Suspension microorganism carrier and its preparation method

A carrier, microporous technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the difficulty of increasing production and labor intensity, difficult to precisely control pore distribution and structure, and manufacture raw materials The problem of high cost, to achieve the effect of low suspension fluidity and manufacturing cost, excellent microbial affinity, and reduced cost of manufacturing raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 100 g of polyvinyl alcohol with a degree of polymerization of 1799 was added to 750 ml of water under stirring, and the temperature was gradually raised to 90° C. until the polyvinyl alcohol was completely dissolved.

[0026] When the temperature of the polyvinyl alcohol solution dropped to 50°C, slowly add 180ml of 40% sulfuric acid, the temperature of the system would rise at this time, and when the temperature dropped to 50°C, add 100ml of formalin for acetalization. After 10 minutes, 15 g of sepiolite powder was added, and the mixture was rapidly stirred to disperse evenly in the solution phase. Then, pour the material mixture into the acid-resistant plastic mold, pass preheated air from the bottom of the mold through the microporous glass gas distributor to increase the volume to 5000ml, stop the ventilation, seal the mold and place it at a temperature of 50°C Process for 6 hours. Finally, open the mold, take out the gray foam, wash off the residual sulfuric acid ...

Embodiment 2

[0029] 100 g of polyvinyl alcohol with a degree of polymerization of 1799 was added to 900 ml of water under stirring, and the temperature was gradually raised to 90° C. until the polyvinyl alcohol was completely dissolved.

[0030] When the temperature of the polyvinyl alcohol solution drops to 30°C, slowly add 160ml of 40% sulfuric acid, and the system temperature will rise at this time. When the temperature drops to 30°C, add 80ml of formaldehyde solution for acetalization. After 15 minutes, 20 g of powdered activated carbon was added and stirred rapidly to make it evenly dispersed in the solution phase. Then, pour the material mixture into an acid-resistant plastic mold, pass preheated air from the bottom of the mold through a microporous glass gas distributor to increase the volume to 7600ml, stop the ventilation, seal the mold and place it at a temperature of 40°C Process 20 hours. Finally, open the mold, take out the formed black foam, wash off the residual sulfuric ac...

Embodiment 3

[0034] According to the same method of embodiment 2, the addition amount of activated carbon is changed to 40g, and other compositions and operation methods remain unchanged. The mass fraction of the obtained foam loaded with activated carbon is 28%, its appearance and pore structure are consistent with those of Example 2, the pore diameter is between 0.5 and 2 mm, and the bulk density is about 18Kg / m 3 .

