High strength combination column

A high-strength, composite column technology, applied in the field of composite columns, can solve problems such as heavy weight, complex structure, and difficult assembly, and achieve the effects of light weight, flexible installation, and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

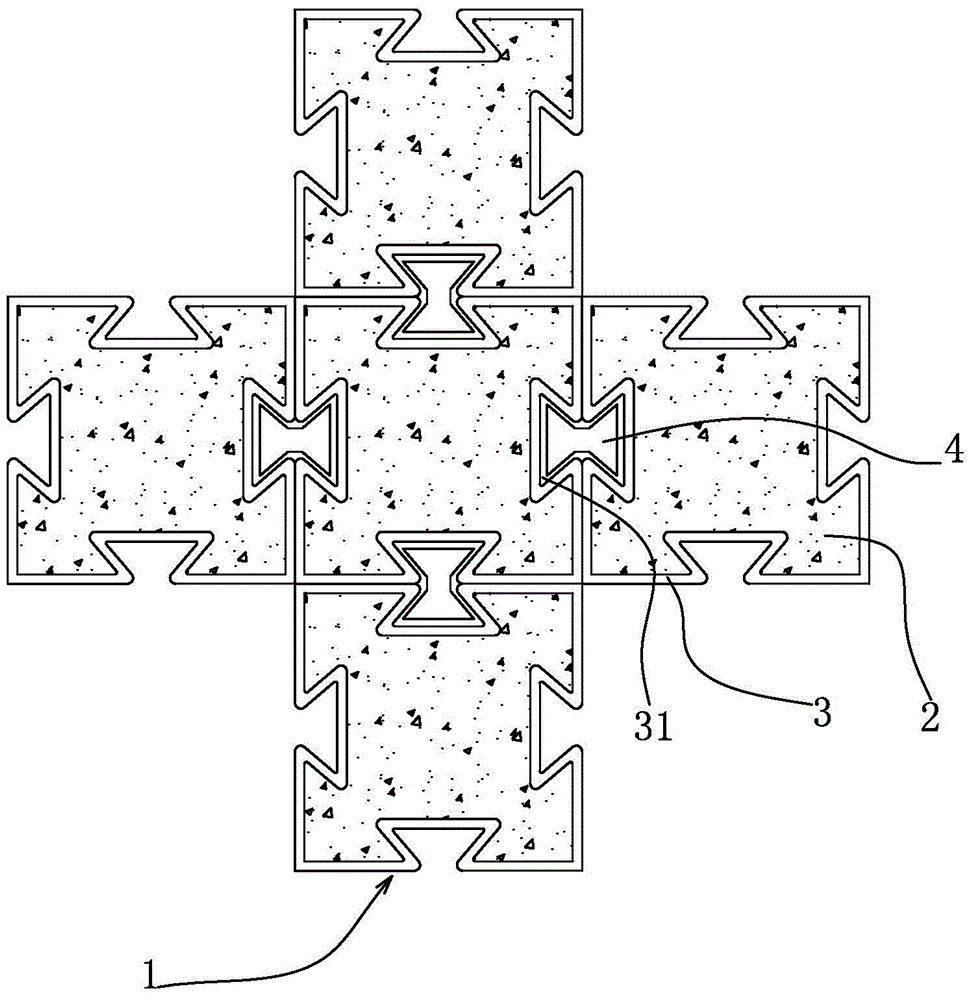

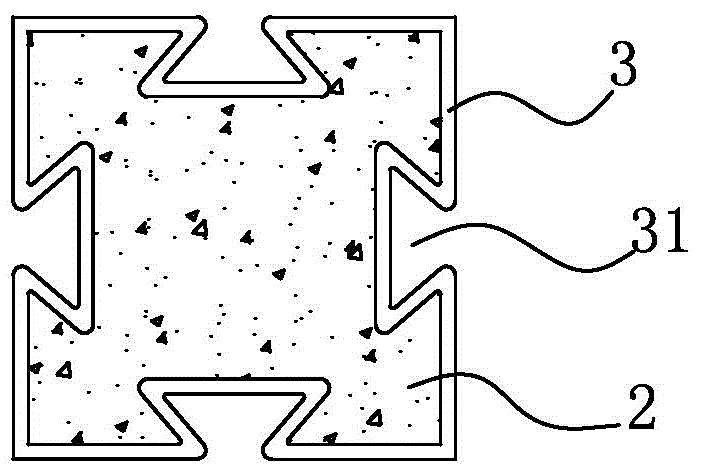

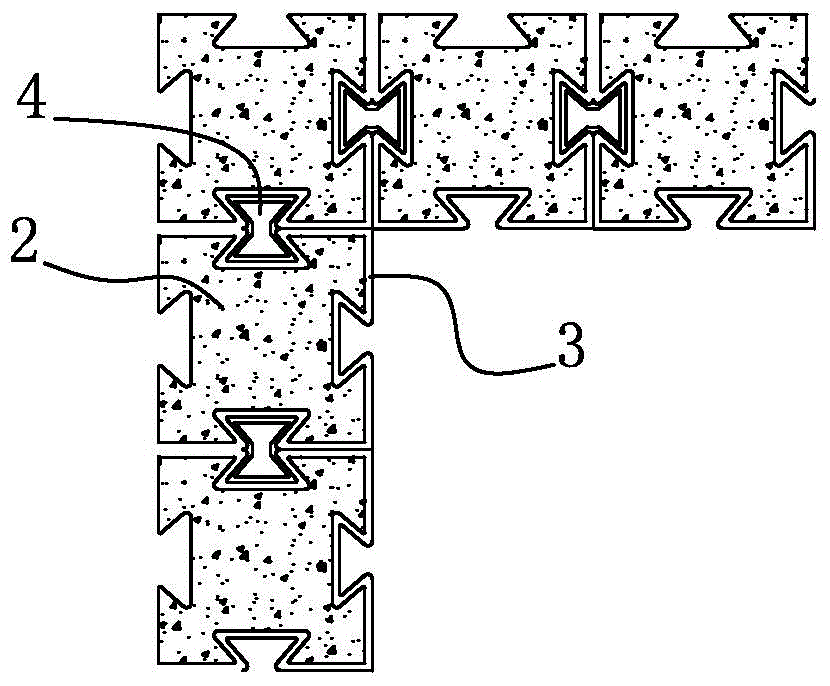

[0019] see figure 1 and figure 2 In the embodiment of a high-strength composite column given in the present invention, it includes a high-strength keel 1 made of metal materials and a filling material 2, the keel 1 is spliced by a plurality of basic parts 3, and the basic The part 3 is a hollow cylindrical structure, and the adjacent basic parts 3 are connected together, and the cavity of the basic part 3 is filled with the filling material 2 . The keel 1 in the present invention has relatively high strength, which is equivalent to or higher than that of traditional reinforced concrete composite columns, that is, the keel can meet the strength requirements of the composite column. The basic element 3 is a basic unit constituting a composite column, and a plurality of basic elements 3 are used to connect together to form a required composite column according to the design strength requirements and shape. The weight of a single basic component 3 is relatively light, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com