Clean room easy to disassemble and assemble

A clean room and load-bearing column technology, applied in the field of clean room, can solve the problems of complex structure of clean room, occupation of space, increased cost of disassembly and assembly, etc., and achieve the effect of fast construction and disassembly, easy disassembly and assembly, and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

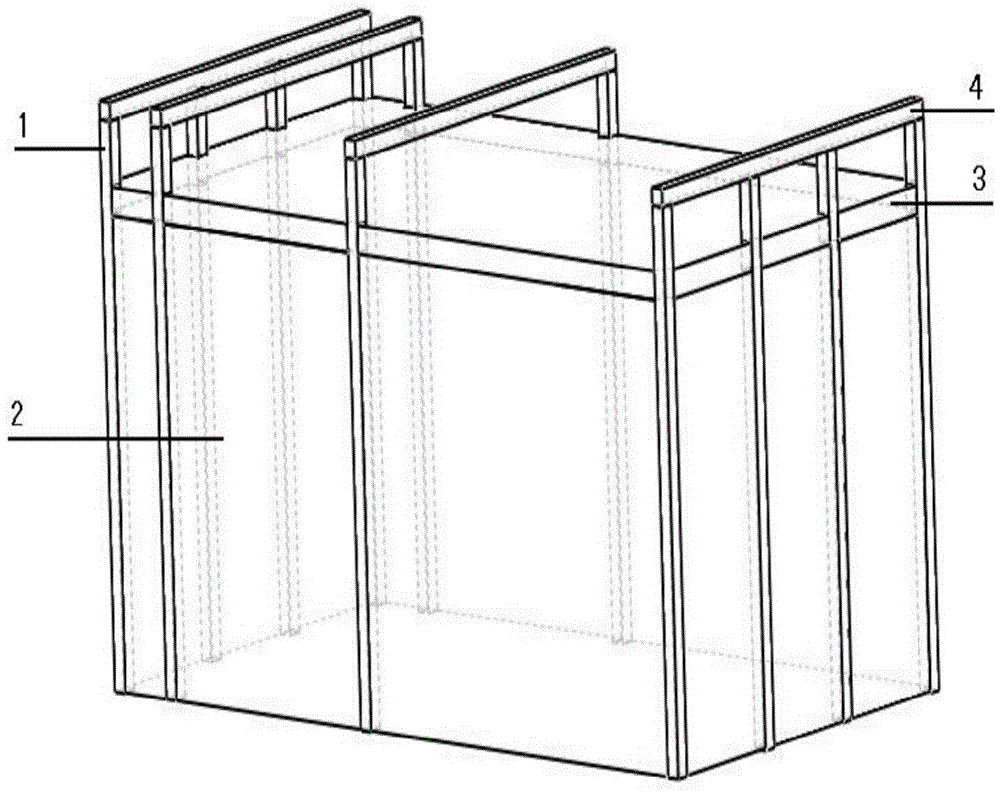

[0026] as attached figure 1 As shown, the height of the load-bearing column 1 is higher than the enclosure plate 2, and the top of the through hole of each load-bearing column 1 is clamped with a connecting groove, and a beam is arranged along the top of the load-bearing column 1 through the connecting groove. 4. The crossbeam 4 is arranged vertically to the load-bearing column 1, and the clean room is erected on the crossbeam 4 with water pipes and air pipes.

[0027] The width of the enclosure plate 2 between the two adjacent load-bearing columns 1 is 1 meter. The enclosure 2 is made of glass. The outer wall of the load-bearing column 1 is provided with a limit groove, and the limit groove is matched with the enclosure plate 2 for clamping the enclosure plate 2 . The load-bearing column 1 is made of aluminum alloy, and the bottom surface area of the load-bearing column 1 is 25cm 2 . The bottom plate is the bottom surface of a plastic plate body. The beam 4 is provided...

