Flexible ceramic coating and preparation method thereof

A technology of flexible ceramics and coatings, which is applied in the field of coatings, can solve the problems that large bending deformation cannot occur, restrict the popularization and application of ceramic coatings, and the coatings do not have recoatability, so as to achieve long pot life, improve recoating performance, The effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

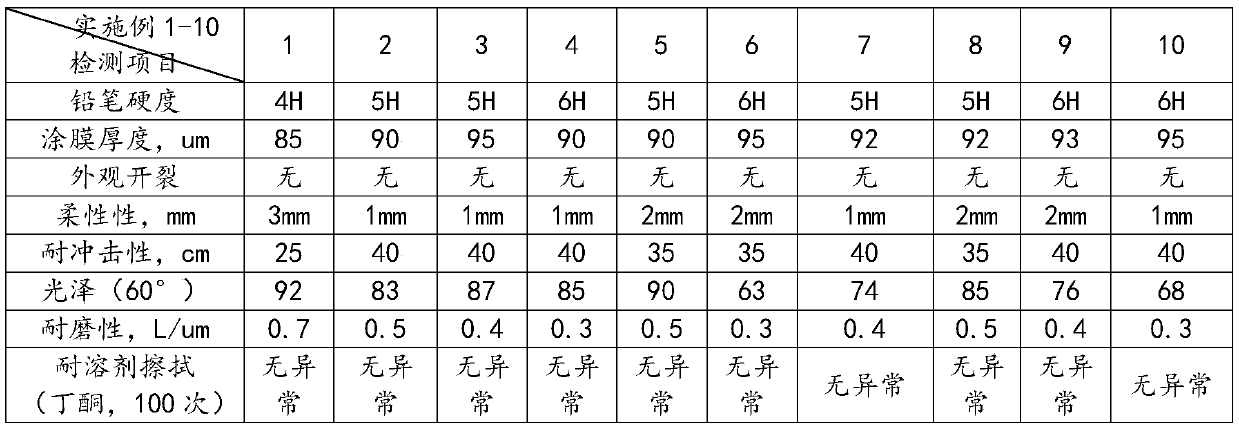

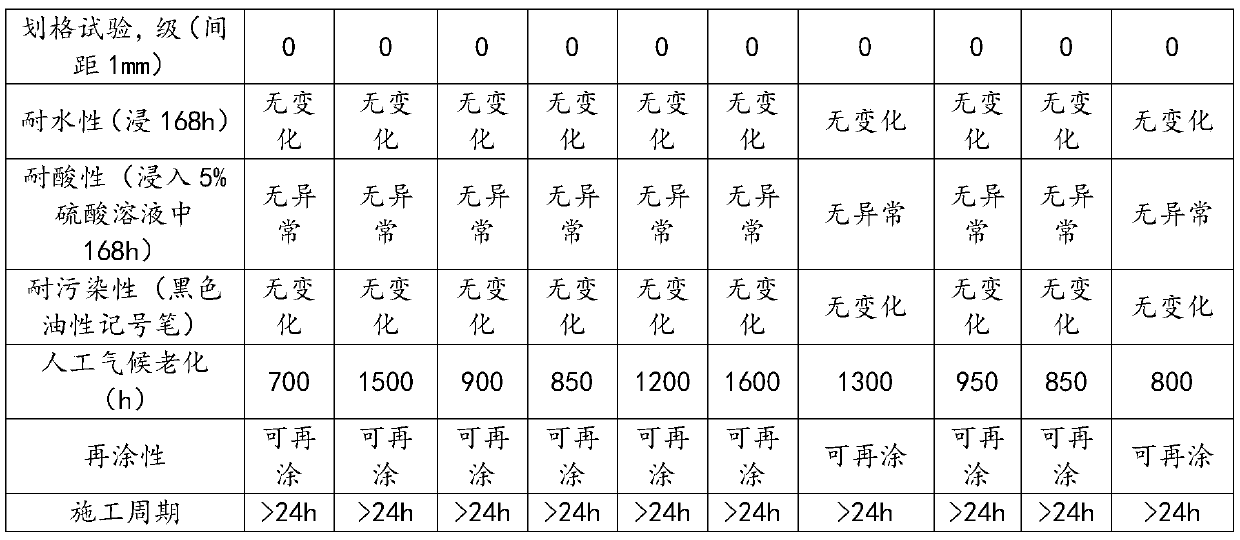

Examples

Embodiment 1

[0037] The flexible ceramic coating of this embodiment is prepared by mixing component A, component B, and component C. The component A is mainly composed of the following components in parts by mass: acid silicon with a silicon dioxide content of 40%. Sol 99 parts, defoamer Airex 901W 0.2 parts, wetting and leveling agent BYK-333 0.8 parts; the B component is mainly composed of the following components in mass parts: 10 parts of methyl orthosilicate, methyl trimethyl 50 parts of oxysilane, 5 parts of phenyltrimethoxysilane, 10 parts of dimethyldimethoxysilane, 15 parts of γ-glycidyl etheroxypropyl trimethoxysilane, 2 parts of tetra-n-butyl titanate, 8 parts of ethanol; the C component is a silicone-modified acrylic emulsion; the mass ratio of the A component, B component, and C component is 25:10:4.

[0038] The organosilicon-modified acrylic emulsion of the present embodiment is mainly made of the following raw materials in mass percentage:

[0039] Methyl Methacrylate 18%,...

Embodiment 2

[0050] The flexible ceramic coating of this embodiment is prepared by mixing component A, component B, and component C. The component A is mainly composed of the following components in parts by mass: acid silicon with a silicon dioxide content of 30%. Sol 20 parts, pigment titanium dioxide 35 parts, filler precipitated barium sulfate 5 parts, filler talc powder 5 parts, dispersant BYK-190 5 parts, defoamer Airex 901W 0.5 parts, wetting and leveling agent BYK-333 1.5 parts, 0.5 parts of anti-sedimentation additive BENTONE LT, 27.5 parts of deionized water; the B component is mainly composed of the following components in mass parts: 10 parts of ethyl orthosilicate, 55 parts of methyltrimethoxysilane, dimethyl 5 parts of dimethoxysilane, 5 parts of diphenyldimethoxysilane, 10 parts of chloropropyltrimethoxysilane, 5 parts of γ-(methacryloxy)propyltrimethoxysilane, titanic acid 3 parts of tetra-n-butyl ester, 7 parts of ethanol; the C component is a silicone-modified acrylic emu...

Embodiment 3

[0063] The flexible ceramic coating of this embodiment is prepared by mixing component A, component B, and component C. The component A is mainly composed of the following components in parts by mass: acid silicon with a silicon dioxide content of 30%. 30 parts of colloidal sol, 10 parts of acidic silica sol with a silica content of 40%, 15 parts of pigment iron yellow, 5 parts of filler alumina, 5 parts of filler talc powder, 5 parts of filler mica powder, 7 parts of filler whisker silicon, disperse AFCONA 4530 6 parts, defoamer Airex 901W 0.5 parts, wetting and leveling agent BYK-333 1.0 parts, anti-sedimentation additive BENTONE LT 0.5 parts, deionized water 15 parts; the B component mainly consists of the following parts by mass Number of components: 69 parts of methyltrimethoxysilane, 8 parts of phenyltrimethoxysilane, 10 parts of γ-(methacryloyloxy)propyltrimethoxysilane, 4 parts of tetra-n-butyl titanate , 9 parts of ethanol; the C component is a silicone-modified acryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com