Automatic wire arranging system

A line management and automatic technology, applied in the direction of lines/collector components, electrical components, circuits, etc., can solve problems such as inapplicability, and achieve the effects of easy production, improved work efficiency, and safe transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

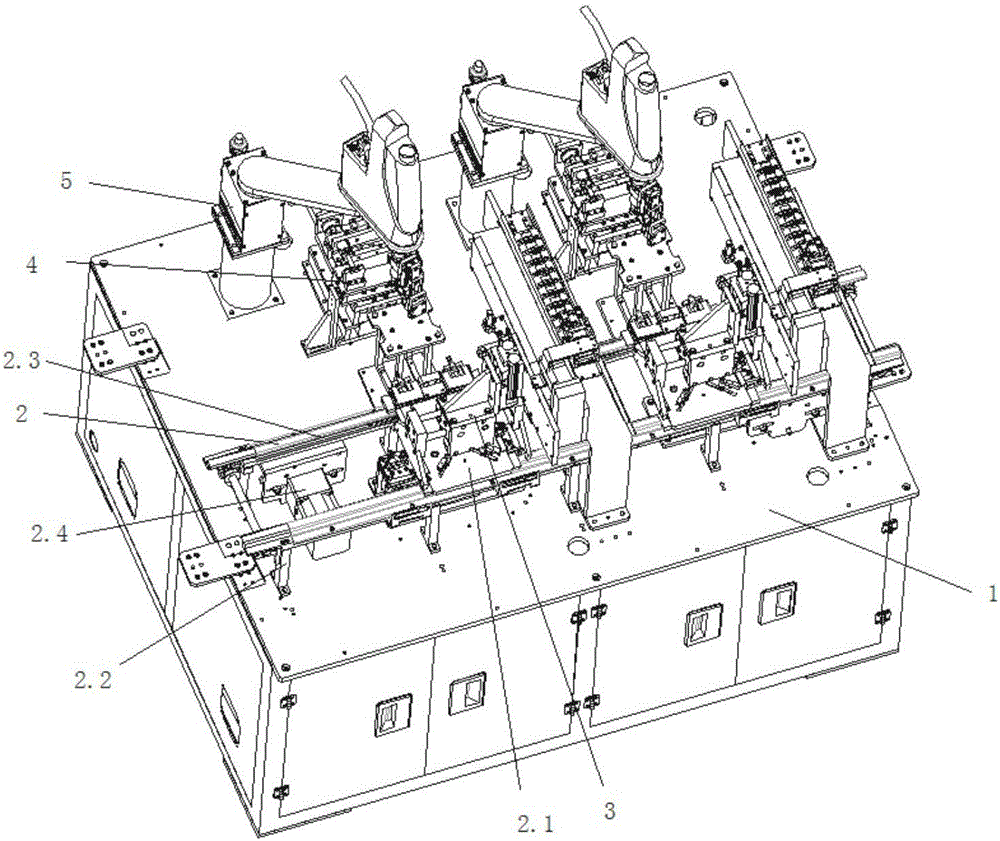

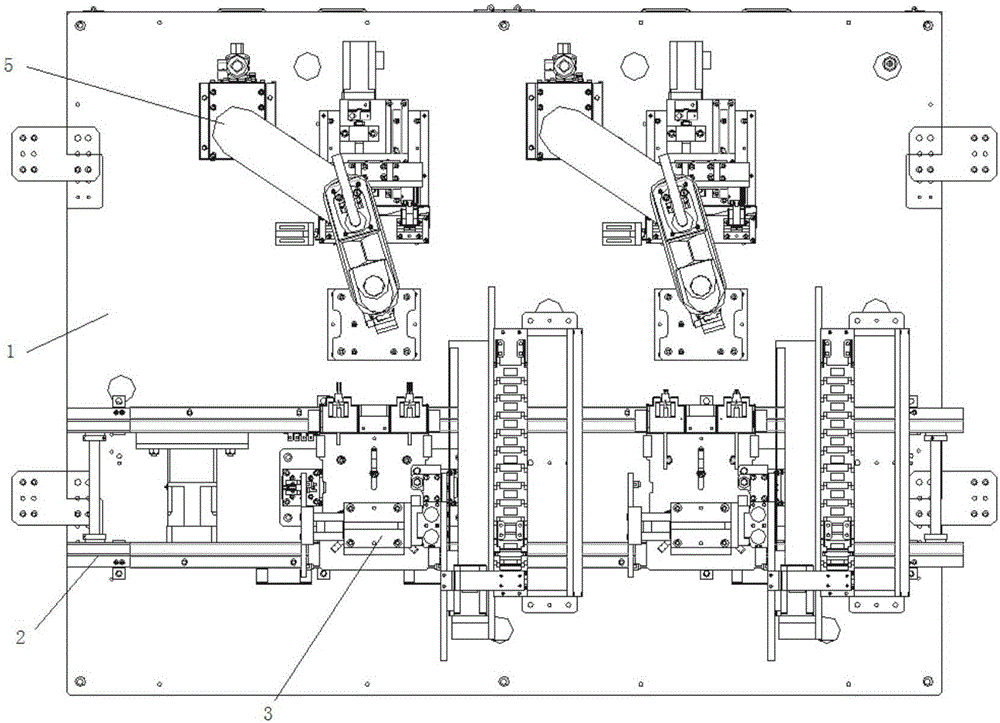

[0050] See figure 1 with figure 2 , An automatic cable management system, including a work surface 1, two sets of line management work groups arranged on the work surface 1 and arranged side by side, and a controller connected to the two sets of the line management work groups at the same time, the controller adopts The PLC controller is installed inside the counter with the work surface 1.

