Fireproof layer and fireproof wooden door

A fireproof layer and wooden door technology, which is applied to fireproof doors, door leaves, windows/doors, etc., can solve the problems of large fireproof layer thickness, large overall thickness of wooden doors, troublesome use, etc., and achieve the effect of reduced thickness and good fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

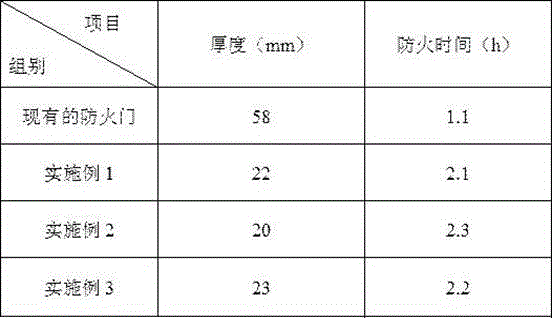

[0027] The fireproof layer 2 is composed of 16 parts of aluminum oxide, 12 parts of kyanite powder, 7 parts of polyurethane, 16 parts of asbestos cellulose, 18 parts of sepiolite, 8 parts of ammonium metavanadate, tetrafluoride 3 parts of zirconium, 8 parts of cyclohexanol, 6 parts of propolis, 10 parts of titanium carbide, 8 parts of zirconium diboride, 16 parts of sandstone powder, 6 parts of hydroquinone, 3 parts of sodium borohydride and 6 parts of ammonium molybdate production.

[0028] The fireproof layer 2 can be made to have a thickness of 12mm to meet the requirement of 2 hours fireproof time. The 48mm thickness of the traditional fireproof layer only meets the requirement of 1 hour fireproof time.

