High precision self-centering external contracting type tensioning positioning mechanism

A positioning mechanism and self-centering technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of inability to achieve standardized inventory, reduce processing and supply time, and inability to achieve flexible changes and quick switching and disassembly, etc., to achieve Humanized design and layout, optimized test space, compact and beautiful structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

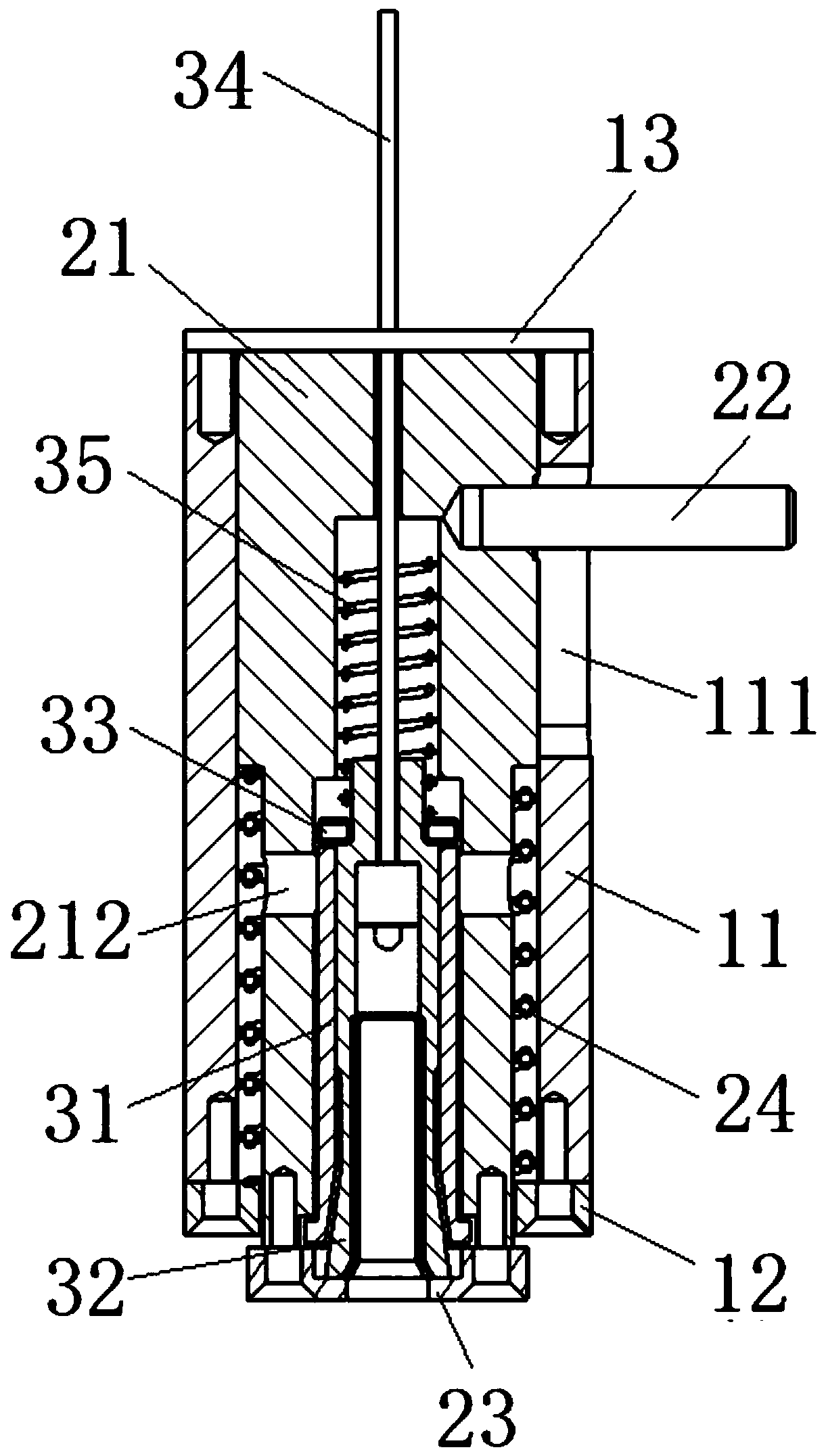

