Dual-colored cable three-layer co-extrusion device

A three-layer co-extrusion and cable technology, used in household components, household appliances, other household appliances, etc., can solve problems such as prolonging time, distinguishing adverse effects, and inconvenient product appearance, ensuring structural stability and improving convenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

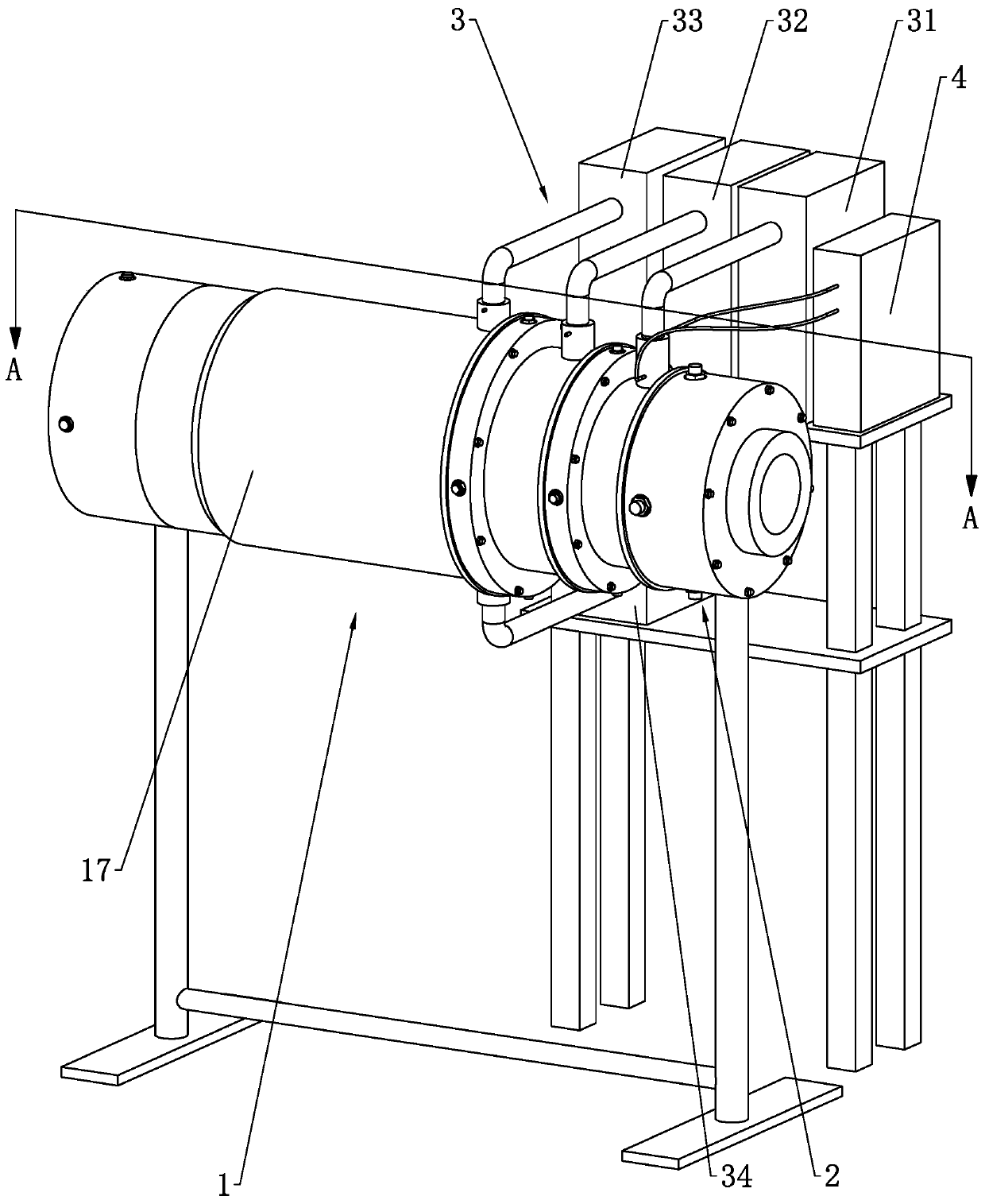

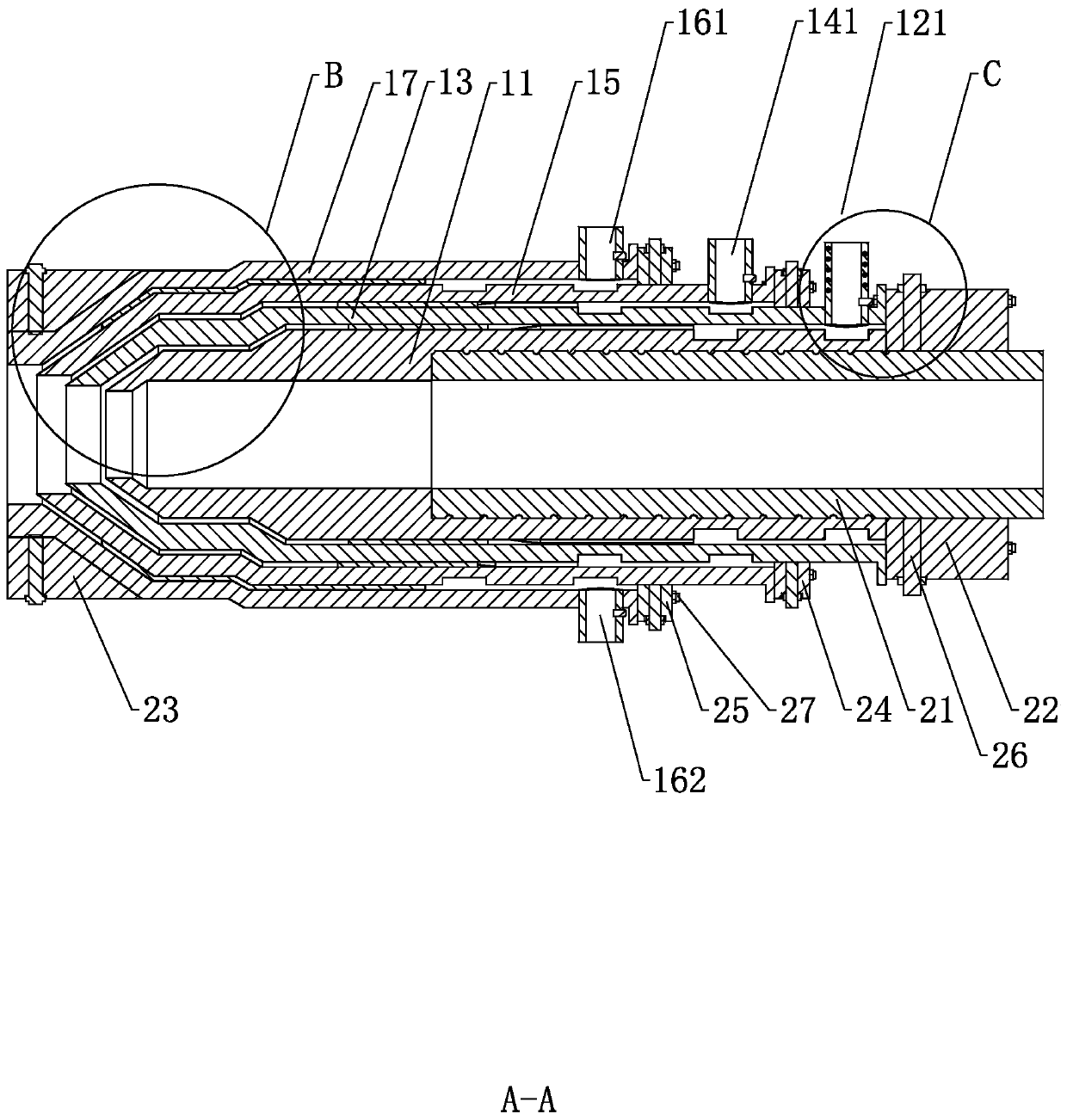

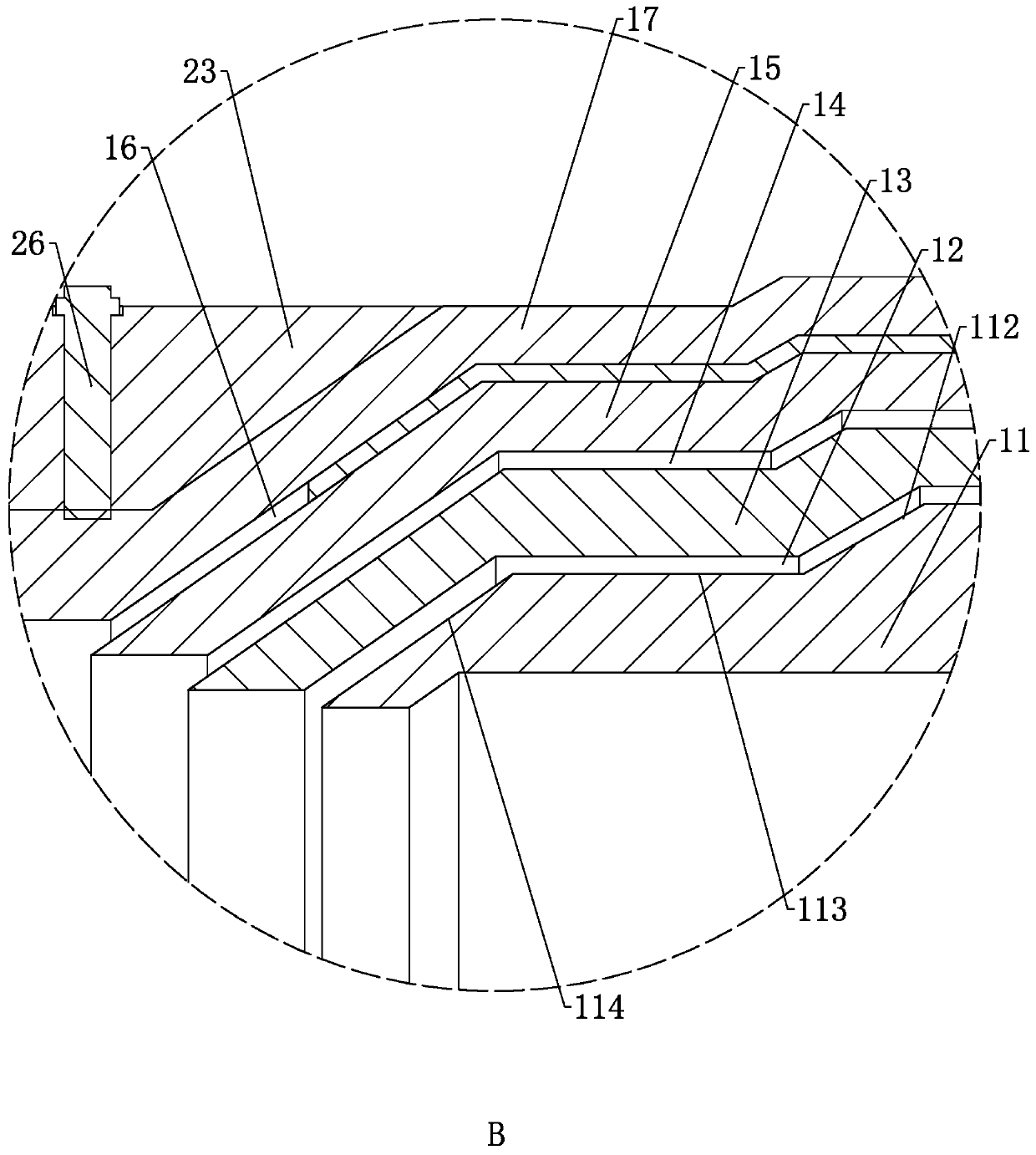

[0057] Reference figure 1 with figure 2 , Is a two-color cable three-layer co-extrusion device disclosed in the present invention, which includes a co-extrusion assembly 1 and a feeding assembly 3 connected to the co-extrusion assembly 1. The feeding assembly 3 includes an inner shielding layer material box 31 and an insulating layer material Box 32, first-level outer shielding layer tank 33, and