LCM backlight source

A backlight and backlight technology, which is applied in the field of LCM backlight, can solve the problems of complex driver IC and FPC circuit board structure, affecting the service life of LED lamp beads, and the performance degradation of LED backlight, so as to achieve ingenious design of the overall structure, structure Stable, reasonable structure and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

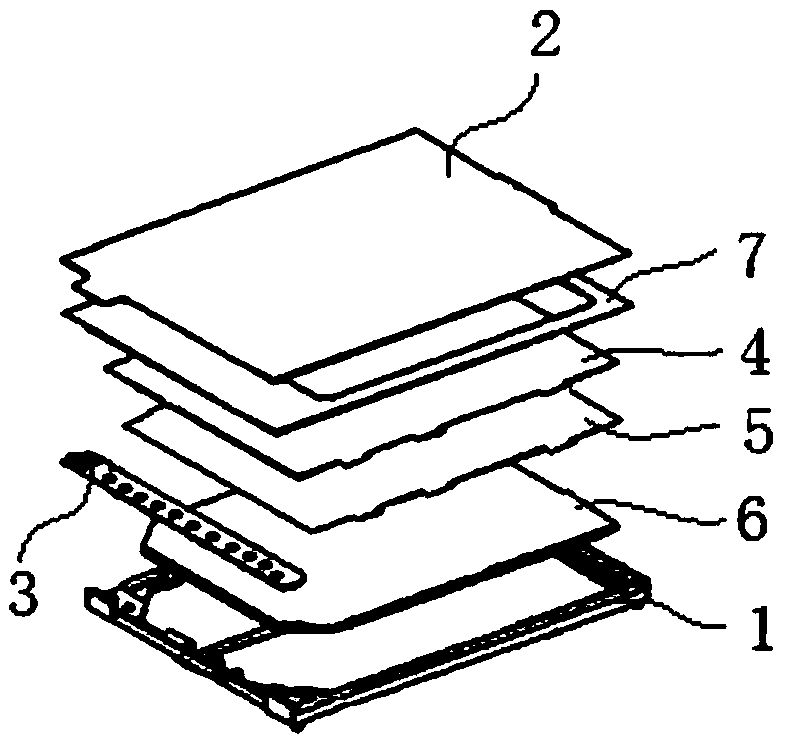

[0014] like figure 1 As shown, an LCM backlight source includes an aluminum alloy protection frame 1, a light-transmitting glass protection plate 2, an LED backlight FPC3, a light guide plate 6, a diffusion plate 4, a diffusion enhancement plate 5, and a light-shielding plastic frame 7. The light-transmitting glass The protection plate 2, the diffusion plate 4, the diffusion enhancement plate 5, and the light guide plate 6 are closely attached together from top to bottom, the light guide plate 6 is completely wrapped by the aluminum alloy protective frame 1, and the LED backlight FPC3 is closely attached On the side wall of one end of the light guide plate 6, and fixed on the installation groove at the end of the aluminum alloy protection frame 1, the light-shielding rubber fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com