A two-dimensional photocatalytic fluidized bed device

A fluidized bed, photocatalytic technology, applied in chemical/physical/physical chemical processes, chemical/physical/physical chemical processes of energy application, chemical instruments and methods, etc., can solve the problem of small batch processing capacity and low light utilization rate , Fluidized bed thickness and other issues, to achieve the effect of reducing light loss, enhancing light guiding, and uniform light-receiving surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

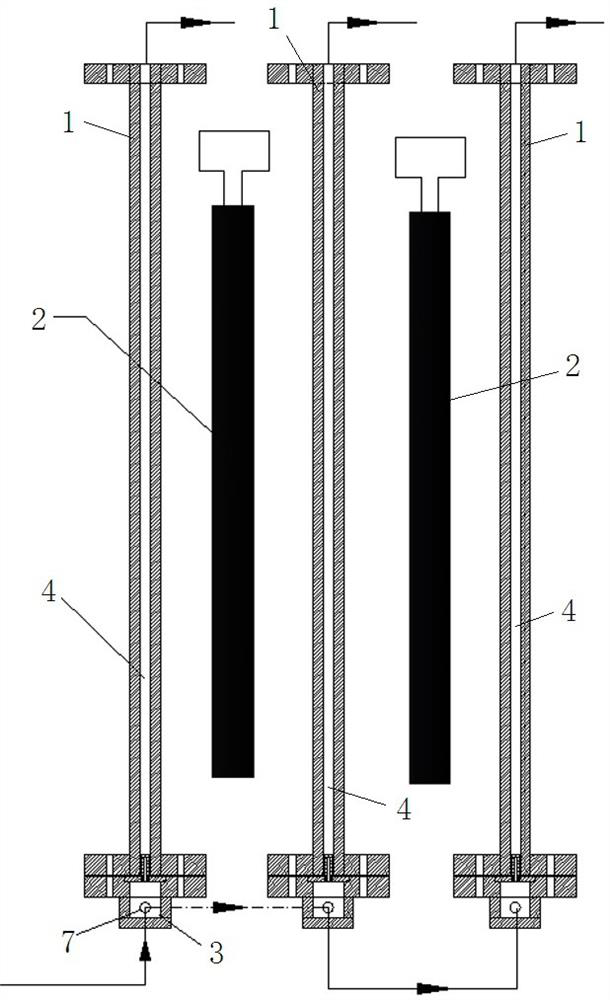

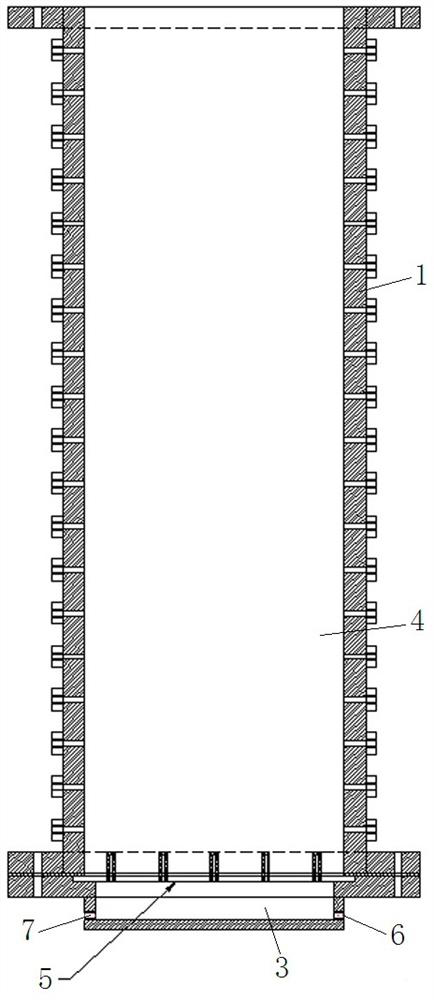

[0020] Such as Figure 1~2 As shown, a two-dimensional photocatalytic fluidized bed device of the present invention includes several two-dimensional fluidized beds 1 distributed side by side and made of transparent materials. The two-dimensional fluidized bed is placed vertically, and the two-dimensional flow The reaction zone 4 of the fluidized bed 1 is filled with a light guide, and a light source 2 is arranged between two adjacent two-dimensional fluidized beds 1 . The two-dimensional fluidized bed has the advantage of thin walls, which is beneficial to the intake of light and reduces light loss, and the light guide can be greatly enhanced by filling the reaction zone of the two-dimensional fluidized bed with light guides.

[0021] In this embodiment, the bottom end of the two-dimensional fluidized bed 1 is provided with a gas buf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com