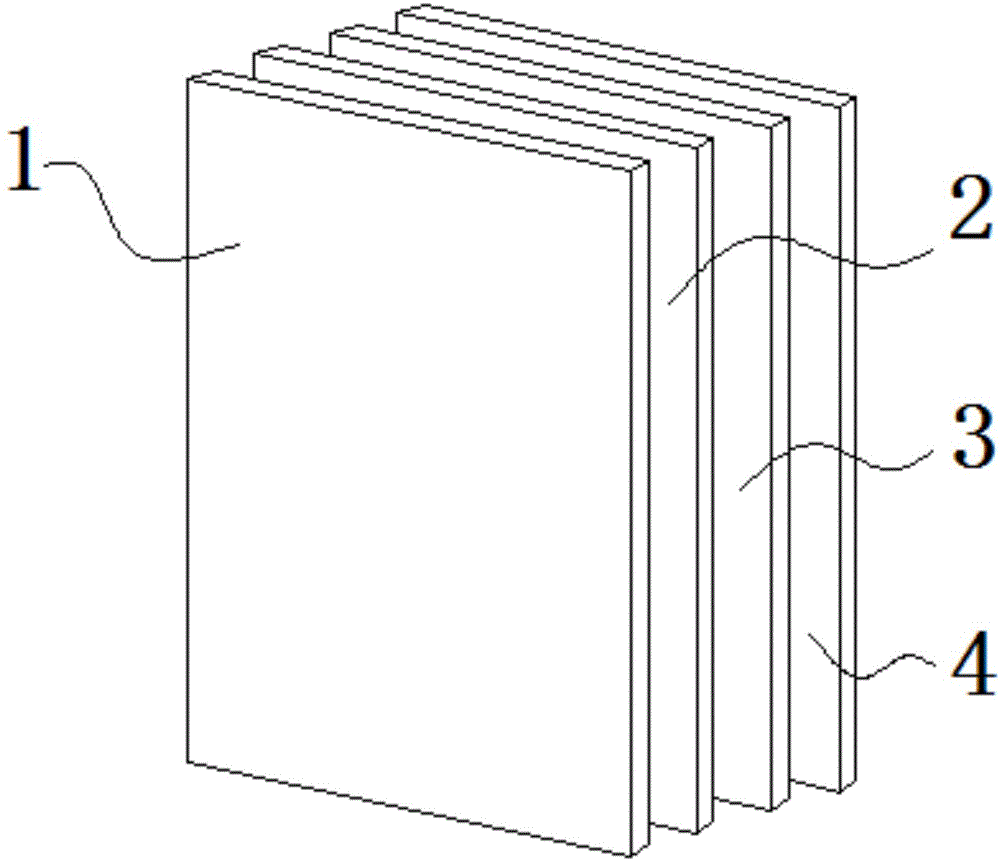

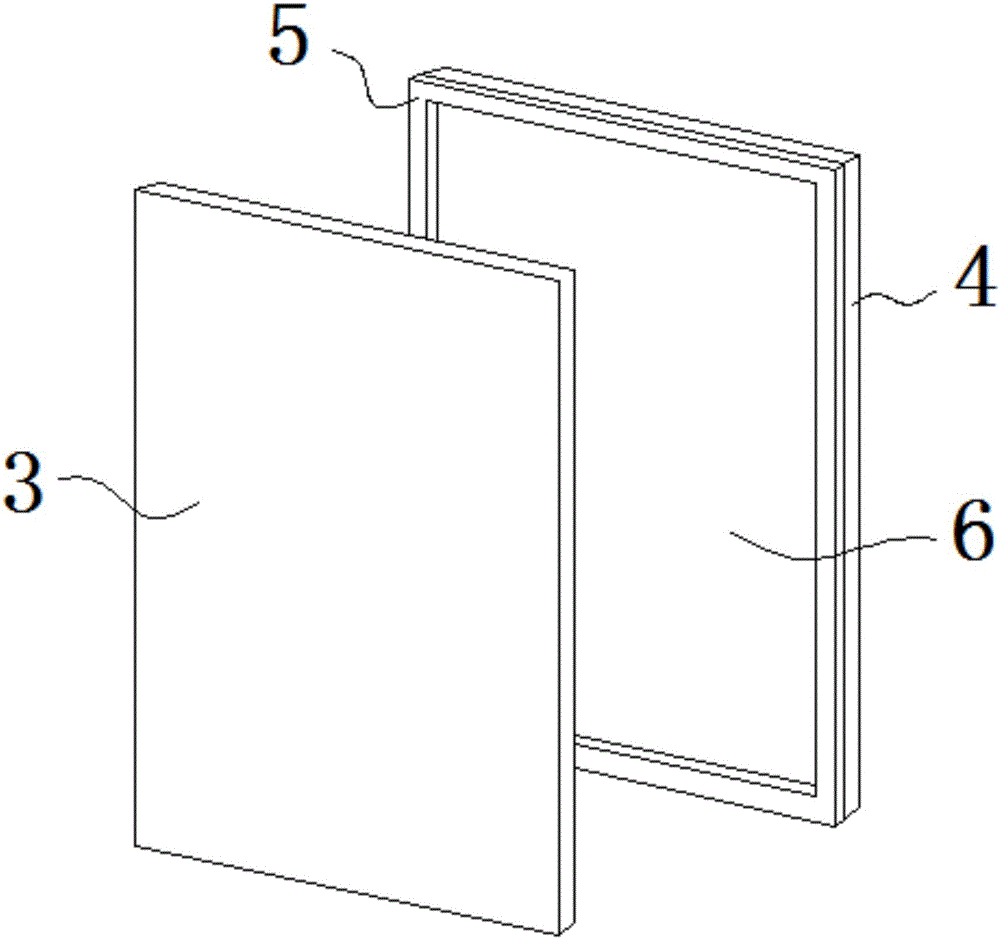

[0029] like figure 1 As shown, a fireproof wooden door includes a panel 1; and the above-mentioned fireproof layer 2, which is fixedly connected to the panel 1.

[0030] The above fireproof wooden door also includes a door core 3 and a backboard 4, and the panel 1, the...

Embodiment 2

[0043] The fireproof layer 2 is composed of 14 parts of aluminum oxide, 11 parts of kyanite powder, 6 parts of polyurethane, 17 parts of asbestos cellulose, 19 parts of sepiolite, 9 parts of ammonium metavanadate, tetrafluoride 4 parts of zirconium, 10 parts of cyclohexanol, 8 parts of propolis, 11 parts of titanium carbide, 10 parts of zirconium diboride, 17 parts of sandstone powder, 7 parts of hydroquinone, 4 parts of sodium borohydride and 8 parts of ammonium molybdate production.

[0044] The fireproof layer 2 can be made to have a thickness of 12mm to meet the requirement of 2 hours fireproof time. The 48mm thickness of the traditional fireproof layer only meets the requirement of 1 hour fireproof time.

[0045] like figure 1 As shown, a fireproof wooden door includes a panel 1; and the above-mentioned fireproof layer 2, which is fixedly connected to the panel 1.

[0046] The above fireproof wooden door also includes a door core 3 and a backboard 4, and the panel 1, t...

Embodiment 3

[0059] The fireproof layer 2 is composed of 12 parts of aluminum oxide, 10 parts of kyanite powder, 5 parts of polyurethane, 18 parts of asbestos cellulose, 20 parts of sepiolite, 10 parts of ammonium metavanadate, tetrafluoride 5 parts zirconium, 12 parts cyclohexanol, 10 parts propolis, 12 parts titanium carbide, 12 parts zirconium diboride, 18 parts sandstone powder, 8 parts hydroquinone, 5 parts sodium borohydride and 10 parts ammonium molybdate production.

[0060] The fireproof layer 2 can be made to have a thickness of 12mm to meet the requirement of 2 hours fireproof time. The 48mm thickness of the traditional fireproof layer only meets the requirement of 1 hour fireproof time.

[0061] Such as figure 1 As shown, a fireproof wooden door includes a panel 1; and the above-mentioned fireproof layer 2, which is fixedly connected to the panel 1.

[0062] The above fireproof wooden door also includes a door core 3 and a backboard 4, and the panel 1, the fireproof layer 2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com