Conductive core plate and manufacturing method

A manufacturing method and conductive core technology, which can be applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems that battery arrays are difficult to realize, it is impossible to add 2 rows of batteries experimentally, and the development and implementation of high-efficiency components are limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

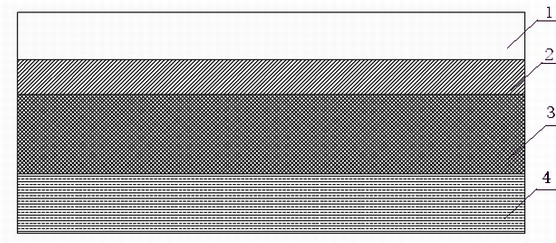

[0035] The present invention is a conductive core board, the conductive core board is an insulating material layer 1, a metal conductive circuit layer 2, an encapsulating adhesive film layer 3, and a backplane layer 4 from top to bottom, and the layers are heated at low temperature bonding;

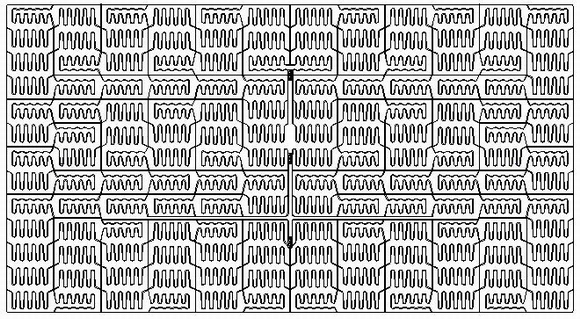

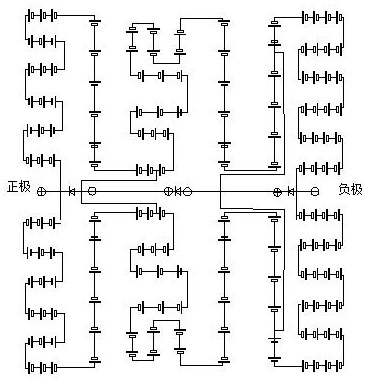

[0036] The metal conductive circuit layer 2 and the encapsulation adhesive film layer 3 are compositely bonded, and a conductive circuit pattern is arranged on the metal conductive circuit layer 2; a number of small holes are arranged on the insulating material layer 1, and the positions of the holes are in line with the The positions of the electrode points on the battery sheet correspond; the conductive circuit diagram is based on the set unit pattern, and the unit pattern is arranged in an array above the battery sheet.

[0037] Further, the unit pattern is that the circuit unit adopts the form of a bell mouth unit and the positive and negative electrodes 6 are opened and divided.

[...

Embodiment 2

[0047] The present invention also provides a method for manufacturing the above-mentioned conductive core board, the method comprising the following steps:

[0048] Copper foil or copper-aluminum foil is used to make metal conductive circuit layer 2, and copper foil or copper-aluminum foil of the same width is combined with packaging film layer 3, and a solid-state laser is used for scribing. Etching specific conductive circuit patterns on copper and aluminum foil;

[0049] Remove the etched copper foil or copper-aluminum foil to form specific conductive channels and insulating channels, that is, conductive circuit diagrams;

[0050] Then punch a number of small holes on the insulating material layer 1, the positions of the holes correspond to the positions of the electrode points on the battery sheet, and isolate the path between the battery sheet and the conductive core board;

[0051] Stack the prepared insulating material layer 1, metal conductive circuit layer 2, encapsu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com