Reaction viscosity adjusting composition suitable for two-component waterborne epoxy system as well as preparation method and application of reaction viscosity adjusting composition

A water-based epoxy and viscosity adjustment technology, applied in the direction of epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problem of reducing the physical and mechanical properties and chemical resistance of the paint film, not having reactivity, and unable to participate in two-component Problems such as cross-linking reaction of water-based epoxy system to achieve excellent physical and mechanical properties and chemical resistance, improve physical and mechanical properties and chemical resistance, and high thickening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

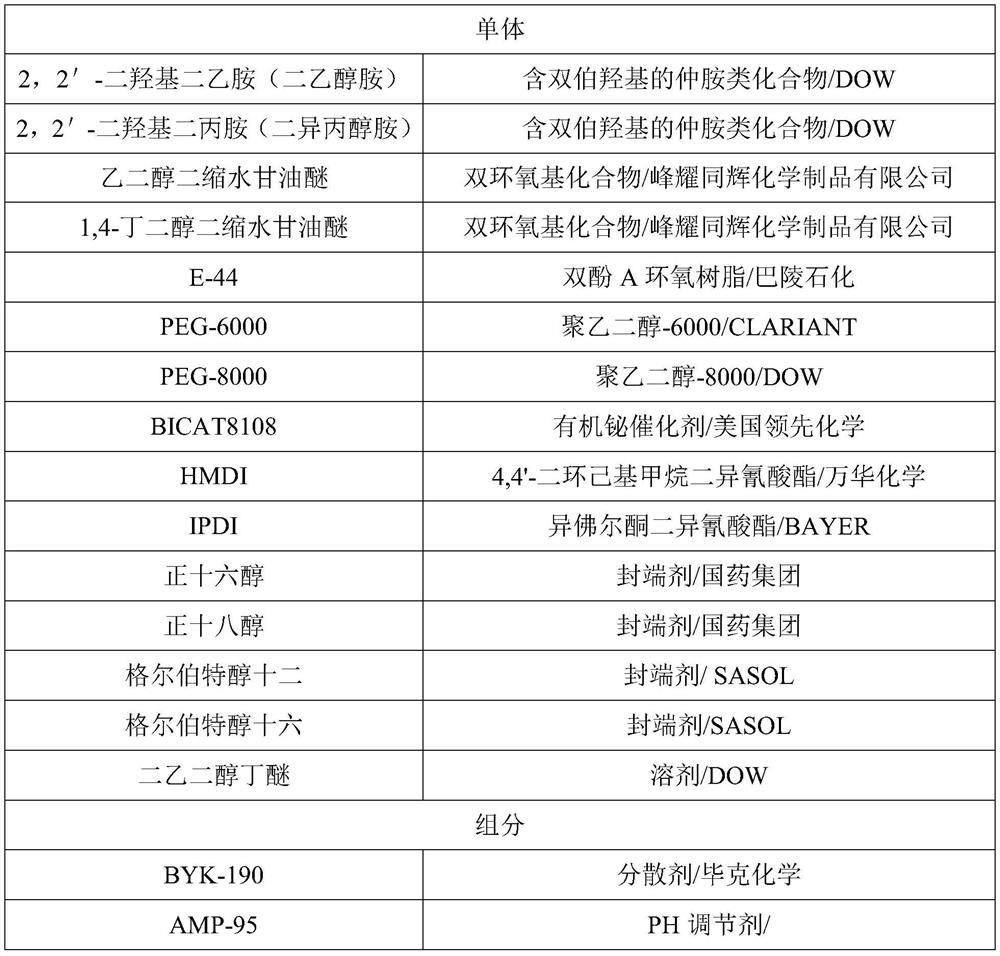

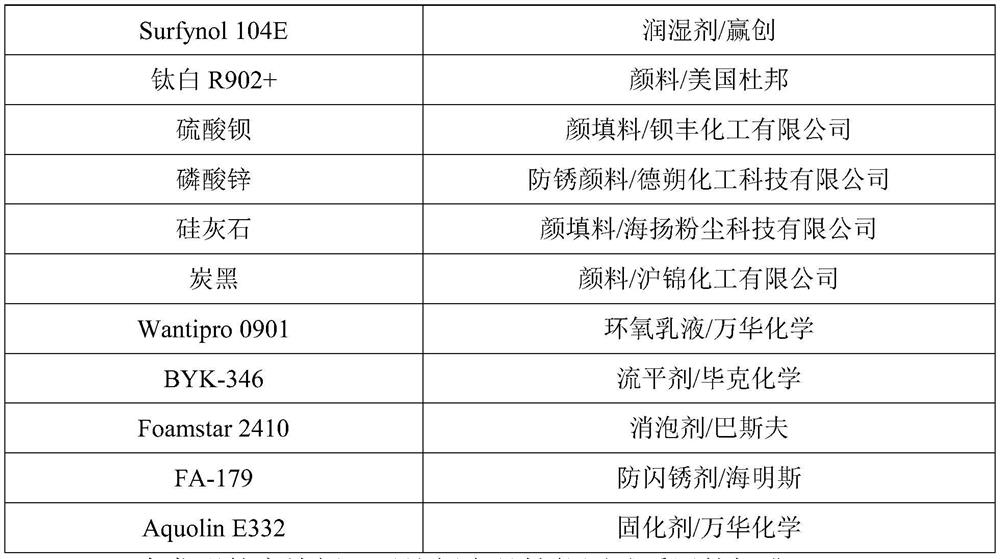

Method used

Image

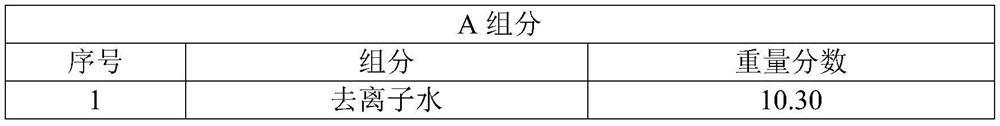

Examples

Embodiment 1

[0047] (1) Under the protection of nitrogen, take 73.16g of ethylene glycol diglycidyl ether (0.42mol) and add it to 250ml three-mouth burner, heat it to 55°C, and slowly add 42.06g of diethanolamine (0.4mol) to ethylene glycol In the diglycidyl ether, the dropping time is controlled at about 1 hour, and after the dropping is completed, the insulation reaction is carried out for 2 hours to obtain a monoepoxide intermediate product containing 2 primary hydroxyl groups;

[0048] (2) Under the protection of nitrogen, take 120g of PEG-6000 (0.02mol), 2.88g of the intermediate product of step (1) (calculated as diethanolamine is 0.01mol) into a 1L four-necked flask and stir evenly, heat to 75°C, and 10.49g of HMDI (0.04mol) and 0.26g of BiCAT8108 were added to the flask and incubated for 2h.

[0049] (3) After the reaction in step (2) is finished, take 4.85g Guerbet alcohol hexadecanol (0.02mol) and add it into the flask to continue the insulation reaction for 2h, then, use 138.22g...

Embodiment 2

