Installing and positioning device for fabricated-type prefabricated wall plate and installing and positioning method of installing and positioning device

A prefabricated wall panel, installation and positioning technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of low construction efficiency, high technical requirements, complex construction technology, etc., to improve construction efficiency and stability , The effect of quick installation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

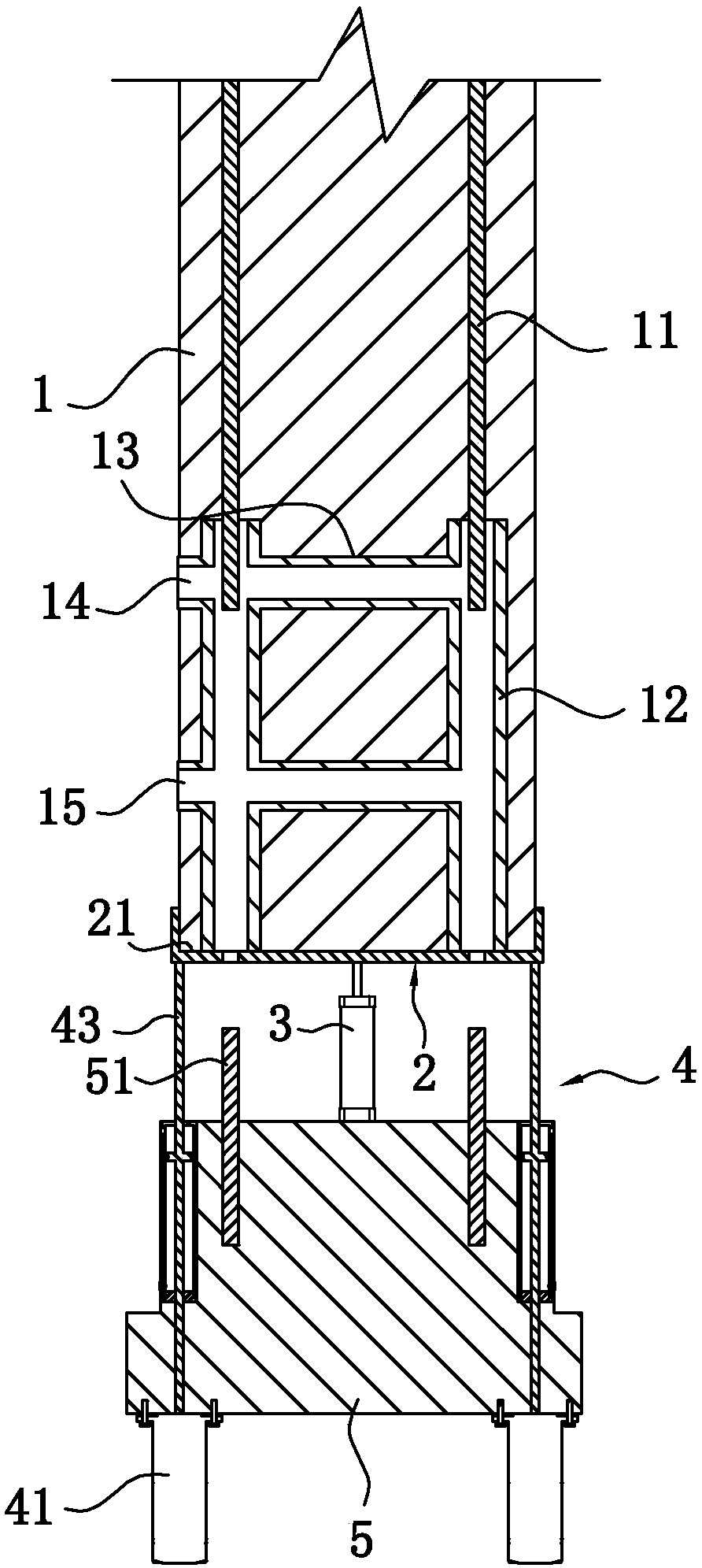

[0048] refer to figure 1 , an installation and positioning device for an assembled prefabricated wall panel, suitable for installation and positioning of a prefabricated wall panel 1 on a prefabricated beam 5 or a floor slab. In this embodiment, the prefabricated beam 5 is taken as the connecting member with the prefabricated wall panel 1 as an example.

