Electrochemical aluminum foil suitable for high-temperature and high-speed hot stamping

An anodized aluminum foil, high-speed technology, applied in the field of transfer film, can solve the problems of hot stamping adhesion and edge trimming, poor stability of hot stamping performance, low temperature of anodized aluminum ironing, etc., to achieve improved adhesion , Lower softening temperature, good ironing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

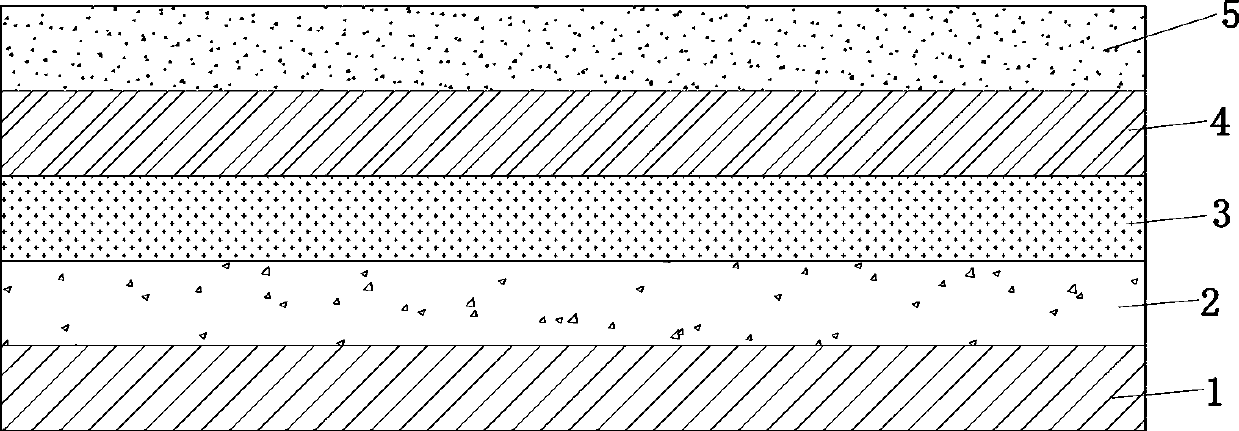

[0016] Figure 1 shows the anodized aluminum foil suitable for high-temperature and high-speed hot stamping without laser effect of the present invention, which includes PET base film 1, release layer 2, imaging layer 3, aluminum-coated layer 4 and adhesive layer 5 from bottom to top. Its preparation method is:

[0017] (1) On the PET base film, a 200-mesh printing roller is used to evenly coat a release layer with a certain release force. The formula of the release layer is emulsified water-based wax: absolute ethanol: deionized water 1:51:48, the wet coating amount is 5.5±0.5g / m 2 , the drying temperature is 140°C;

[0018] (2) On the release layer, use a printing roller with a mesh number of 200 to evenly coat an imaging layer that allows the aluminum plating layer to adhere. The formula of the imaging layer is aminoacrylic resin: methyl ethyl ketone: butyl ester: toner : Alkyd resin (Bangcure PET-308-11)=52.4 : 27 : 19 : 1 : 0.6, dry coating weight is 1.00±0.05 g / m 2 , t...

Embodiment 2

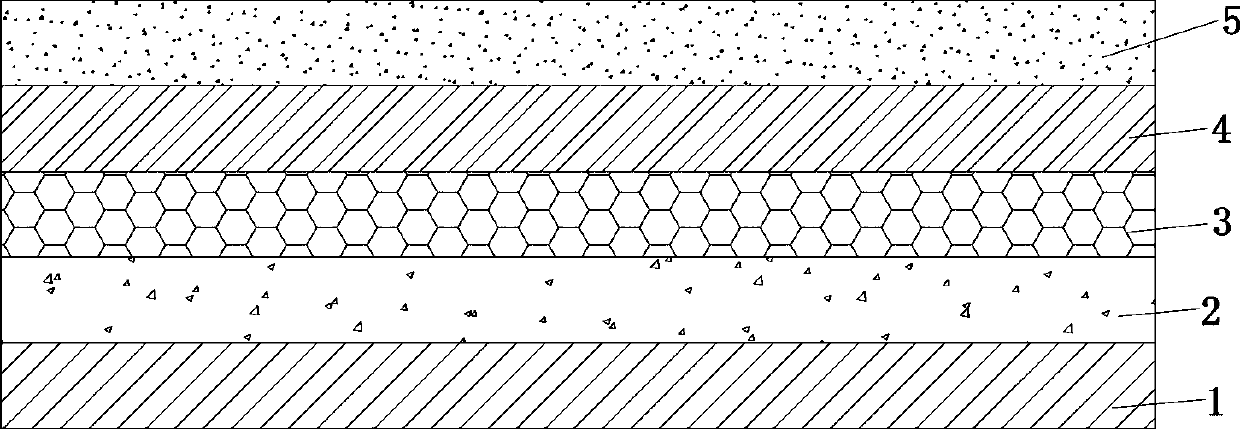

[0022] Figure 2 shows the anodized aluminum foil with laser effect suitable for high-temperature and high-speed hot stamping of the present invention, which includes PET base film 1, release layer 2, imaging layer (with molded patterns) 3, aluminum coating layer 4 from bottom to top And adhesive layer 5, its preparation method is:

[0023] (1) On the PET base film, a 200-mesh printing roller is used to evenly coat a release layer with a certain release force. The formula of the release layer is emulsified water-based wax: absolute ethanol: deionized water 1:50:49, the wet coating amount is 5.5±0.5g / m 2 , the drying temperature is 140°C;

[0024] (2) On the release layer, use a printing roller with a mesh number of 200 to evenly coat an imaging layer that allows the aluminum plating layer to adhere. The formula of the imaging layer is aminoacrylic resin: methyl ethyl ketone: butyl ester: toner : Alkyd resin (Bangcure PET-308-11) = 53: 26.2 : 19 : 1 : 0.8, dry coating weight i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com