[0051] The wire management working group includes a conveying device 2, a lifting and shifting module 3, an insulating layer removal module 4, and a wire management and cutting module 5. The details are as follows:

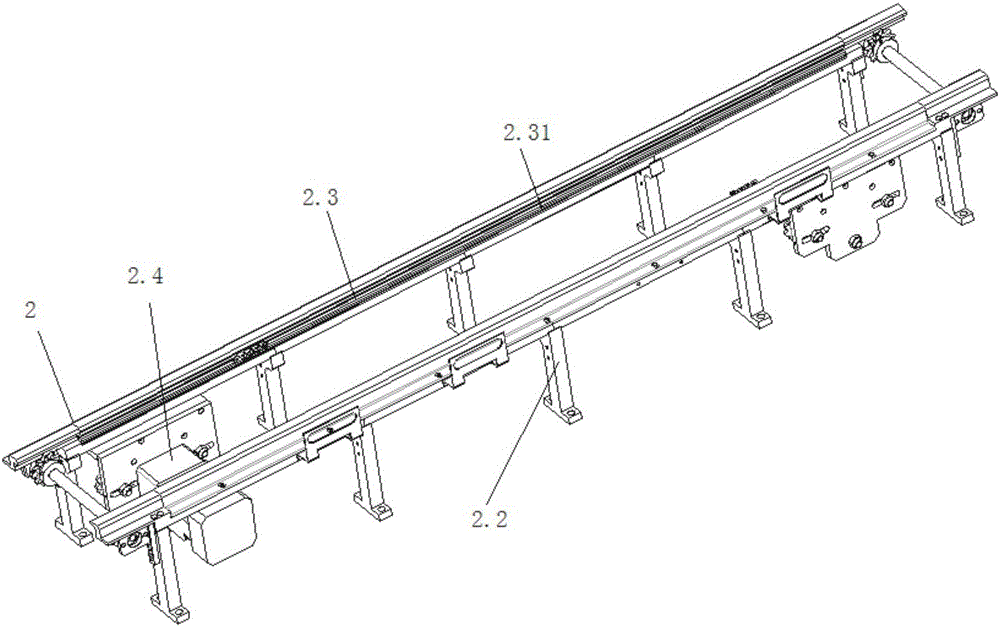

[0052] The conveying device 2 is detailed in figure 1 with image 3 , Specifically including a jig 2.1 for fixing the wire, a support frame 2.2 for supporting, and a chain group 2.3 set on the support frame 2.2 and used to transport the jig 2.1 to the station to be lifted. The chain The group 2.3 includes two chains 2.31 (the motors 2.4 that control the actions of the chains are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com