Preparation method of metal hollow sphere composite with grid-reinforced structure

A technology for metal hollow spheres and reinforced structures, which is applied in the field of preparation of metal hollow sphere composite materials, can solve the problems of difficulty in realizing performance design and regulation, and achieve the effects of realizing performance designability, improving strength, and improving energy absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

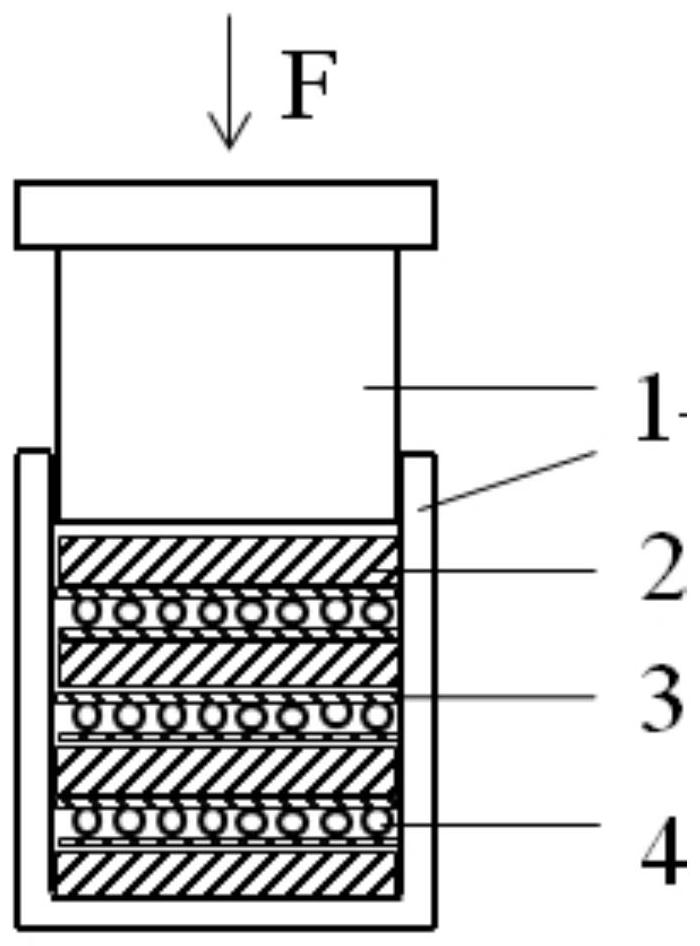

[0030] The technical scheme adopted in the present invention is: a method for preparing a metal hollow sphere composite material with a grid-reinforced structure, and the specific method includes the following steps:

[0031] Step 1: Carry out structural design on the prepared metal hollow sphere composite material, and complete material preparation before extrusion casting. A layer of metal hollow spheres is bonded between two layers of mesh reinforced structures to form an arrangement structure unit. A certain thickness of matrix material is placed between the structural units and on the contact surface with the upper and lower sides of the mold. The base material and structural units are put into the casting mold according to the designed sequence and number, and the preparation of the material before extrusion casting is completed.

[0032] Step 2: Squeeze casting is used to realize the forming of the material. The mold is heated in a resistance furnace. During the heati...

