Heat treatment method of target blank

A heat treatment method and a technology of a heat treatment furnace, which are applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of low accuracy and stability of heat treatment process, slow heating speed, etc., and achieve shortened production cycle, The effect of mass production speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

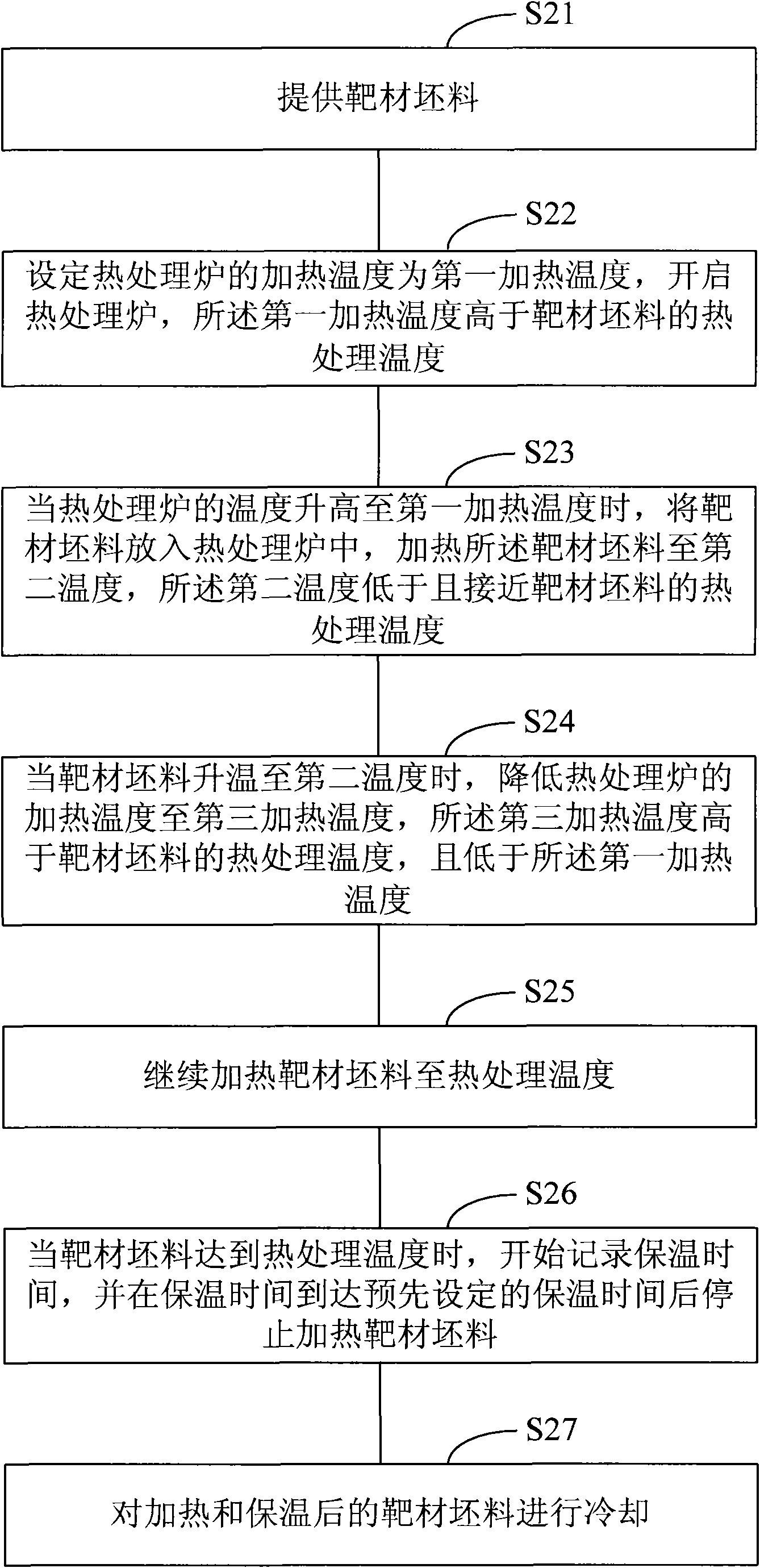

[0025] The heat treatment method of the target blank in the embodiment of the present invention first heats the target blank at a higher heating temperature than the heat treatment temperature, so that the target blank can be heated rapidly, and then when the target blank is about to reach the heat treatment temperature, then The target blank is heated at a lower heating temperature than the heat treatment temperature to reduce the temperature rise rate of the target blank to ensure that it will not exceed the expected heat treatment temperature.

