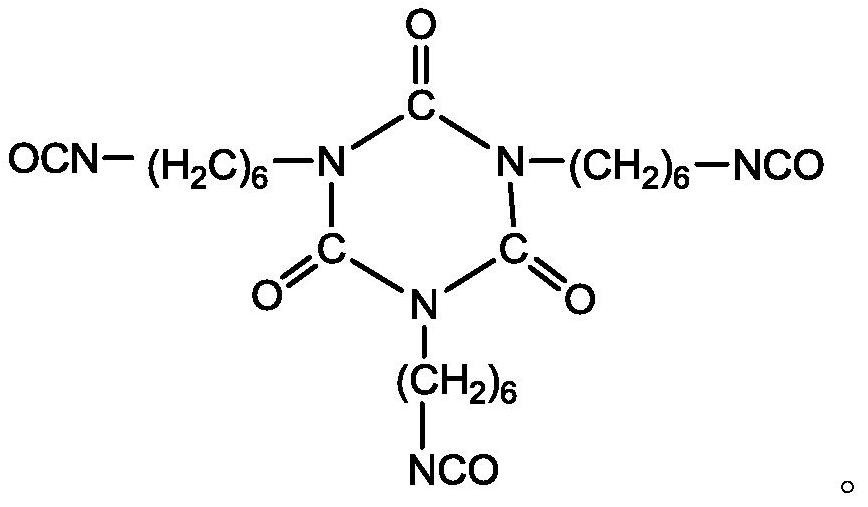

Light-cured polyurethane associated thickener as well as preparation method and application thereof

An associative thickener, polyurethane technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of poor structural controllability, general thickening efficiency, and high raw material cost, achieve low raw material cost, improve physical and mechanical properties, Good thickening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

