Cooling fan material of automobile engine and preparation method thereof

A technology of automobile engine and cooling fan, which is applied in the direction of engine cooling, engine components, machine/engine, etc. It can solve problems such as non-aging, engine overheating, pipe rupture, etc., and achieve good flame retardant effect, high structural strength, and maintenance The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

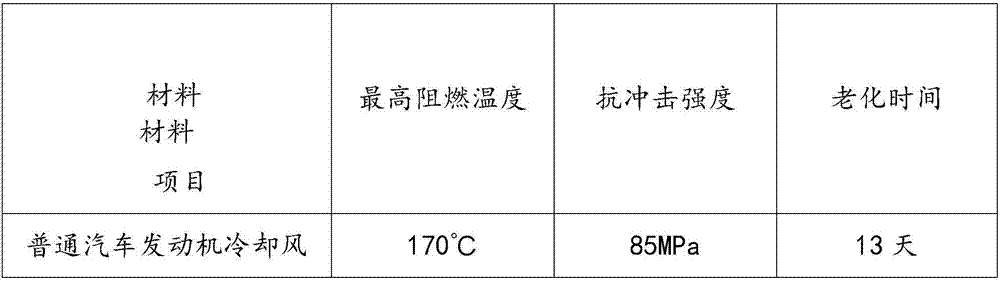

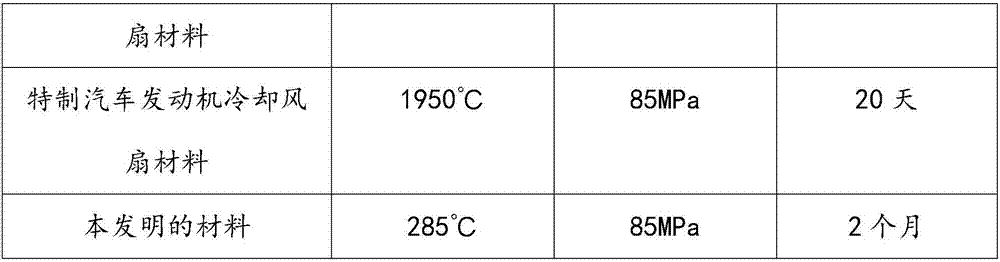

Examples

Embodiment 1

[0019] A cooling fan material for an automobile engine, made of the following materials in parts by weight, including 17 parts of o-methylbenzene glycol, 16 parts of polyacrylamide, 8 parts of silicon dioxide, 9 parts of polyphenylene ester, and polyarylether 18 parts of ketone, 20 parts of polybutylene terephthalate, 8 parts of polyphenylene ether, 7 parts of sodium alkylsulfonate, 3 parts of ethoxylated lauramide, 5 parts of fatty amine polyoxyethylene ether, organic quaternary 6 parts of ammonium salt, 22 parts of glass fiber, 13 parts of dimethyl sebacate, 5 parts of benzotriazole, 10 parts of nano titanium dioxide, 22 parts of polyvinyl butyral and 6 parts of ammonium dihydrogen phosphate.

[0020] A preparation method for an automobile engine cooling fan material, comprising the following steps:

[0021] 1) 17 parts of o-methylbenzene glycol, 16 parts of polyacrylamide, 8 parts of silicon dioxide, 9 parts of polyphenylene, 18 parts of polyaryletherketone, 20 parts of pol...

Embodiment 2

[0028] A cooling fan material for an automobile engine, made of the following materials in parts by weight, including 21.5 parts of o-methylbenzene glycol, 18 parts of polyacrylamide, 11 parts of silicon dioxide, 12.5 parts of polyphenylene, polyarylamide 18.5 parts of ether ketone, 22 parts of polybutylene terephthalate, 9.5 parts of polyphenylene ether, 12.5 parts of sodium alkylsulfonate, 4.5 parts of ethoxylated lauramide, 8 parts of fatty amine polyoxyethylene ether, organic 6.5 parts of quaternary ammonium salt, 24 parts of glass fiber, 14.5 parts of dimethyl sebacate, 7 parts of benzotriazole, 12.5 parts of nano titanium dioxide, 24 parts of polyvinyl butyral and 6.5 parts of ammonium dihydrogen phosphate.

[0029] A preparation method for an automobile engine cooling fan material, comprising the following steps:

[0030] 1) 21.5 parts of o-methylbenzene glycol, 18 parts of polyacrylamide, 11 parts of silicon dioxide, 12.5 parts of polyphenylene ester, 18.5 parts of pol...

Embodiment 3

[0037]A cooling fan material for an automobile engine, made of the following materials in parts by weight, including 25 parts of o-methylbenzene glycol, 20 parts of polyacrylamide, 14 parts of silicon dioxide, 16 parts of polyphenylene, polyarylamide 19 parts of ether ketone, 24 parts of polybutylene terephthalate, 11 parts of polyphenylene ether, 18 parts of sodium alkylsulfonate, 6 parts of ethoxy lauramide, 11 parts of fatty amine polyoxyethylene ether, organic 7 parts of quaternary ammonium salt, 26 parts of glass fiber, 16 parts of dimethyl sebacate, 9 parts of benzotriazole, 15 parts of nano titanium dioxide, 26 parts of polyvinyl butyral and 7 parts of ammonium dihydrogen phosphate.

[0038] A preparation method for an automobile engine cooling fan material, comprising the following steps:

[0039] 1) 25 parts of o-methylbenzene glycol, 20 parts of polyacrylamide, 14 parts of silicon dioxide, 16 parts of polyphenylene ester, 19 parts of polyaryletherketone, 24 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com