second-level outer shielding layer tank 34. The co-extrusion assembly 1 is respectively provided with an inner shielding layer feeding pipe 121 for communicating with the inner shielding layer tank 31, and The insulating layer feeding pipe 141 connected to the insulating layer tank 32, the first-level outer shielding layer feeding pipe 161 for communicating with the first-level outer shielding layer tank 33, and the first-level outer shielding layer feeding pipe 161 for communicating with the second-level outer shielding layer tank 34 Secondary outer shielding layer feeding pipe 162. ...

Embodiment 2

[0081] The difference between this embodiment and the first embodiment is that the angle between the two planes formed by the longitudinal centerline of the two partitions 165 and the center axis of the secondary shunt mold 15 is 180°, and finally The boundary line between the first-level outer shielding layer and the second-level outer shielding layer formed on the outer shielding layer is clear and straight. The average number of variegated spots visible to the naked eye is 3 per 10 meters of the cable.

Embodiment 3

[0083] The difference between this embodiment and the first embodiment is that the included angle between the two planes formed by the longitudinal center lines of the two partitions 165 and the center axis of the secondary shunt mold 15 is 90°, one of which is The central angle of the first-level outer shielding layer is 90°, and the central angle of the second-level outer shielding layer is 270°. The boundary line between the upper-level outer shielding layer and the second-level outer shielding layer of the final outer shielding layer is fuzzy and existing Twisting phenomenon, the average number of noise points visible to the naked eye is 12 per 10 meters of the cable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com