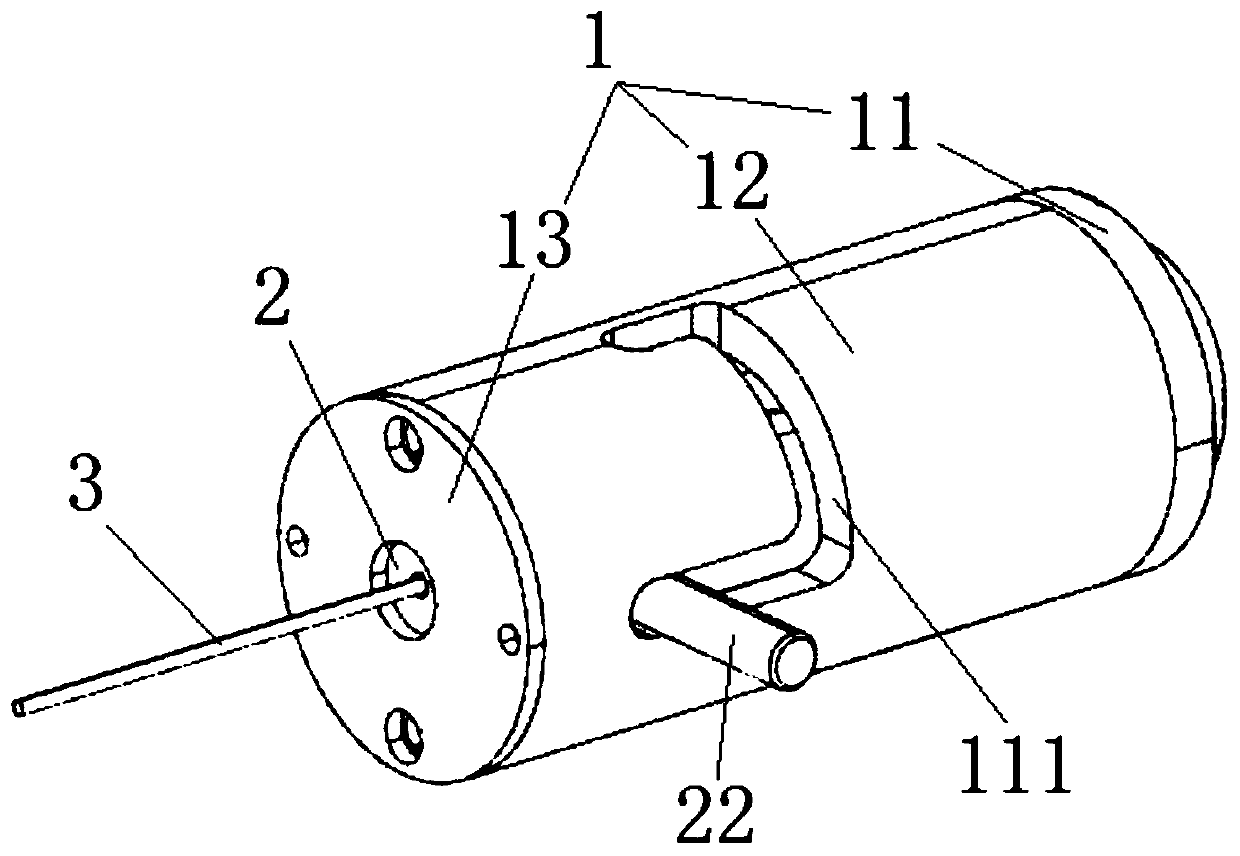

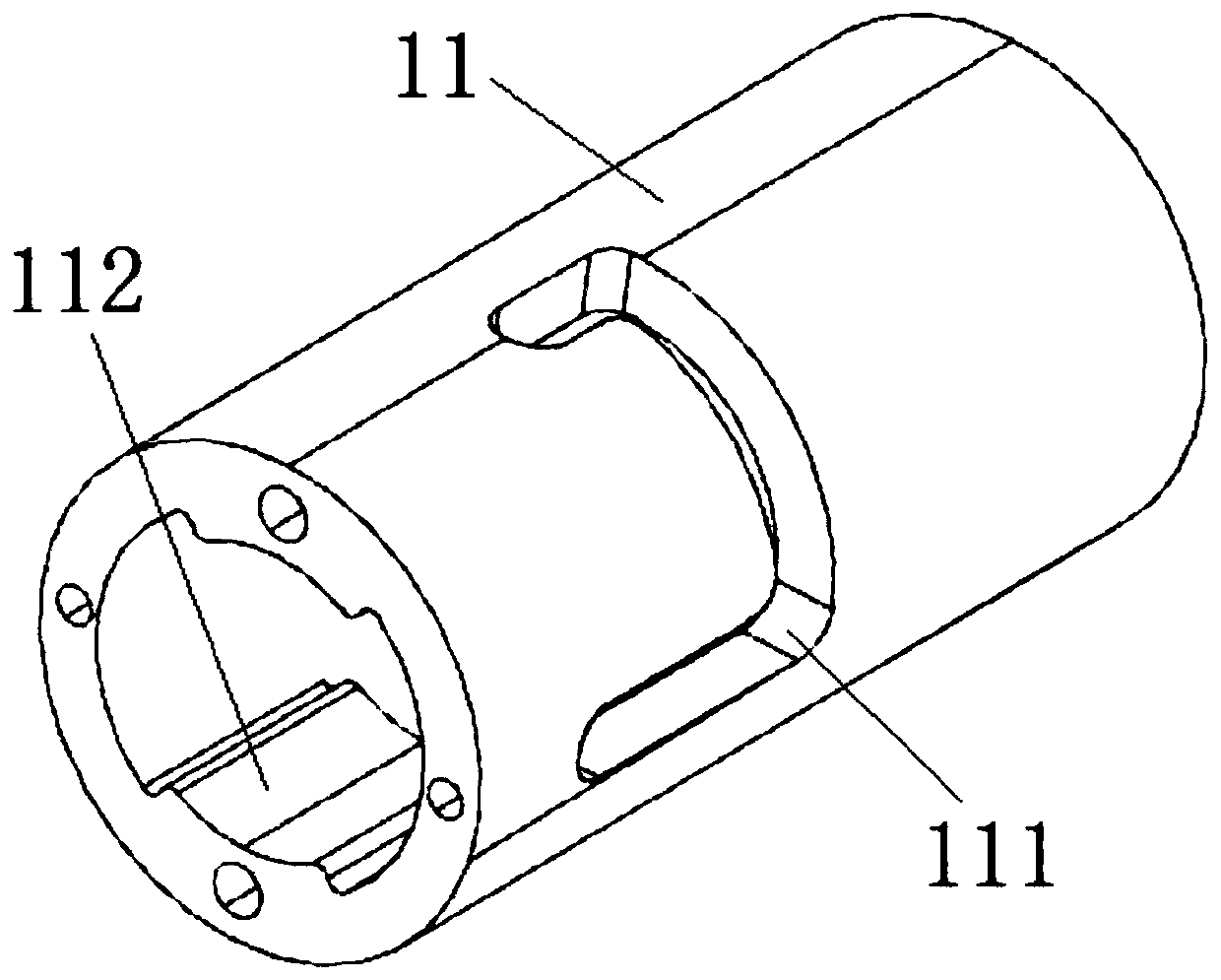

[0030] Such as Figure 1 to Figure 5 As shown, the present invention is a high-precision, self-centering, externally-wrapped tightening and positioning mechanism, which includes an axially hollow housing assembly 1, an axially telescopic compression assembly 2 that can be in the housing assembly 1, and The tightening assembly 3 in the compression assembly 2 is axially telescopic. The tightening assembly 3 includes a self-aligning sleeve 31 with an elastic sandwich core 32, a cable 34 connected to the elastic sandwich core 32 and passing through the upper part of the self-aligning sleeve 31, and The inner spring 35 used to return the aligning sleeve 31 to the lower position; the compression assembly 2 includes an axially hollow moving core seat 21, a moving pin 22 fixed on the outside of the moving core seat 21, and used to allow the moving core seat 21 to move The upper return outer spring 24; the housing assembly 1 includes a cylindrical body 11 provided with a motion track gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com