Intelligent sorting equipment for small-batch sheet type scattered devices

A small batch, bulk material technology, applied in sorting and other directions, can solve the problems of manual sorting, the inability of automatic sorting by chip bulkers, low efficiency, etc., to achieve convenient operation and transfer, clear assembly structure, The effect of the explicit function of the module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

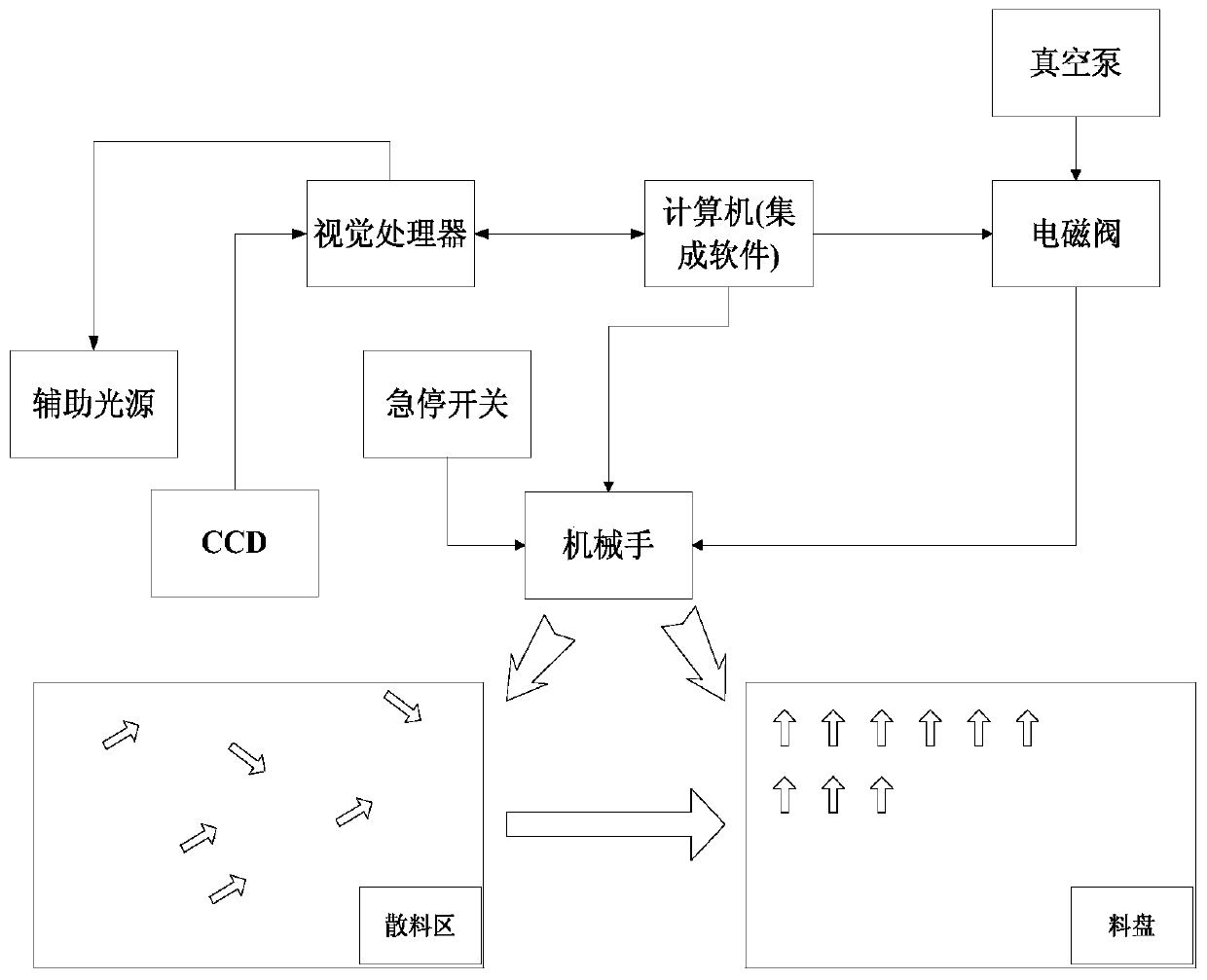

