Photoconductive coating film of diffraction grating and manufacture method thereof

A technology of diffraction grating and manufacturing method, which is applied in the direction of light guide, optical waveguide coupling, optics, etc., can solve the problems of limited range of outgoing light intensity and low utilization rate of light energy, and improve the uniformity of light guide, improve the uniformity and Field of view, easily embossed and reproduced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

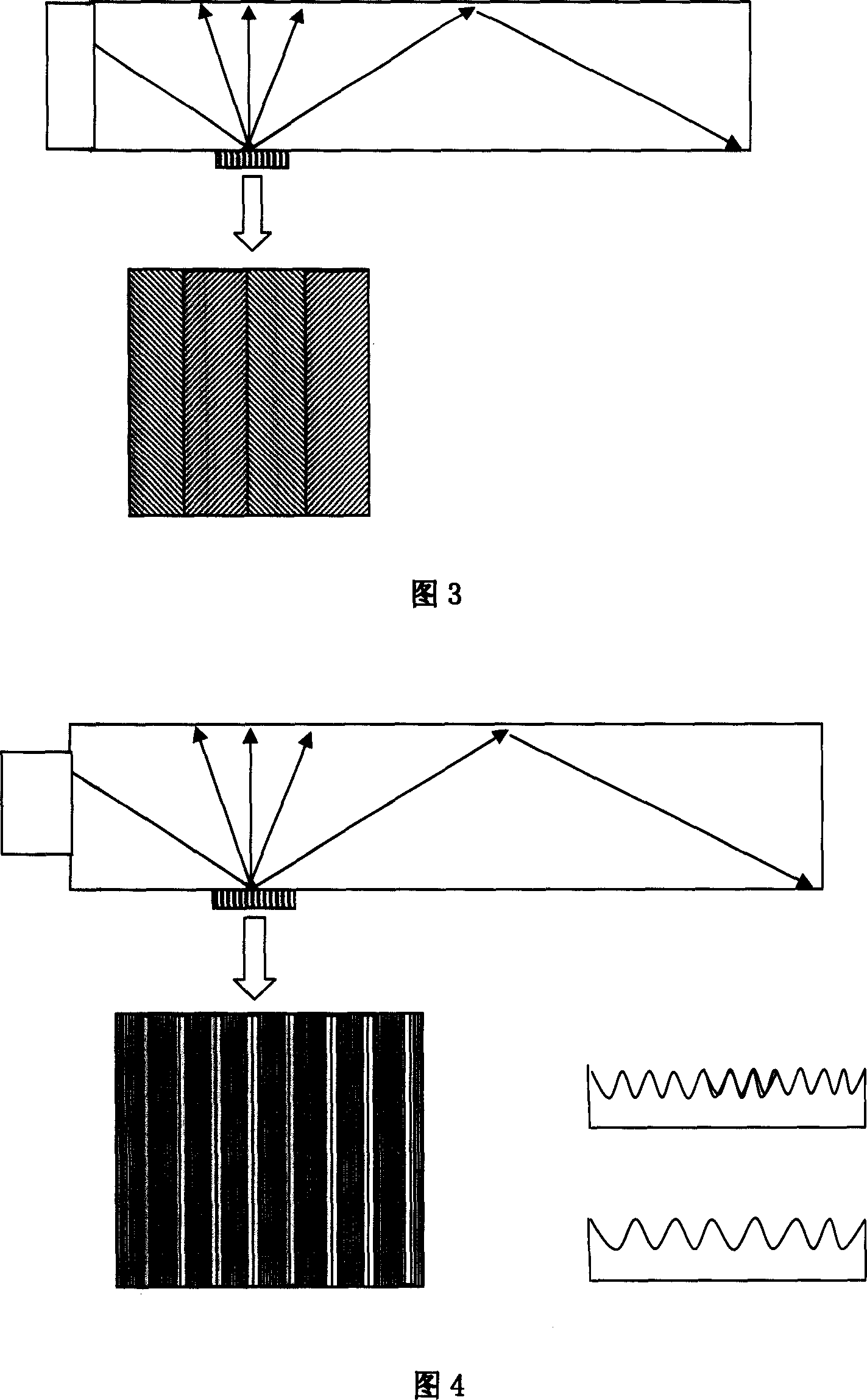

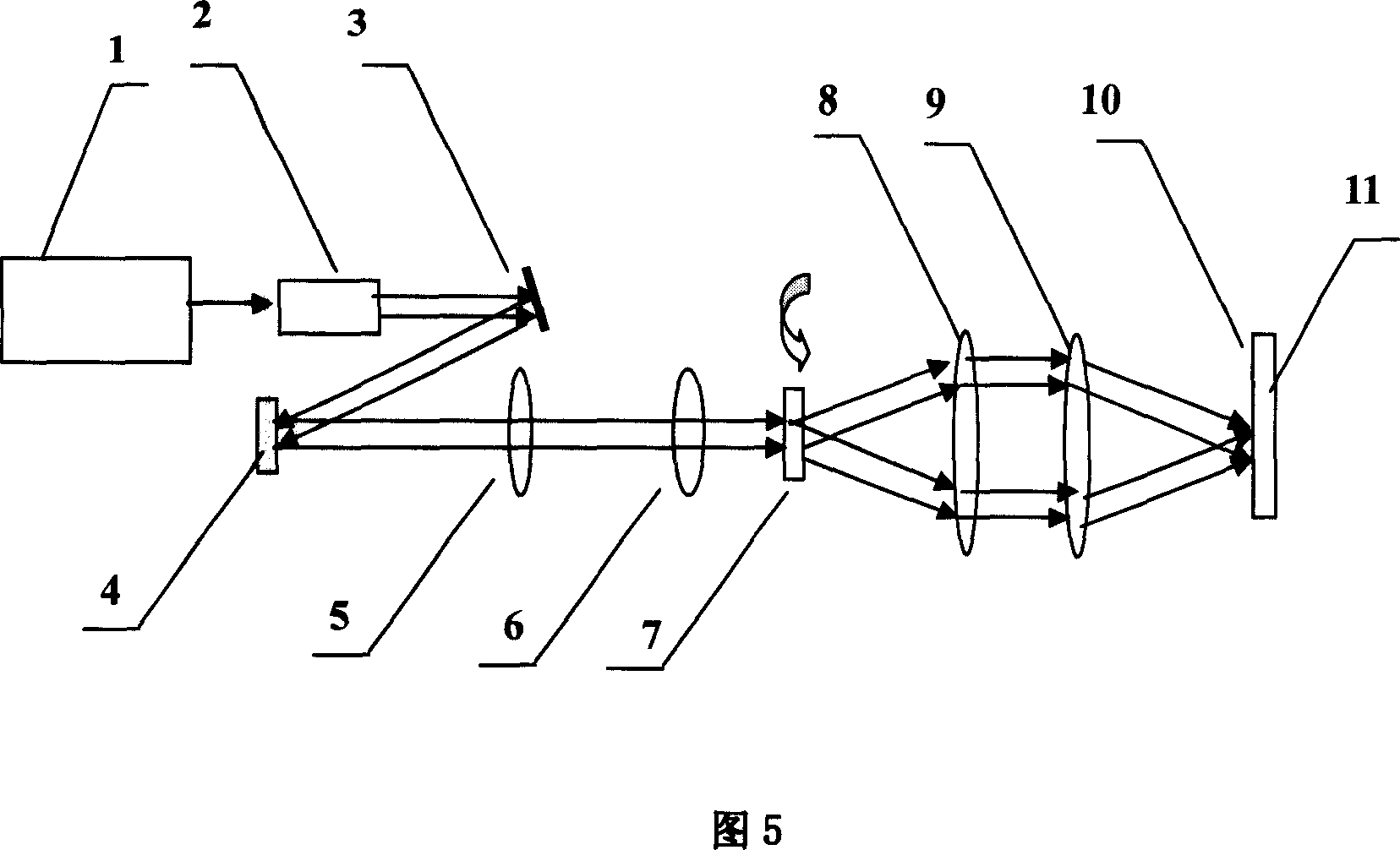

[0040] Embodiment 1: Referring to accompanying drawings 1 to 5, a method for making a light guide pattern on a film by using a digital interference lithography system and a molding system to prepare a diffraction grating light guide film includes the following steps:

[0041] (1) According to the uniformity requirements of the light guide, the diffraction structure distribution of the light guide pattern is designed, and the direction of the light guide is determined by the grating equation and the law of refraction; The intensity is determined by the orientation and area ratio of the diffraction grating in the light guide pattern;