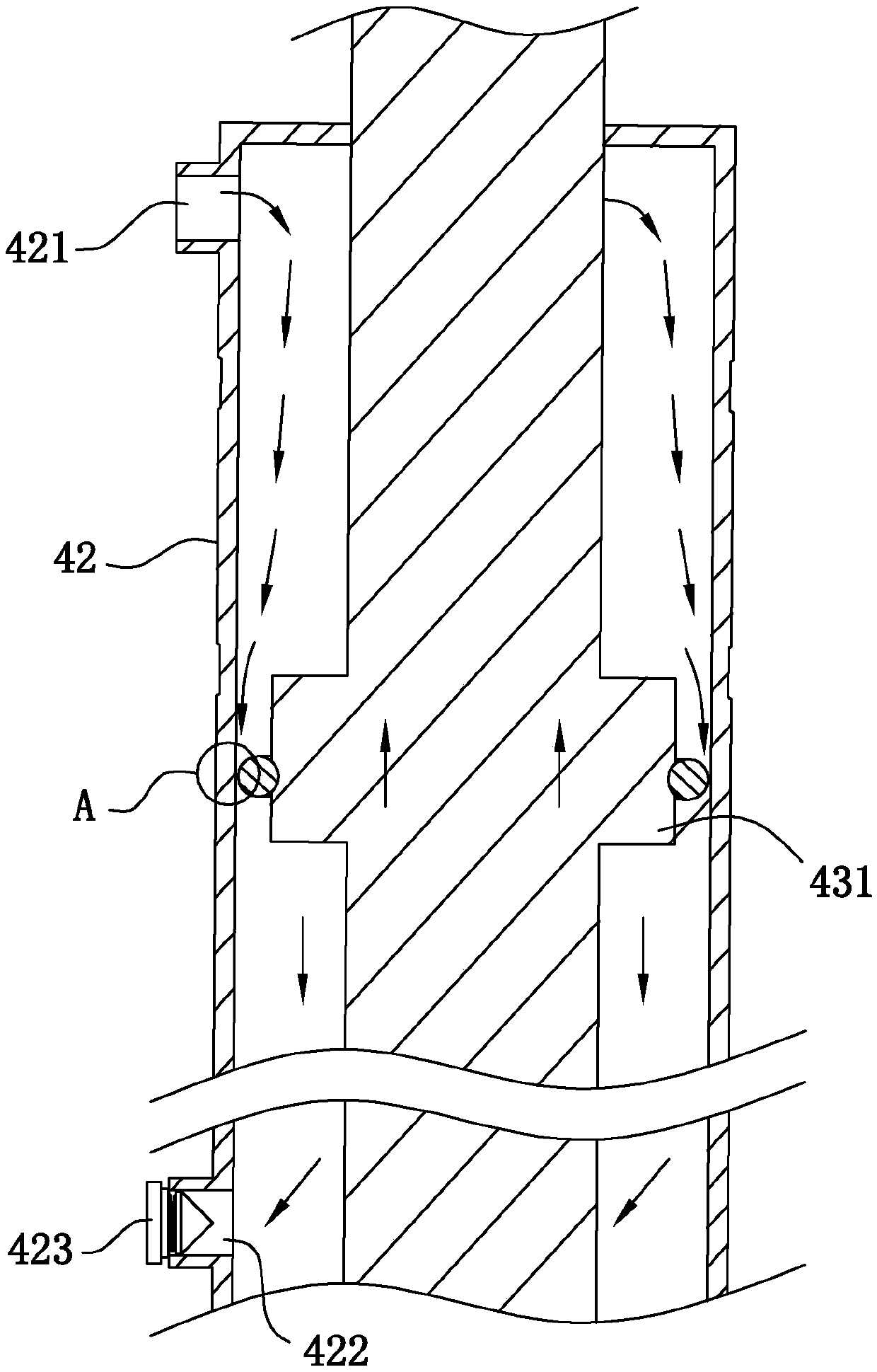

[0049] The installation and positioning device specifically includes a positioning beam 2 , a plurality of jacks 3 connected to the lower end surface of the positioning beam 2 and a plurality of retarding mechanisms 4 . Under the support of the jack 3, the positioning beam 2 realizes the overhead state with the prefabricated beam 5 below. The overhead distance depends on different working conditions and is realized by selecting different jack 3 models. The jack 3 supports and connects to the middle position of the positioning beam 2, and is arranged at intervals along the length direction of the positioning beam 2. The posi...

Embodiment 2

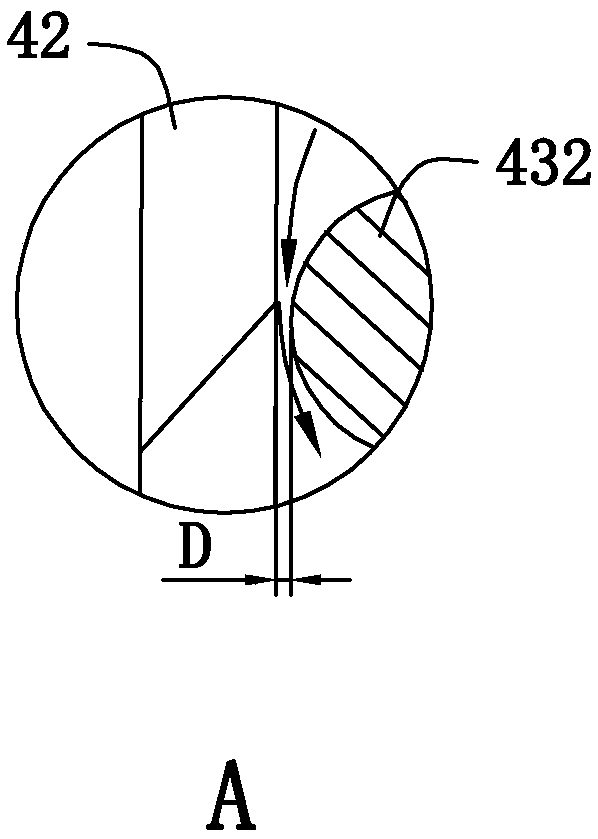

[0057] An installation and positioning device for an assembled prefabricated wall panel, the difference from the first implementation is that the structure of the second piston 433 provided on the support rod 43 is different, see Figure 6 , the second piston 433 is cup-shaped, and one side of its opening faces the outlet hole 422 (see figure 2 ), when the support rod 43 goes up, the second piston 433 is subjected to the impact of air entering from the air inlet 421 to make it retract, and the support rod 43 can go up smoothly; and when the support rod 43 goes down, refer to Figure 7 , the second piston 433 is subjected to the force of the air on the lower side, causing it to expand outward, and the contact area between the outer edge of the second piston 433 and the inner wall of the piston cylinder 42 increases with the increase of the downward stroke of the support rod 43, thereby playing a role The downward slowing effect on the support rod 43.

[0058] In particular, t...

Embodiment 3

[0060] An installation and positioning device for an assembled prefabricated wall panel. The difference from Embodiment 1 is that the retarding mechanism 4 adopts a gas spring, the cylinder body of the gas spring is pre-embedded in the prefabricated beam 5, and the piston rod of the gas spring moves from the prefabricated beam 5 The inner part extends out and connects with the lower end surface of the positioning beam 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com