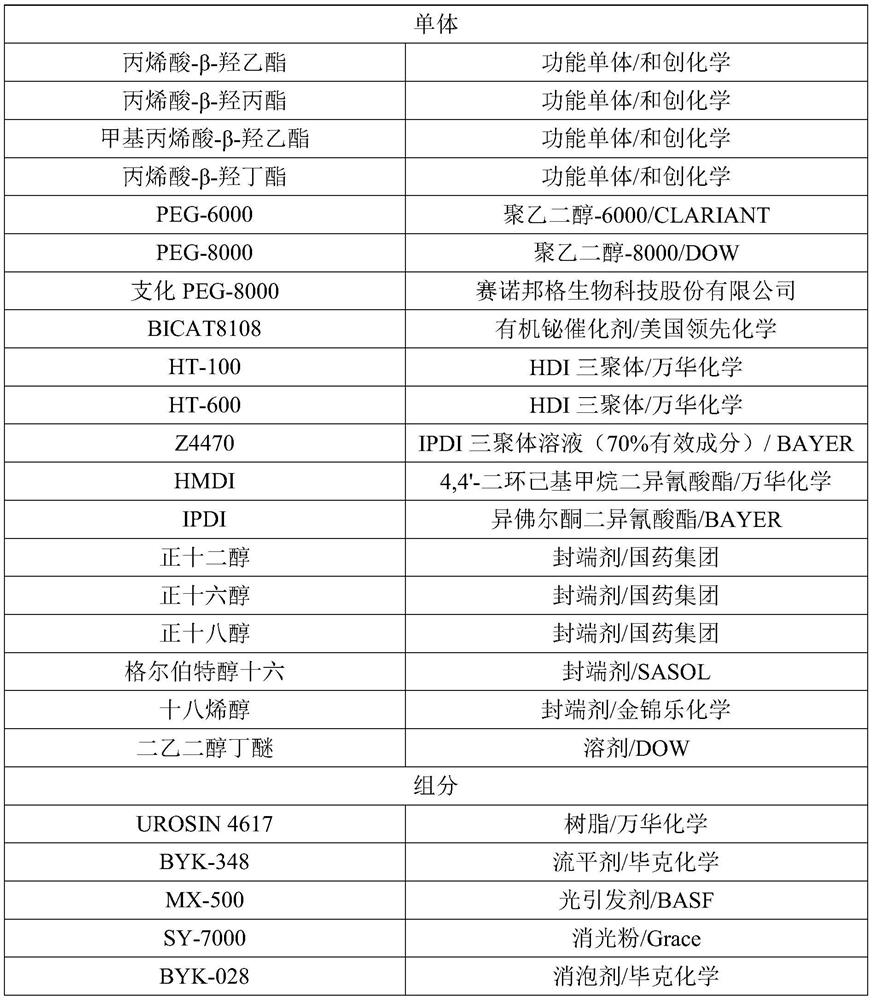

Embodiment 1

[0052] (1) Weigh β-hydroxyethyl acrylate (11.61g) and HT-600 (58.56g) according to the molar ratio of -OH to -NCO 1:3.2. Ethyl ester was slowly added dropwise into HT-600 dissolved with 1.75wt% BICAT8018, and kept at 40°C for 2.0h to obtain a colorless or light yellow isocyanate adduct containing active C=C.

[0053] (2) Weigh polyether polyol PEG-8000 (176g) and isocyanate adduct (7.02g) according to the molar ratio of -OH to -NCO 2:1, and first vacuum dehydrate the polyether polyol at 110°C 1h to make the water content lower than 500ppm, then, under the protection of inert gas, add the dehydrated polyether polyol to the isocyanate adduct, and keep the reaction at 75°C for 1h to obtain a polyurethane prepolymer containing terminal hydroxyl groups .

[0054] (3) Weigh n-hexadecanol (5.34g) and HMDI (5.77g) according to the molar ratio of polyether polyol to n-hexadecanol and HMDI 1:1:1, and under inert gas protection, n-hexadecanol Add it into the polyurethane prepolymer and...

Embodiment 2

[0056] (1) Weigh β-hydroxypropyl acrylate (13.01g) and HT-600 (58.56g) according to the molar ratio of -OH to -NCO 1:3.2, and mix β-hydroxypropyl acrylate (13.01g) with 30min under the protection of inert gas Propyl ester was slowly added dropwise into HT-600 dissolved with 1.75wt% BICAT8018, and kept at 60°C for 1.0h to obtain a colorless or light yellow isocyanate adduct containing active C=C.

[0057] (2) Weigh polyether polyol PEG-6000 (198g) and isocyanate adduct (7.16g) according to the molar ratio of -OH to -NCO of 3:1, and first vacuum dehydrate the polyether polyol at 110°C 1h to make the water content lower than 500ppm, then, under the protection of inert gas, add the dehydrated polyether polyol to the isocyanate adduct, and keep the reaction at 75°C for 1h to obtain a polyurethane prepolymer containing terminal hydroxyl groups .

[0058] (3) Weigh Guerbet alcohol sixteen (5.34g) and HMDI (8.66g) according to the molar ratio of polyether polyol to Guerbet alcohol si...

Embodiment 3

[0060] (1) Weigh β-hydroxyethyl acrylate (11.61g) and HT-600 (58.56g) according to the molar ratio of -OH to -NCO 1:3.2. Ethyl ester was slowly added dropwise into HT-600 dissolved with 2.5wt% BICAT8018, and kept at 40°C for 2.0h to obtain a colorless or light yellow isocyanate adduct containing active C=C.

[0061] (2) Weigh polyether polyol PEG-6000 (264g) and isocyanate adduct (7.02g) according to the molar ratio of -OH to -NCO of 4:1, and first vacuum dehydrate the polyether polyol at 110°C 1h to keep the water content below 500ppm, then, under the protection of an inert gas, add the dehydrated polyether polyol to the isocyanate adduct, and keep it at 45°C for 2.5h to obtain a polyurethane prepolymer containing terminal hydroxyl groups. things.

[0062] (3) Weigh n-dodecyl alcohol (4.10g) and IPDI (9.78g) according to the molar ratio of polyether polyol to n-dodecyl alcohol and IPDI 2:1:2, under inert gas protection, n-dodecyl alcohol Add it into the polyurethane prepoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com