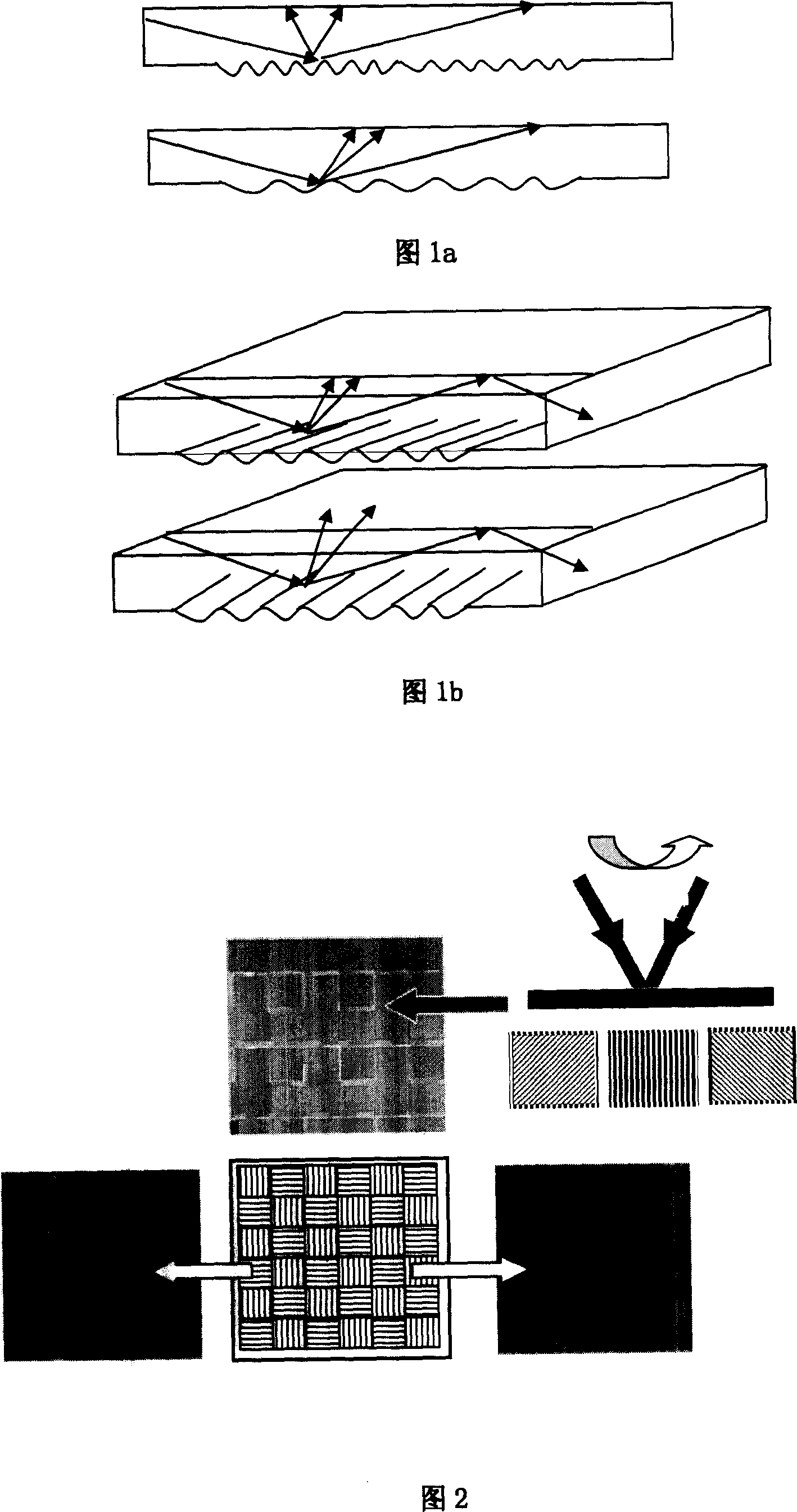

[0042] The plane formed by the diffracted light and the incident light is always perpendicular to the grating lines. Therefore, rotating the orientation of the grating can change the spatial azimuth of the diffracted light. perspective. See accompanying drawings 1a and 1b.

[0043] The higher the spatial frequency of the grating, the larger the ...

Embodiment 2

[0050] Embodiment 2: A method for improving the uniformity of a diffraction grating light guide film, comprising the following steps:

[0051] (1) According to the uniformity requirements of the light guide, the distribution of the diffraction grating structure of the light guide pattern is designed, and the direction of the light guide is determined by the grating equation and the law of refraction; The intensity is determined by the orientation of the diffraction grating in the light guide pattern and the proportion of the area occupied by different structured gratings; in order to obtain the uniformity of light guide, a digital micro-mirrordevice (DMD) is used as the input method to combine the pixels of the diffraction grating , the light guide patterns of different light guide structures are obtained,

[0052] (2) Arranging the light guide patterns generated in step (1) into different sequences according to the pixel structure distribution, corresponding to different diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com