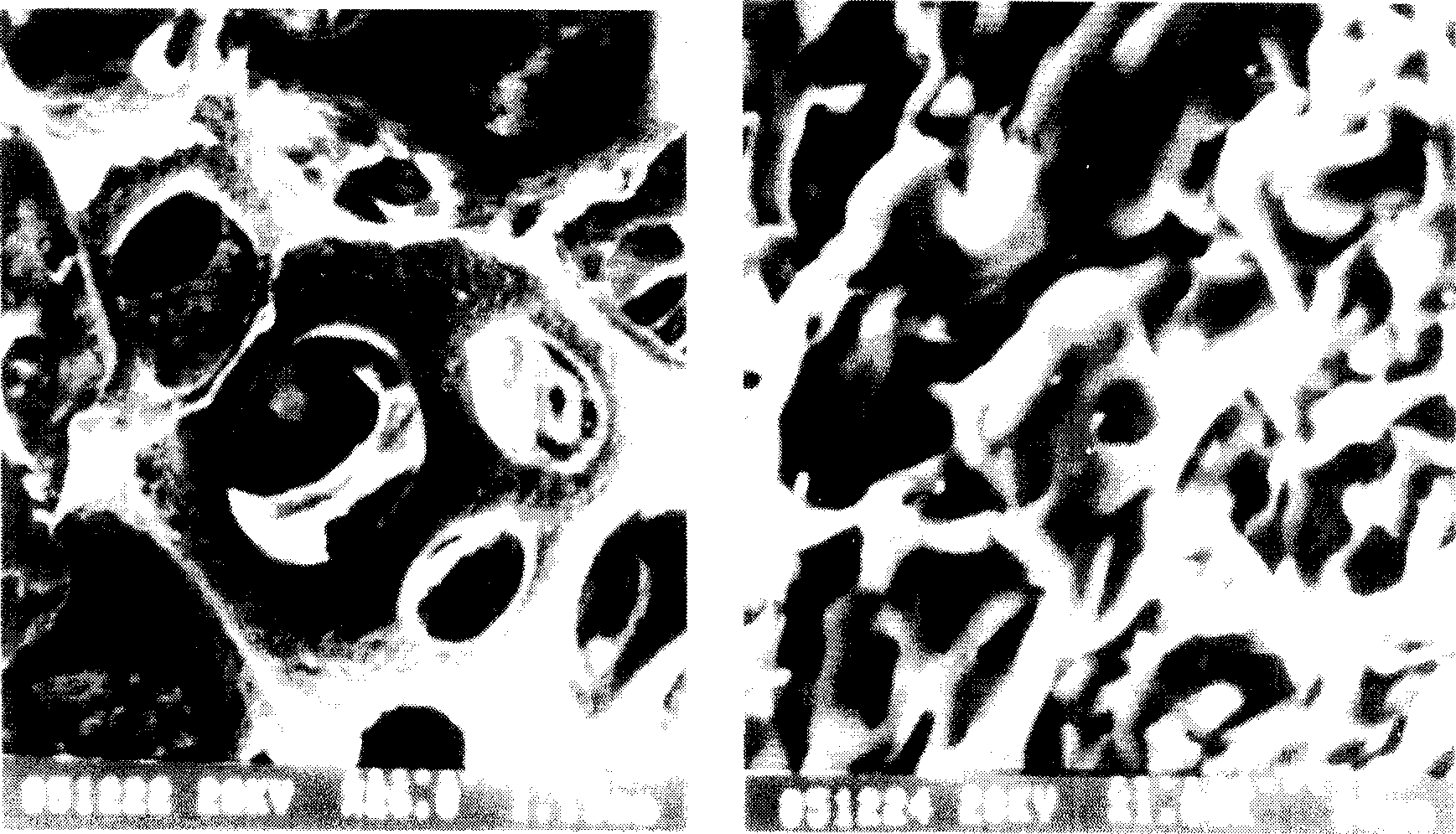

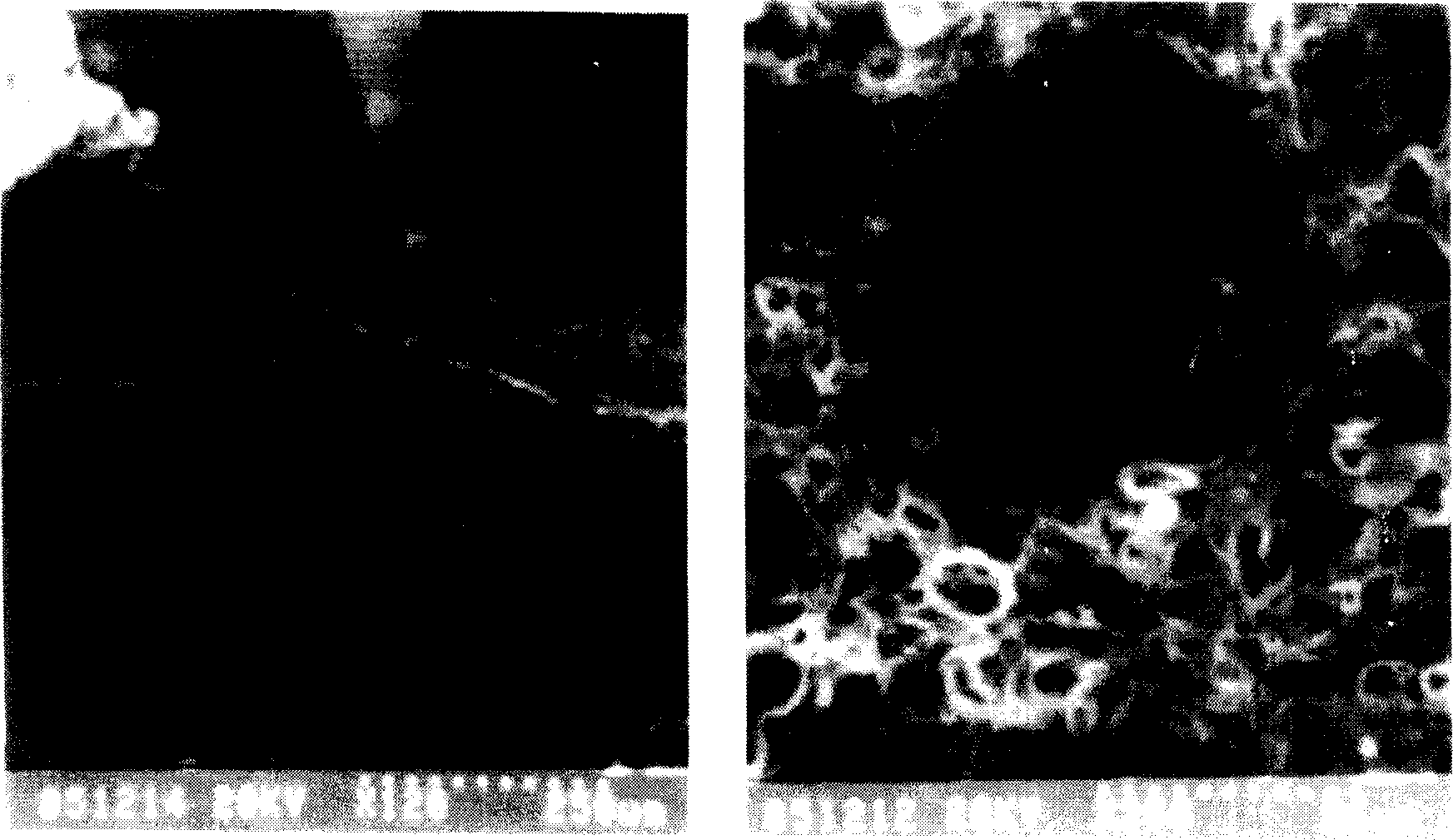

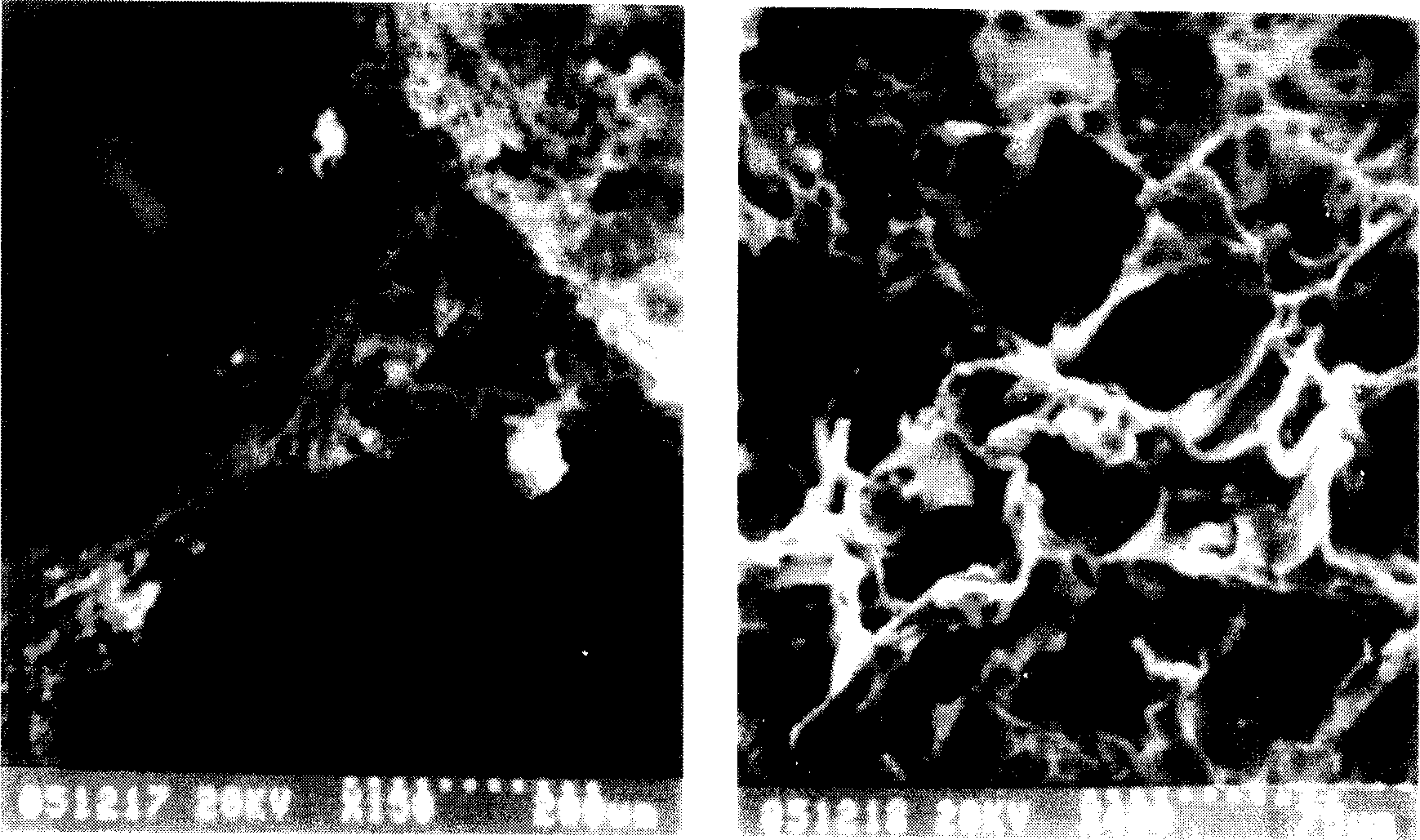

[0035] SEM photographs of the material are shown in image 3 It can be shown that the pore size of its framework micropores is larger than that of the sample obtained in Example 2, most of which are below 60 μm, and its pores are more developed, with a specific surface area of 69 m. 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com