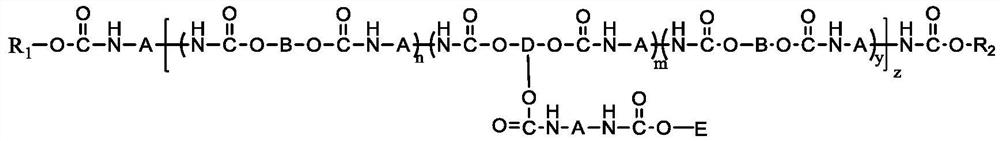

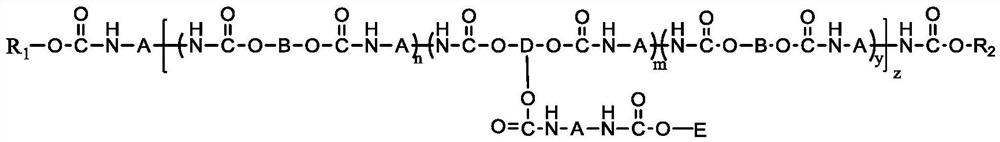

Polyurethane thickening agent with dispersing function as well as preparation method and application thereof

A polyurethane and thickener technology, applied in dyeing, textiles, papermaking, coating, etc., to achieve good matching and compatibility, dense three-dimensional network structure, and reduce the effect of small molecular hydrophilic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Prepare polyurethane thickener C1 with dispersing function, its synthetic formula is composed as follows:

[0076] Table 1

[0077]

[0078] The steps of the polyurethane thickener with dispersion function synthesized by this formula are as follows:

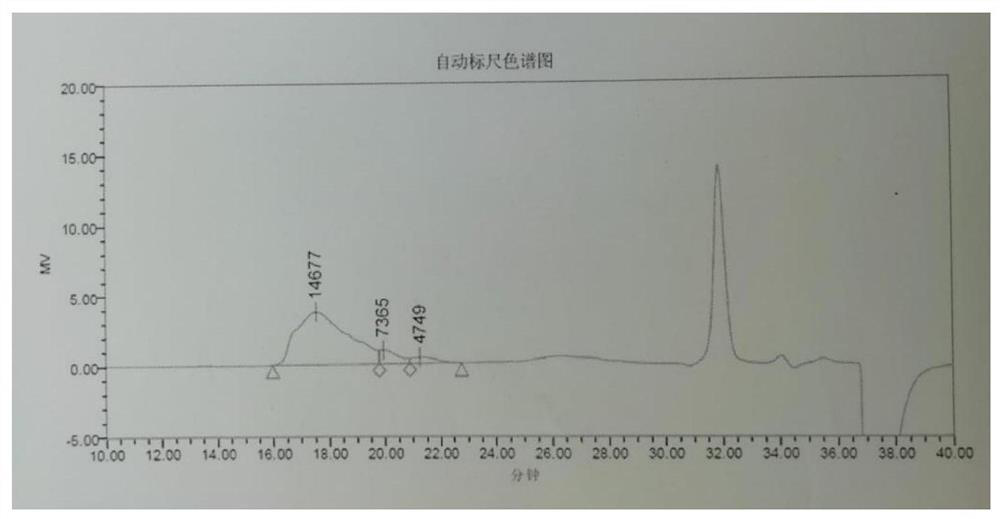

[0079] 1) Under a nitrogen atmosphere, add 53.4g of butyl acetate into a 500ml flask, start stirring and heat up to 90°C, weigh 20g of butyl acetate, 1.8g of polyethylene glycol acrylic acid-11, and 11.78g of Acrylic acid, 35.35g styrene, 0.098g BPO and 0.15g dodecyl mercaptan were mixed evenly, and the liquid in the dropping bottle was added dropwise to the flask for polymerization reaction in 2 hours. Reaction obtains polyacrylate polymer (tested by GPC, its mass-average molecular weight is 14677) and its GPC spectrogram of polyacrylate polymer is as follows figure 1 as shown.;

[0080] 2) Add 100g of polyethylene glycol 6000 (PEG6000) into a 500ml three-neck flask equipped with electromagnetic stirring and nitrog...

Embodiment 2

[0088] Prepare polyurethane thickener C2 with dispersing function, its synthetic formula is composed as follows:

[0089] Table 2

[0090]

[0091] The synthesis steps of Example 2 are the same as those of Example 1, and will not be repeated here. The obtained polyacrylate polymer passed the GPC test, and its mass-average molecular weight was 17762. According to this formula, the polyurethane thickener C2 with dispersing function was obtained.

[0092]

[0093] Wherein, n=4, m=1, y=1, z=2.

Embodiment 3

[0095] Prepare polyurethane thickener C3 with dispersing function, and its synthetic formula is composed as follows:

[0096] table 3

[0097]

[0098]

[0099] The synthesis steps of Example 3 are the same as those of Example 1, and will not be repeated here. The obtained polyacrylate polymer passed the GPC test, and its mass-average molecular weight was 15478. According to this formula, the polyurethane thickener C3 with dispersing function was obtained.

[0100]

[0101] Wherein, n=2, m=2, y=3, z=1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com