Internal combustion engine oil composite tackifier and preparation method thereof

A composite thickener, internal combustion engine oil technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of poor shear resistance, poor low temperature performance, low thickening efficiency, etc., to achieve excellent oxidation resistance, Improved oil film and high thickening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

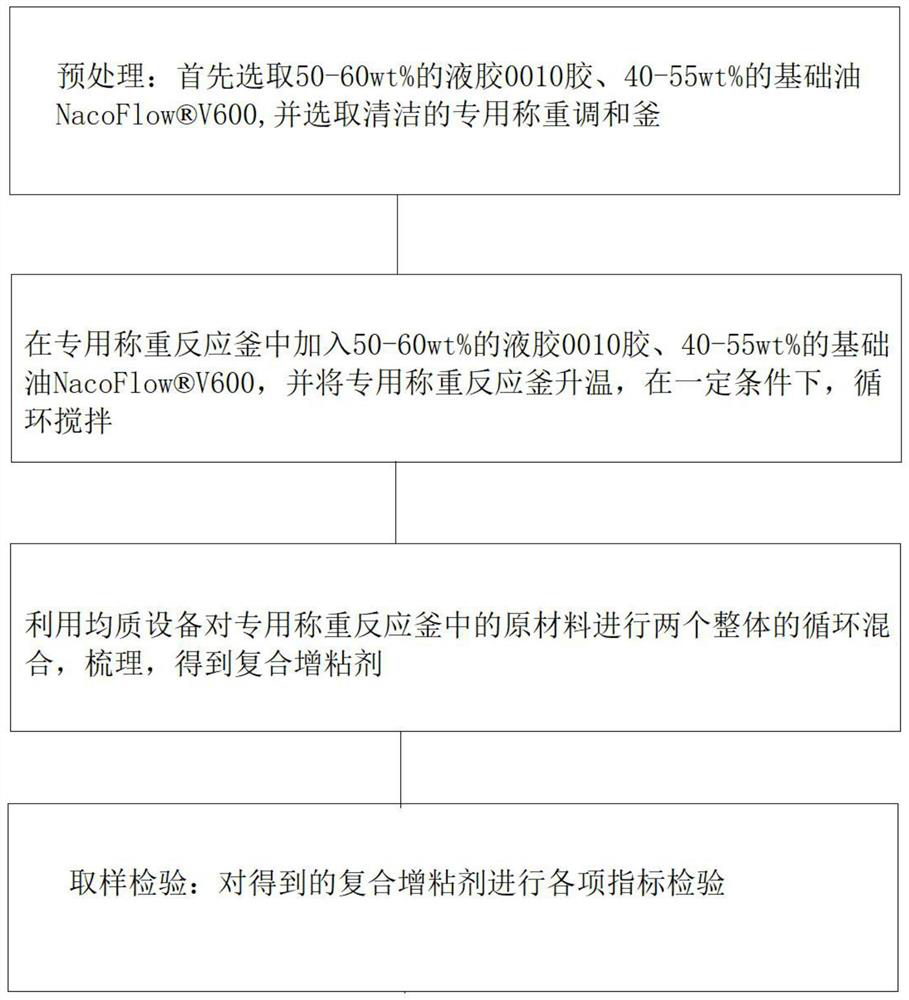

[0023] (1) Pretreatment: first select 50wt% liquid glue 0010 glue, 50wt% base oil And select a clean special weighing and blending kettle;

[0024] (2) Add 50wt% liquid glue 0010 glue and 50wt% base oil in the special weighing reaction kettle And raise the temperature of the special weighing reaction kettle to 120°C, keep the temperature constant, and circulate and stir under the protection of nitrogen;

[0025] (3) Utilize homogeneous equipment to carry out two overall circulation mixings to the raw material in the special-purpose weighing reactor, comb, obtain composite tackifier;

[0026] (4) Sampling inspection: carry out various index inspections on the obtained composite tackifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com