Separator for aerated concrete light bricks

A technology of aerated concrete and lightweight bricks, applied in ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of low work efficiency, high cost of separators, high power consumption, etc., and achieve cost reduction and flexible movement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

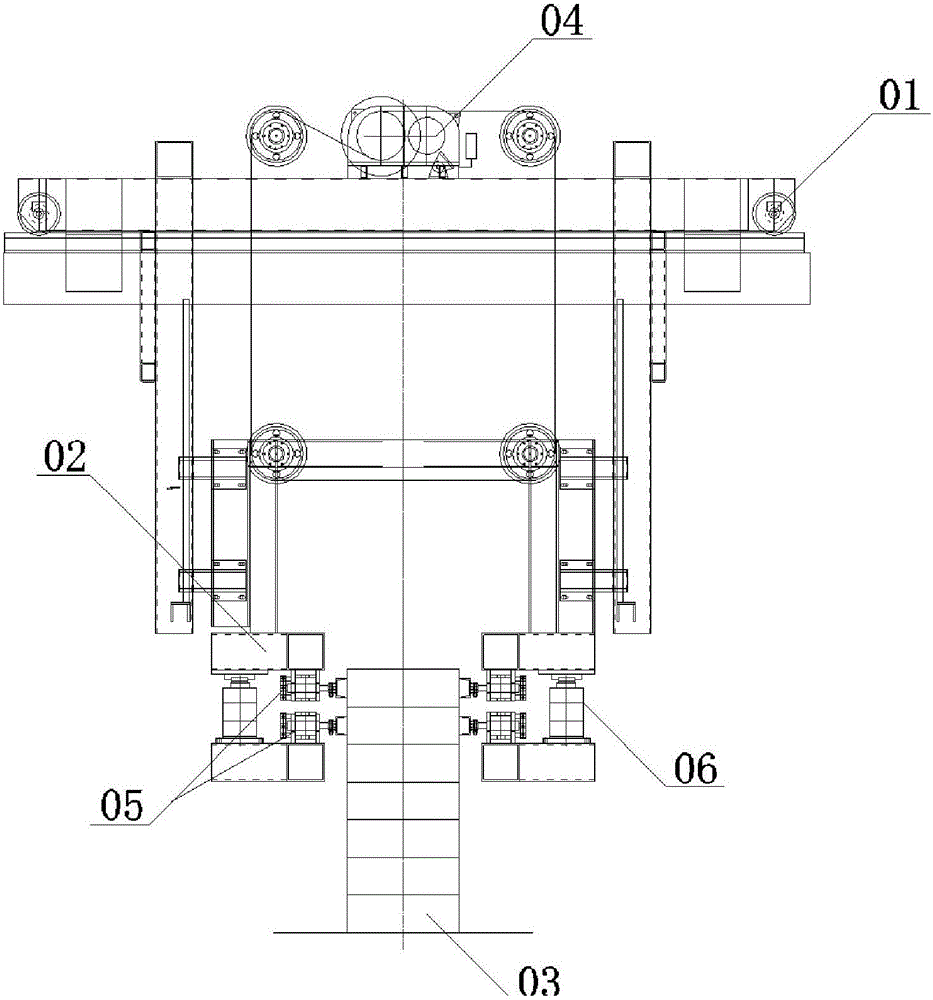

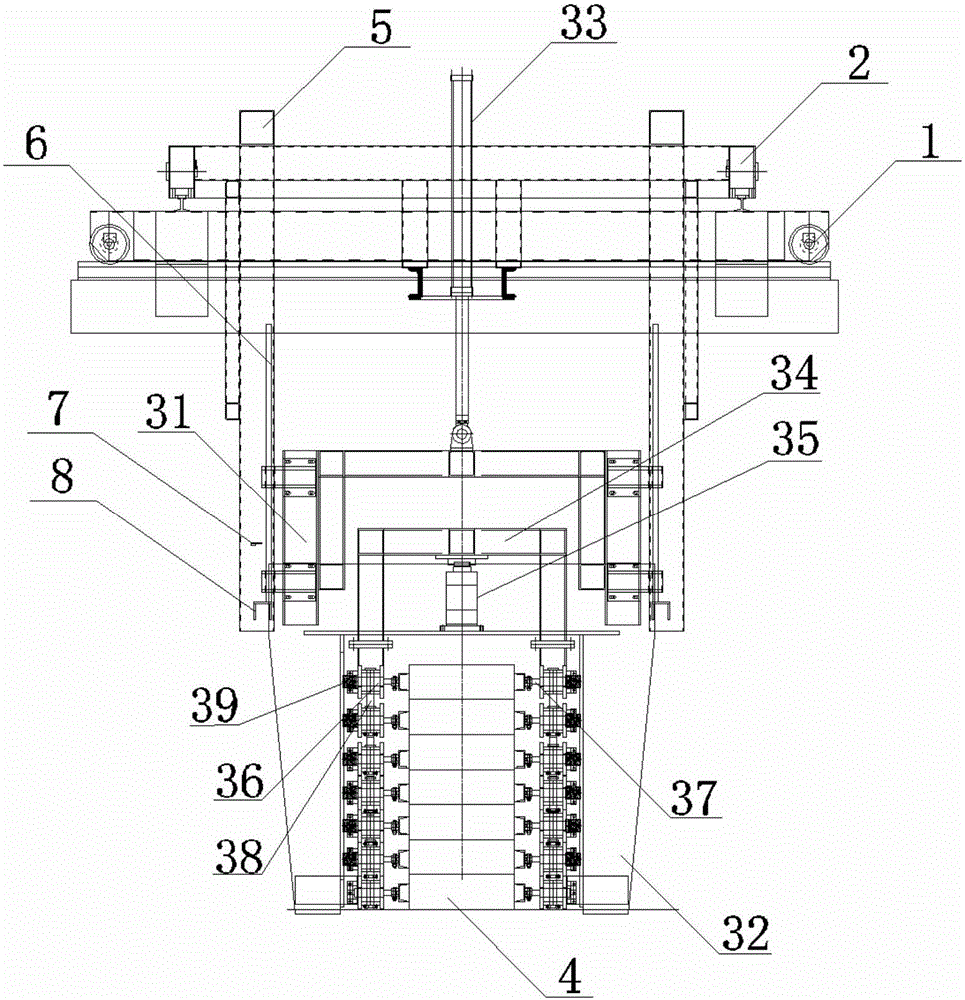

[0029] see figure 2 , a kind of aerated concrete lightweight brick separator, comprising a front and rear sliding crown 1, a left and right sliding crown 2 fixed on the front and rear sliding crown 1, and a body fixed on the left and right sliding crown 2. The body includes a lifting frame 31, a fixed plate 32 fixed to the lifting frame 31, a lifting oil cylinder 33 for driving the lifting frame 31 to move up and down, a brick clamping frame 34, a loose brick oil cylinder 35 connecting the lifting frame 31 and the brick clamping frame 34 respectively, Several groups of clamping brick seats 36 matched with the quantity of light bricks 4 to be separated and several groups of brick clamping oil cylinders 37 correspondingly arranged on the brick clamping seats 36. Clamping brick seat 36 comprises the first gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com