforcing rib 8 .

[0047] The surface of the retaining ring 3 is provided with through holes 9 in an annular array.

[0048] The top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com