Embodiment 2

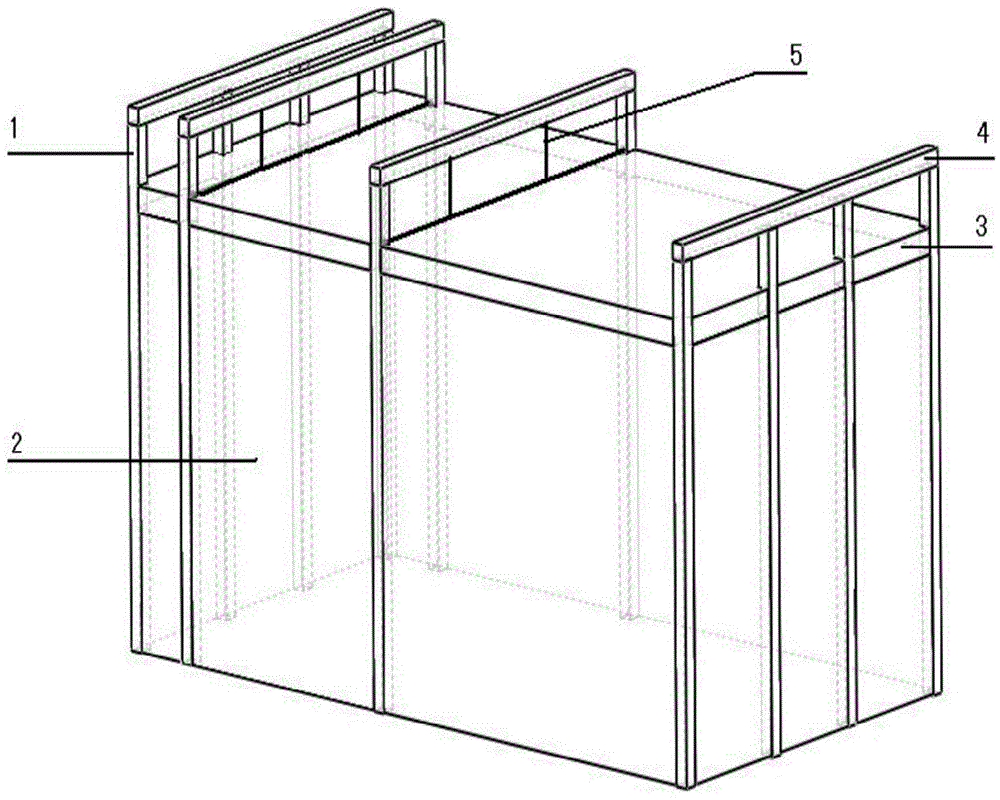

[0029] as attached figure 2 , the height of the load-bearing column 1 is higher than the enclosure plate 2, and the top of the through hole of each load-bearing column 1 is clamped with a connecting groove, and a crossbeam 4 is arranged along the top of the load-bearing column 1 through the connecting groove, The crossbeam 4 is vertically arranged with the load-bearing column 1, and the clean room is erected on the crossbeam 4 with a water pipe and an air pipe; It plays the role of hanging the connectors arranged between the splicing units of the top plate.

[0030] The width of the enclosure plate 2 between the two adjacent load-bearing columns 1 is 3 meters. The enclosure 2 is made of glass. The outer wall of the load-bearing column 1 is provided with a limit groove, and the limit groove is matched with the enclosure plate 2 for clamping the enclosure plate 2 . The load-bearing column 1 is made of aluminum alloy, and the bottom surface area of the load-bearing column 1...

Embodiment 3

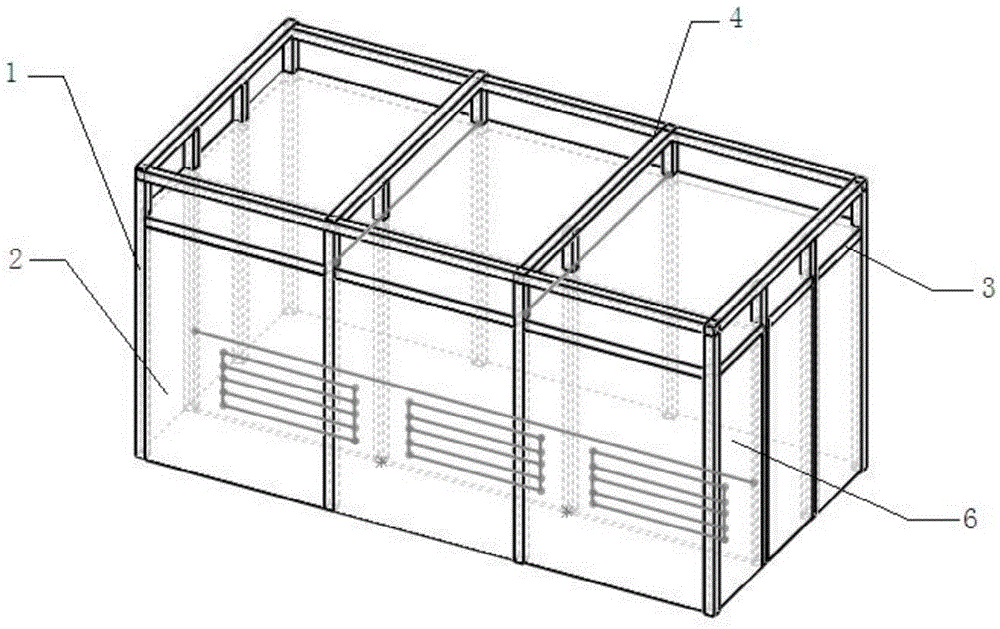

[0032] as attached Figure 3a , 3b , 3c, in the clean room, a ventilating partition is built with spaced enclosures 2 and load-bearing columns 1, through the ventilating partition, the side wall, between the side wall and the ventilating partition The top plate and the bottom plate in between form a closed ventilation interlayer 6, the lower part of the ventilation partition is provided with ventilation holes, matching with the ventilation holes, shutters are arranged at the ventilation holes, and the air flow is from the shutters through the clean The room enters the ventilation interlayer 6 and flows out from the air outlet on the top plate of the ventilation interlayer 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com