Novel solidifying machine

A curing machine, a new type of technology, used in printing machines, general parts of printing machinery, printing and other directions, can solve the problems of insufficient light source conversion, dark font lighting effect, low light transmittance, etc., to achieve production cost and tail end. High material waste, bright and uniform luminous effect, strong weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now the present invention is further described in conjunction with description of drawings and embodiments:

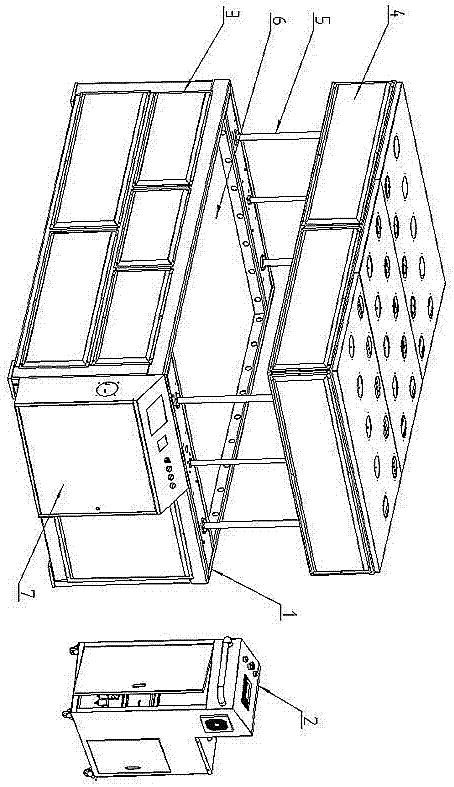

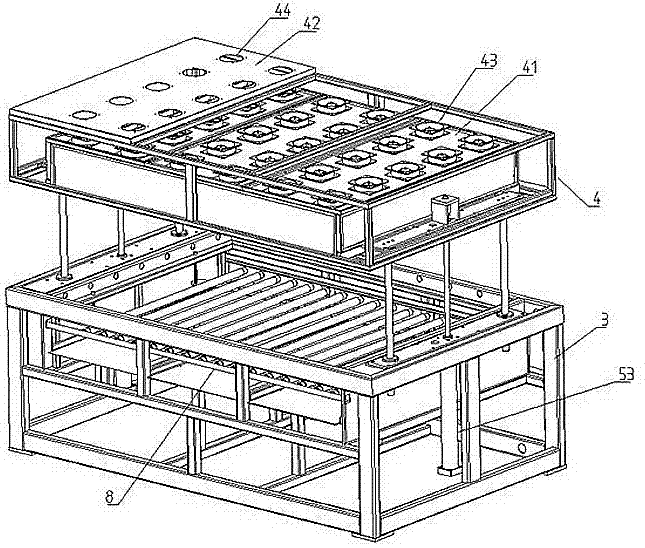

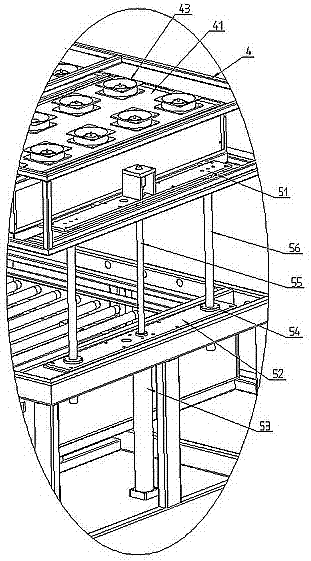

[0020] refer to figure 1 and figure 2 , a new type of curing machine, including a main base 1 and a main electrical cabinet 2 of the curing machine, wherein: the main base 1 includes a main bed 3 and an upper frame 4, and sliding guides are provided on both sides of the main bed 3 The rod group 5, the sliding guide rod group 5 is connected to the main bed 3 and the upper frame 4, and the main bed 3 is also provided with a horizontally fixed toughened glass platform 6, and the toughened glass platform 6 is used to place the fonts, The bottom of the tempered glass platform 6 is provided with an ultraviolet lamp array 8, the upper frame 4 is provided with a lining top plate 41 and an outer top plate 42, and the inner lining top plate 41 is provided with a heat dissipation fan array 43, and the outer top plate 42 is used for heat dissipation. Corresponding throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com