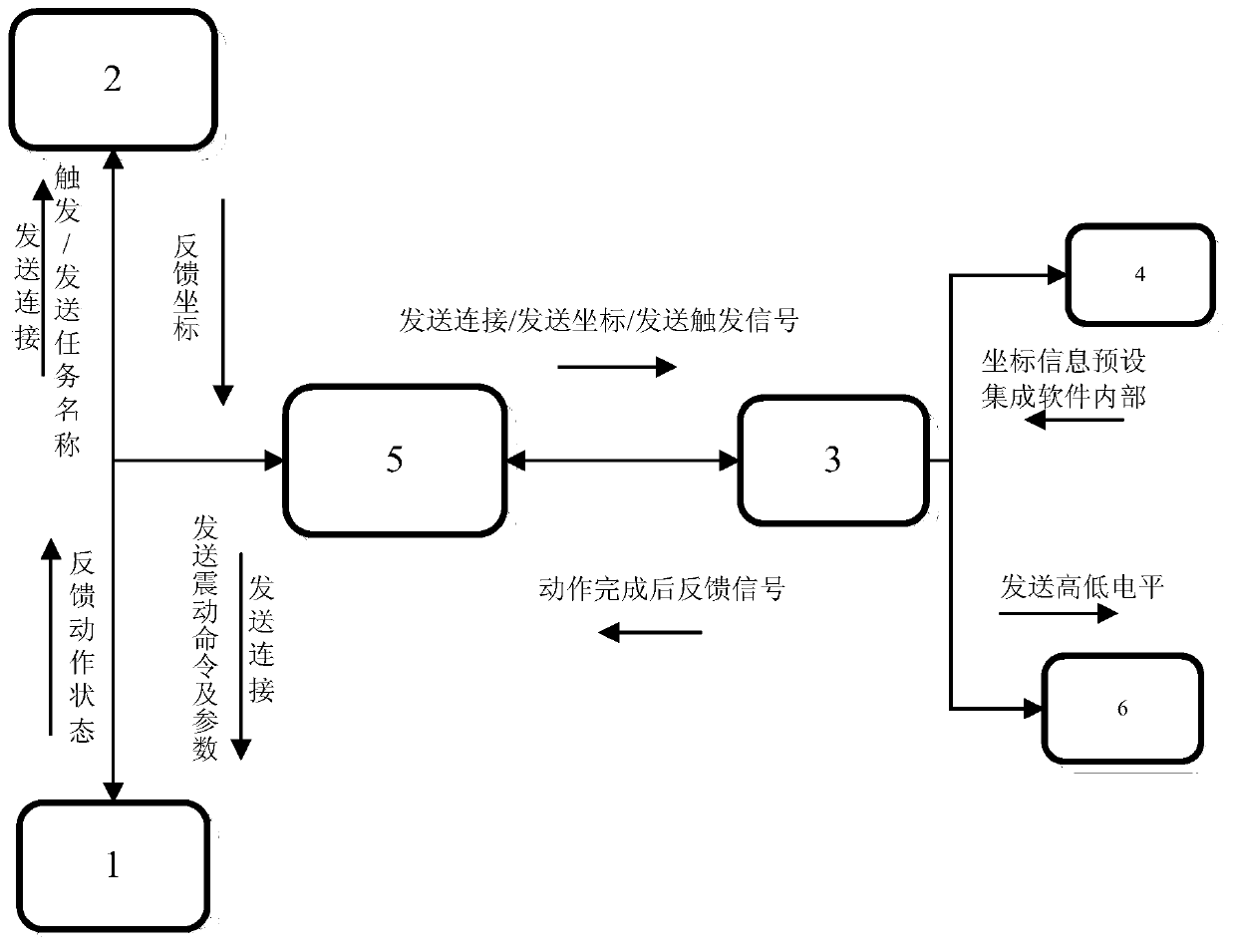

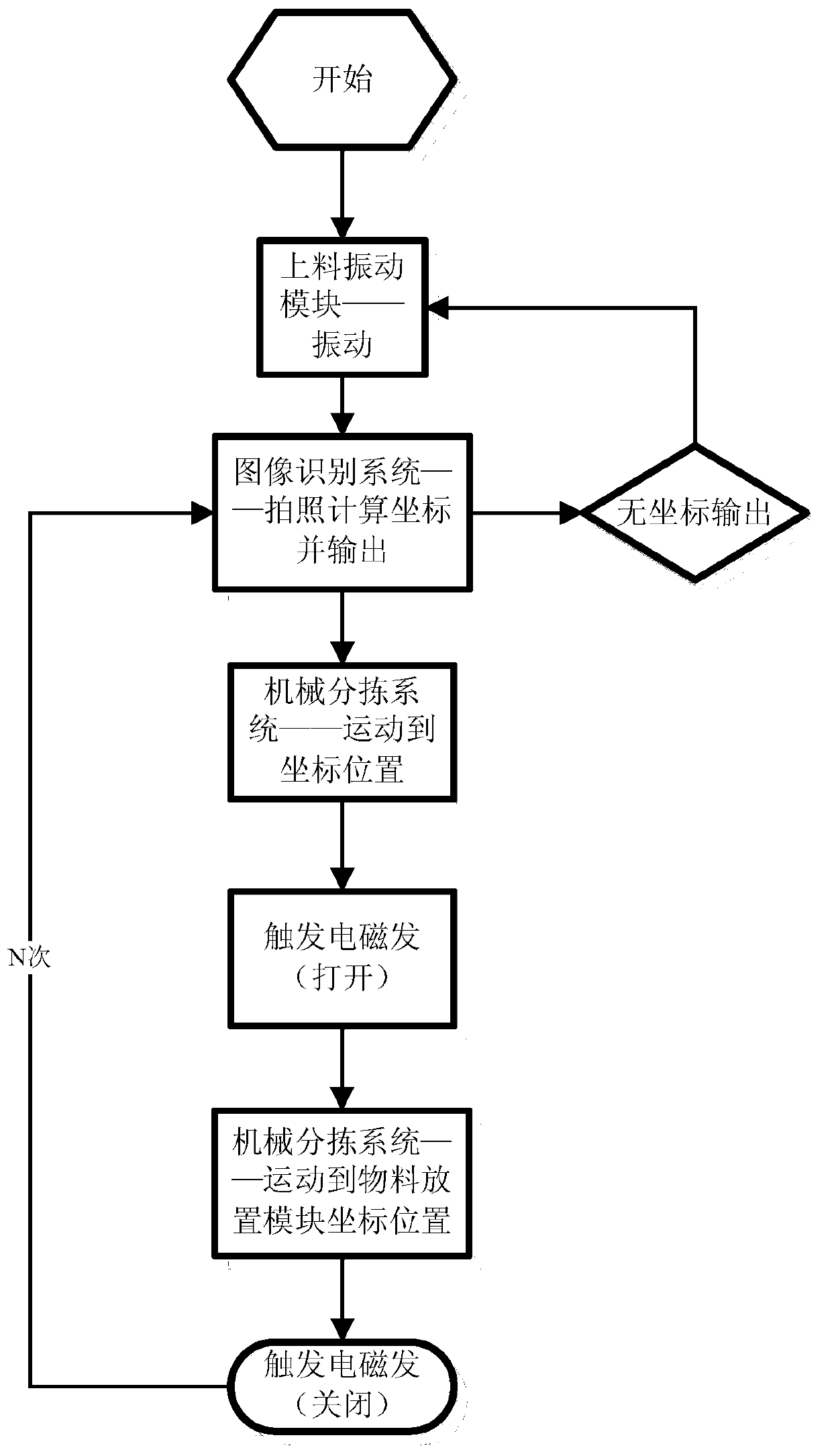

[0027] Such as figure 1 , 2 , 3, in this example, taking the sorting 0402 package as an example, the six functions of the intelligent sorting equipment for chip bulk electronic devices include: feeding vibration module 1, image recognition system 2, mechanical sorting system 3. The material placement module 4, the integrated software 5, and the auxiliary actuator 6 are introduced and used.

[0028] 1) According to the sorting requirements and functional requirements, develop integrated software. The integrated software 5 is the link connecting each module and also the command transmission link. The key to realize the sorting function lies in the writing of software logic, the setting of commands and the expansion of functions. The software in this system is written in C++ language; the corresponding sorting parameters of different packages are configured in the integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com