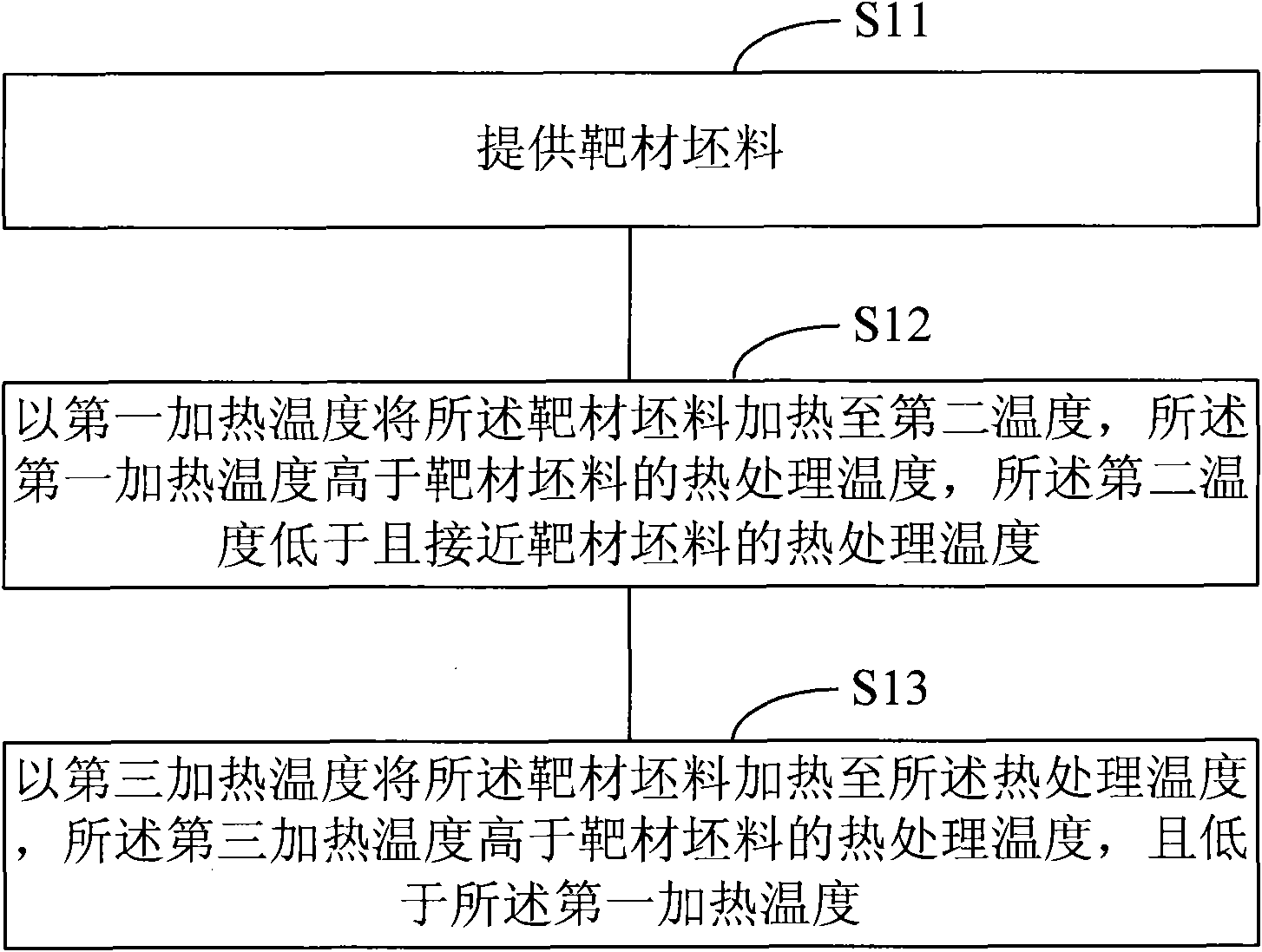

[0026] The heat treatment method of the embodiment of the present invention is as figure 1 shown, including:

[0027] Step S11, providing a target blank;

[0028] Step S12, heating the target blank to a second temperature at a first heating temperature, the first heating temperature is higher than the heat treatment temperature of the target blank, and the second temperature is lower than and close to the heat treatment temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com