Preparation method for low free toluene diisocyanate (TDI) polyurethane pre-polymer curing agent

A polyurethane prepolymer and low-free technology, applied in coatings and other directions, can solve the problems of prepolymers having no practical value, endangering the physical and mental health of builders, and lack of elasticity, and achieve low toxicity of products, increased construction time limit, and low color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

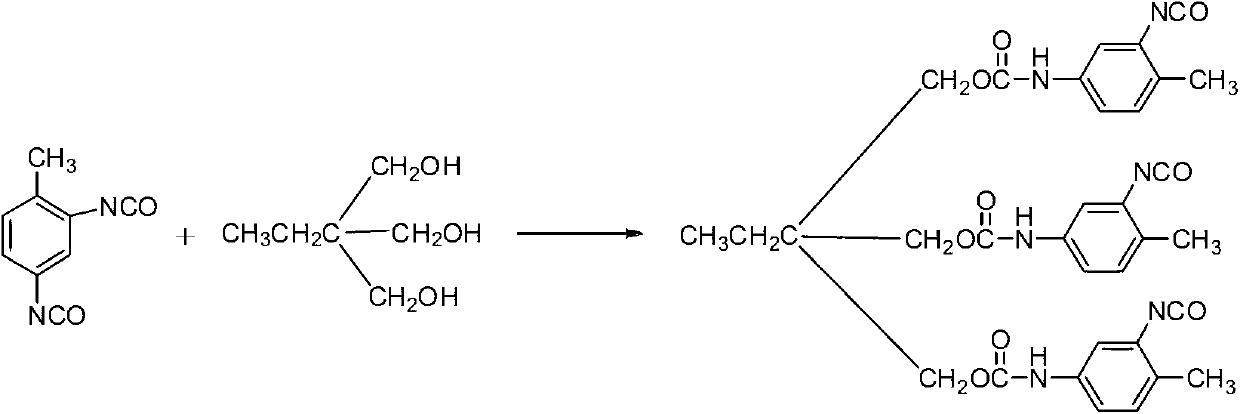

Method used

Image

Examples

Embodiment 1

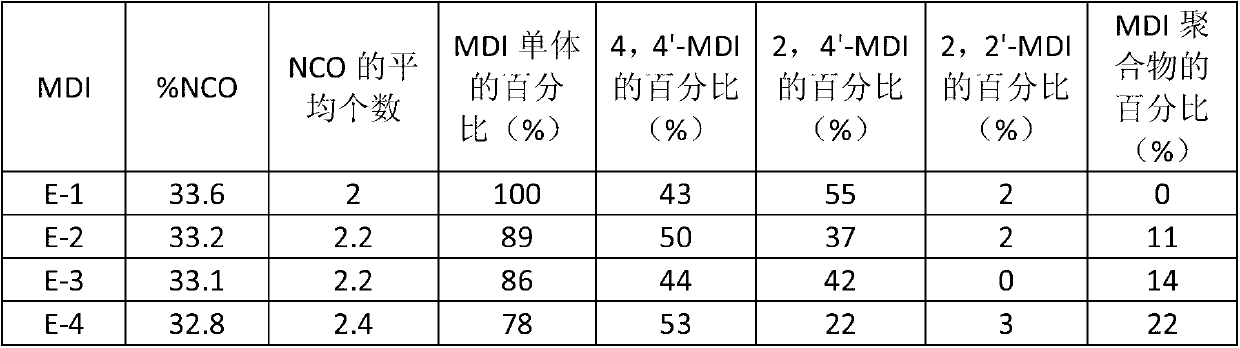

[0032] In a four-neck flask equipped with a thermometer, an electromagnetic stirrer, and a reflux condenser, under the protection of nitrogen, add 45g of TDI (A-1) and 474.94g of dehydrated butyl acetate (component B), keep warm in a water bath at 40°C, and stir for 10min , so that it is mixed uniformly to obtain a TDI solution. Heat and melt 11.55 g of dehydrated trihydroxypropane (TMP, component C), and keep it in a liquid state using a heat preservation device. Then, TMP was added dropwise to the TDI solution, and the drop was completed in half an hour. Insulated for two hours, NCO was 19.10% (detecting the weight percentage of NCO groups, NCO groups accounted for the total solids mass percentage, that is, removing other components except the solvent, and the detection method of the following embodiments is the same), The obtained TDI / TMP prepolymer (see Table 2). Add 300g of MDI (E-1) to the TDI / TMP prepolymer, mix thoroughly for half an hour, and the NCO is 31.01%, to o...

Embodiment 2

[0034] In a four-necked flask equipped with a thermometer, an electromagnetic stirrer, and a reflux condenser, under the protection of nitrogen, add 45g of TDI (A-1) and 490.93g of dehydrated butyl acetate, keep the temperature in a water bath at 40°C, and stir for 10 minutes to make it evenly mixed , to obtain TDI solution. Heat and melt 11.55g of dehydrated trihydroxypropane, and keep it in a liquid state by using a heat preservation device to keep it warm. Then, TMP was added dropwise to the TDI solution, and the drop was completed in half an hour. After incubation for two hours, the NCO was 19.10%, and the obtained TDI / TMP prepolymer was obtained (see Table 2). Add 300g of MDI (E-1), and mix well under electromagnetic stirring for half an hour, and the NCO is 31.01%. Add 134.38 g of n-pentanol dropwise into the mixture of TDI / TMP / MDI, and keep the temperature at 60° C. for 3 hours. Cool down, stop and discharge. Finally, a clear product with an NCO content of 9.81%, a ...

Embodiment 3

[0036]In a four-neck flask equipped with a thermometer, an electromagnetic stirrer, and a reflux condenser, under the protection of nitrogen, add 45g of TDI (A-1), 619.39g of a 1:1 mixture of dehydrated butyl acetate and ethyl acetate, and keep the water bath for 40 ℃, stirring for 10 min to make it evenly mixed. Heat and melt 11.55g of dehydrated trihydroxypropane, and keep it in a liquid state by using a heat preservation device to keep it warm. Then, TMP was added dropwise to the TDI solution, and the drop was completed in half an hour. After incubation for two hours, the NCO was 19.10%, and the obtained TDI / TMP prepolymer was obtained (see Table 2). Add 350g of MDI (E-2), and mix thoroughly for half an hour under electromagnetic stirring, and the NCO is 31.07%. 212.84 g of n-octanol was added dropwise into the mixture of TDI / TMP / MDI, and the temperature was kept at 60° C. for 3 hours. Cool down, stop and discharge. The finally obtained NCO content is 9.53%, the viscosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com