Polyurethane and preparation method and application thereof

A polyurethane and preparation technology, which is applied in the field of water-soluble or water-dispersed polyurethane, can solve the problems such as the performance characteristics of polyurethane thickeners that are not mentioned, and achieve good storage stability, good system compatibility, and high thickening efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Add 50g of polyethylene glycol 8000 (PEG8000) into a 250ml three-neck flask equipped with electromagnetic stirring and nitrogen inlet, and remove water at 110°C for 1.5 hours under negative pressure (pressure less than 100Pa). The temperature was lowered to 90°C, and mechanical stirring was used instead. Under the protection of nitrogen, 0.04g of catalyst BICAT8018 (American Leading Chemicals), 1.31g of HDI was added, and reacted at 90°C for 1h, then 0.67g of HMA was added, and reacted at 90°C for 2h to obtain polyurethane.

[0061] After completion of the reaction, add 207.92g of water to the prepared polyurethane to form a 20% solid aqueous solution to obtain a polyurethane thickener preparation (Thickener 1) with a viscosity of 3.5Pa.s (Browler Fei CAP2000+ cone-plate viscometer) .

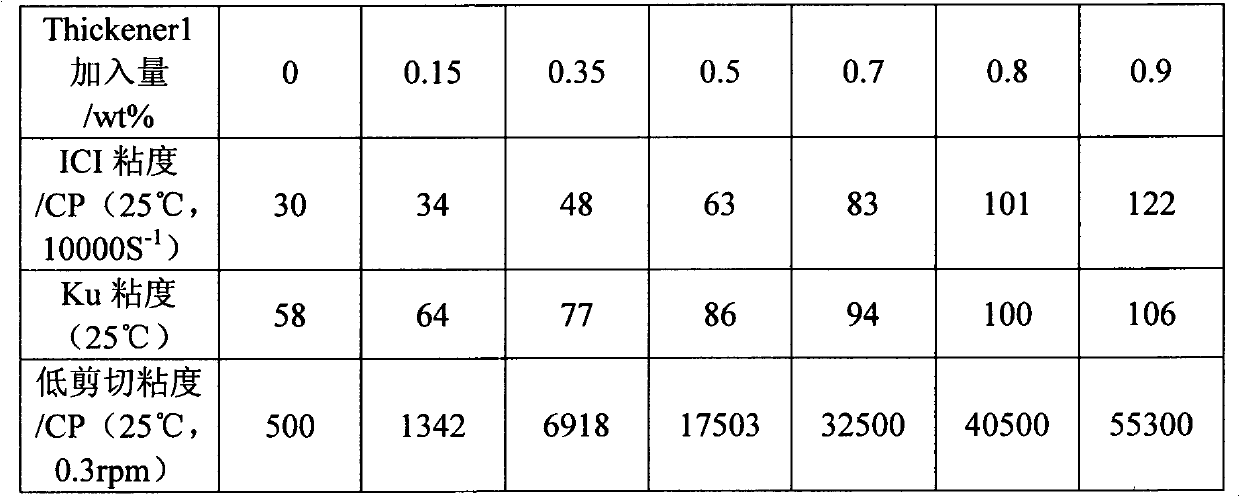

[0062] The above polyurethane thickener formulation was used in 300 g of acrylic emulsion (DOW Chemical Primal TM -AC261 emulsion) thickening, wherein, the Thickener 1 addition accounts...

Embodiment 2

[0067] Similar to the implementation method of Case 1, but using 2.04g HMDI instead of the 1.31g HDI used in Example 1.

[0068] After the reaction is complete, use 210.84g of water containing 26.38g of nonionic surfactant ANTAROX BL-225 (Rhodia Company) instead of 207.92g of water to make a 20% solid solution to obtain a polyurethane thickener preparation (Thickener 2) , The viscosity is 5Pa.s.

[0069] The same method as in Example 1 was used to measure the thickening performance of the thickener preparation on the emulsion. Among them, the addition of Thickener2 accounted for 0%, 0.04%, 0.08%, 0.12%, 0.16%, 0.2%, and 0.24% of the weight of the acrylic emulsion respectively. The test results are shown in Table 2.

[0070] Table 2 Example 2 Experimental Results

[0071]

[0072] It can be seen from Table 2 that the polyurethane thickener in Example 2 has extremely high thickening efficiency, and can effectively increase the medium and low shear viscosity of the emulsion ...

Embodiment 3

[0074] Similar to the implementation method of case 1, what adopted was 1.77g IPDI instead of 1.31g HDI to synthesize polyurethane. After the reaction was completed, 209.76g water was used to make a 20% solid solution to obtain a polyurethane thickener preparation (Thickener 3), with a viscosity of 4.5Pa.s.

[0075] The same method as in Example 1 was used to measure the thickening performance of the thickener on the emulsion, wherein the amount of Thickener 3 added was the same as in Example 1, and the test results are shown in Table 3.

[0076] Table 3 Example 3 Experimental Results

[0077]

[0078] It can be seen from Table 3 that the polyurethane thickener in Example 3 has better thickening efficiency, can increase the high, medium and low shear viscosity of the emulsion at the same time, and has a relatively balanced performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com