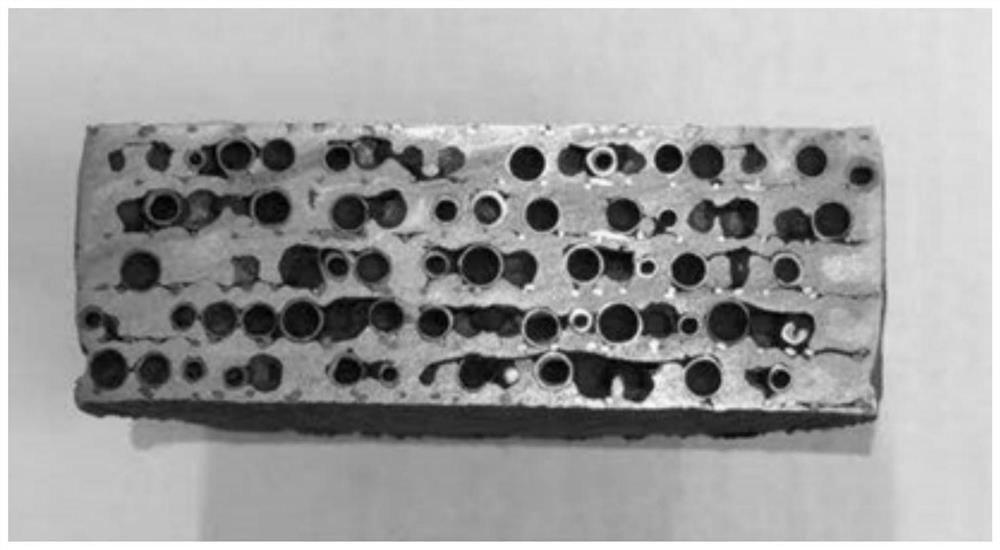

Embodiment 1

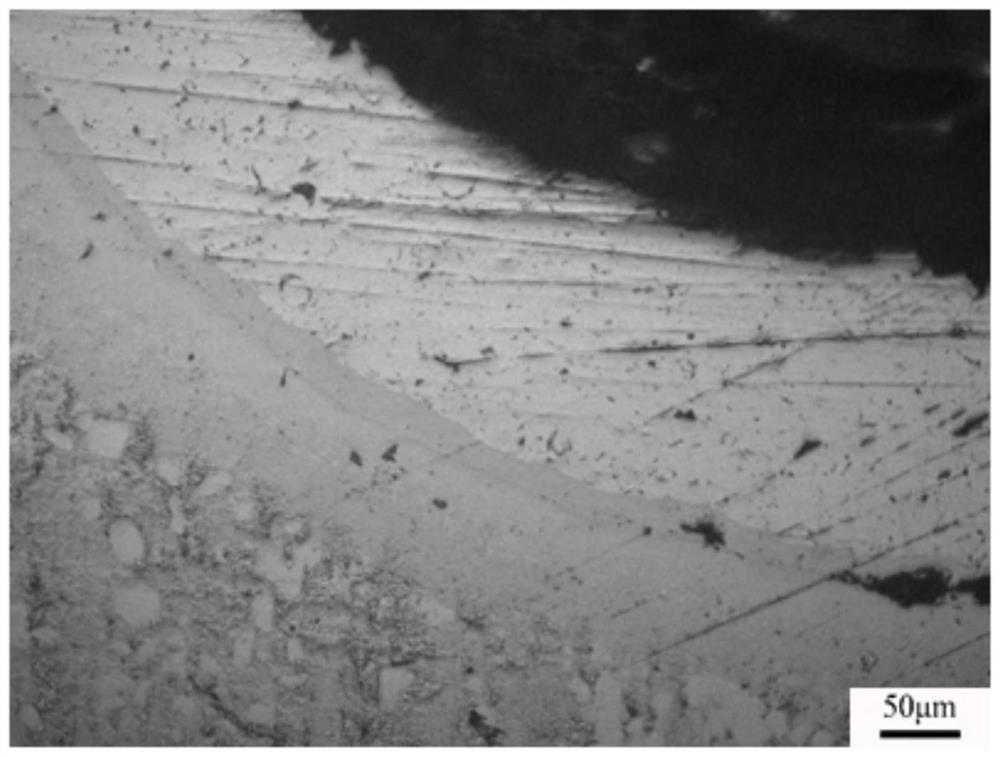

[0046] Step 1. Design the metal hollow sphere composite material is composed of 5 arrangement structural units and 6 A356 substrates with a size of Φ49mm×5mm. The grid structure material is 316L stainless steel alloy, the diameter of the alloy wire is 240μm, and the raw material of the metal hollow sphere is 316L stainless steel Alloy, the outer diameter of which is 3 mm, is arranged most densely on the grid plane. Cut the A356 substrate and 316L grid structure, the size is Φ50mm×5mm, and polish the oxide film on the surface. The 316L grid was soaked in 3% polyvinyl alcohol aqueous solution, and then the hollow spheres were fixed between the two-layer grid structure, and 5 structural units were fixed. According to the sequence of base body, structural unit, base body, etc., they are stacked in a mold with an inner diameter of Φ50mm, and the molds are closed.

[0047] Step 2: Place the mold in a resistance furnace, heat it up to 710°C at a heating rate of 10°C / min, keep it war...

Embodiment 2

[0051]Step 1. Designing the composite material is composed of 5 arrangement structural units and 6 industrial pure aluminum substrates with a size of Φ49mm×5mm. The grid structure material is NiTi shape memory alloy, the diameter of the alloy wire is 200μm, and the hollow sphere material is TC4 alloy. Its outer diameter is 3mm, and it is the most densely arranged on the grid plane. Cut the industrial pure aluminum substrate and NiTi grid structure, the size is Φ50mm × 5mm, and polish the oxide film on the surface. The 304 grid was soaked in a 3% polyvinyl alcohol aqueous solution, and then TC4 hollow spheres were fixed between two layers of grid structures to fix 5 structural units. According to the sequence of base body, structural unit, base body, etc., they are stacked in a mold with an inner diameter of Φ50mm, and the molds are closed.

[0052] Step 2: Place the mold in a resistance furnace, heat it up to 650°C at a rate of 10°C / min, keep it warm for 60min, and apply a fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com