[0051] (1) Under the protection of nitrogen, take 100.00g of epoxy resin E-44 (0.22mol) and add it to 250ml three-mouth burner, heat it to 75°C, and slowly add 21.03g of diethanolamine (0.2mol) into E-44 , the dropping time is controlled at about 1h, and after the dropping is completed, the insulation reaction is carried out for 3h to obtain a monoepoxy intermediate product containing 2 primary hydroxyl groups;

[0052] (2) Under the protection of nitrogen, take 120g of PEG-8000 (0.015mol), 9.08g of the intermediate product of step (1) (calculated as diethanolamine as 0.015mol) into a 1L four-necked flask and stir evenly, heat to 85°C, and 10.00g of IPDI (0.045mol) and 0.26g of BiCAT8108 were added to the flask and incubated for 2h.

[0053] (3) After the reaction in step (2) is finished, take 5.59g Guerbet alcohol twelve (0.03mol) and add to the flask to continue the insulation reaction for 2h, then, use 144.67g diethylene glycol butyl ether and 434.01g deionized water The h...

Embodiment 3

[0055] (1) Under the protection of nitrogen, take 101.13g of butanediol glycidyl ether (0.50mol) and add it to 250ml three-port burnt product, heat it to 75°C, and slowly add 53.28g of diisopropanolamine (0.40mol) to the butane In the glycol glycidyl ether, the dropping time is controlled at about 1h, and after the dropping is completed, the reaction is incubated for 3h to obtain a monoepoxide intermediate product containing 2 primary hydroxyl groups;

[0056] (2) Under the protection of nitrogen, take 120g of PEG-6000 (0.02mol), 1.93g of the intermediate product of step (1) (calculated as diethanolamine as 0.005mol) into a 1L four-necked flask and stir evenly, heat to 85°C, and 7.87g of HMDI (0.03mol) and 0.26g of BiCAT8108 were added to the flask and incubated for 2h.

[0057] (3) After the reaction in step (2) finishes, get 2.43g n-hexadecanol (0.01mol) and add into the flask to continue the insulation reaction for 2h, then, use 132.23g diethylene glycol butyl ether and 396...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com