Preparation method of two-in-one emulsion for multicolor paint

A multi-color, two-in-one technology, used in multi-color effect coatings, coatings, etc., can solve the problems of unstable emulsion compatibility and poor batch stability, and achieve excellent thickening response performance and strong emulsion stability. , the effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

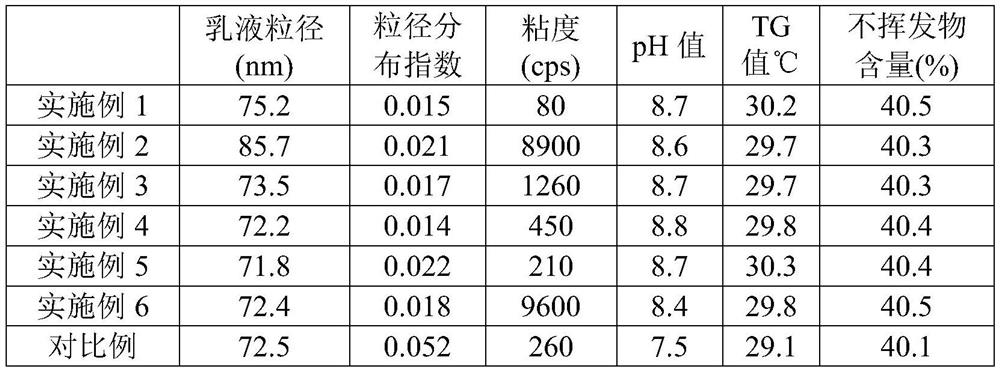

Examples

preparation example Construction

[0039] The embodiment of the present invention provides a method for preparing a two-in-one emulsion for colorful paint, comprising the following steps:

[0040] A) Mix 200-325 parts of deionized water with 0.065-7.5 parts of reactive emulsifier and 0.325-7.5 parts of anionic emulsifier to obtain an emulsifier solution;

[0041] B) Mix 0.1-5 parts of acid monomer, 1-10 parts of amino monomer, 1-50 parts of nitrile monomer, 1-50 parts of hydrophilic monomer and 350-450 parts of main monomer, and stir Add it into the emulsifier solution under the conditions to disperse, the dispersion time is 25-35min, obtain the dispersion liquid, and divide the dispersion liquid into the first dispersion liquid and the second dispersion liquid in proportion, the first dispersion liquid, the second dispersion liquid The two dispersions account for 1-6% and 94-99% of the total weight of the dispersion respectively;

[0042] C) Add 150-325 parts of deionized water, 0.025-3.5 parts of reactive em...

Embodiment 1

[0057] A two-in-one emulsion for colorful paints, comprising the following components in parts by weight: 598.5 parts of deionized water, 2 parts of reactive emulsifier, 2 parts of anionic emulsifier, 2 parts of acidic monomer, amine-based monomer 10 parts, 5 parts of hydrophilic functional monomer, 365 parts of main monomer, 0.5 part of buffer salt, 1.5 parts of initiator, 10 parts of silane coupling agent, 1.5 parts of pH regulator, 1 part of defoamer, 1 part of preservative .

[0058] The reactive emulsifier is selected from 2 parts of alkyl allyl succinate sodium sulfonate;

[0059] Described anionic emulsifier selects 2 parts of sodium lauryl sulfate for use;

[0060] Described acidic monomer selects 2 parts of methacrylic acid for use;

[0061] The amine-based monomer is selected from 10 parts of acrylamide;

[0062] The hydrophilic functional monomer is selected from 5 parts of hydroxyethyl methacrylate;

[0063] The main monomer is selected from 225 parts of methyl...

Embodiment 2

[0076] A two-in-one emulsion for colorful paints, comprising the following components in parts by weight: 598.5 parts of deionized water, 2 parts of reactive emulsifier, 2 parts of anionic emulsifier, 2 parts of acidic monomer, amine-based monomer 10 parts, 5 parts of hydrophilic functional monomer, 365 parts of main monomer, 0.5 part of buffer salt, 1.5 parts of initiator, 10 parts of silane coupling agent, 1.5 parts of pH regulator, 1 part of defoamer, 1 part of preservative .

[0077] The reactive emulsifier is selected from 2 parts of alkyl allyl succinate sodium sulfonate;

[0078] Described anionic emulsifier selects 2 parts of sodium lauryl sulfate for use;

[0079] Described acidic monomer selects 2 parts of methacrylic acid for use;

[0080] The amine-based monomer is selected from 10 parts of acrylamide;

[0081] The hydrophilic functional monomer is selected from 5 parts of hydroxyethyl methacrylate;

[0082] The main monomer is selected from 225 parts of methyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com