Cutting method of textile garment fabric

A technology for textile garments and fabrics, which is applied in the field of textile and garment fabric cutting. It can solve the problems of easy damage of fabrics, low degree of automation, burrs, protrusions and thread ends at cutting ports, etc., so as to facilitate subsequent processing, reduce labor intensity, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

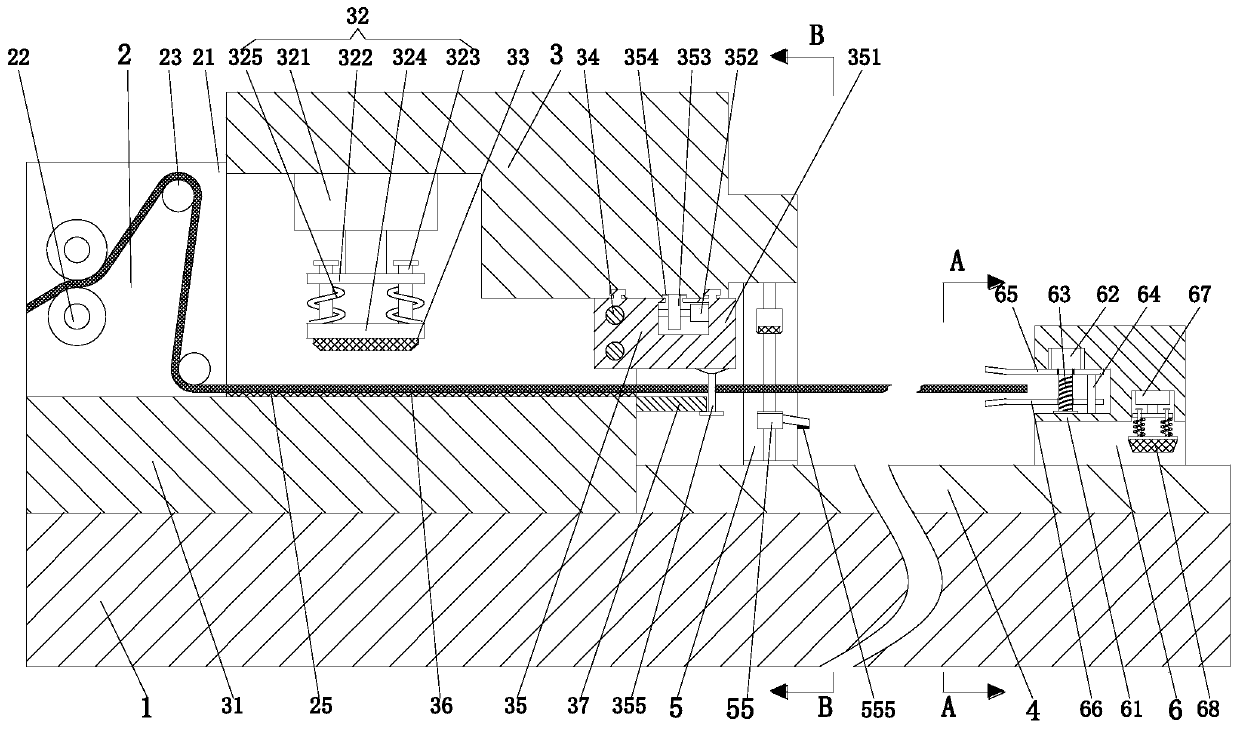

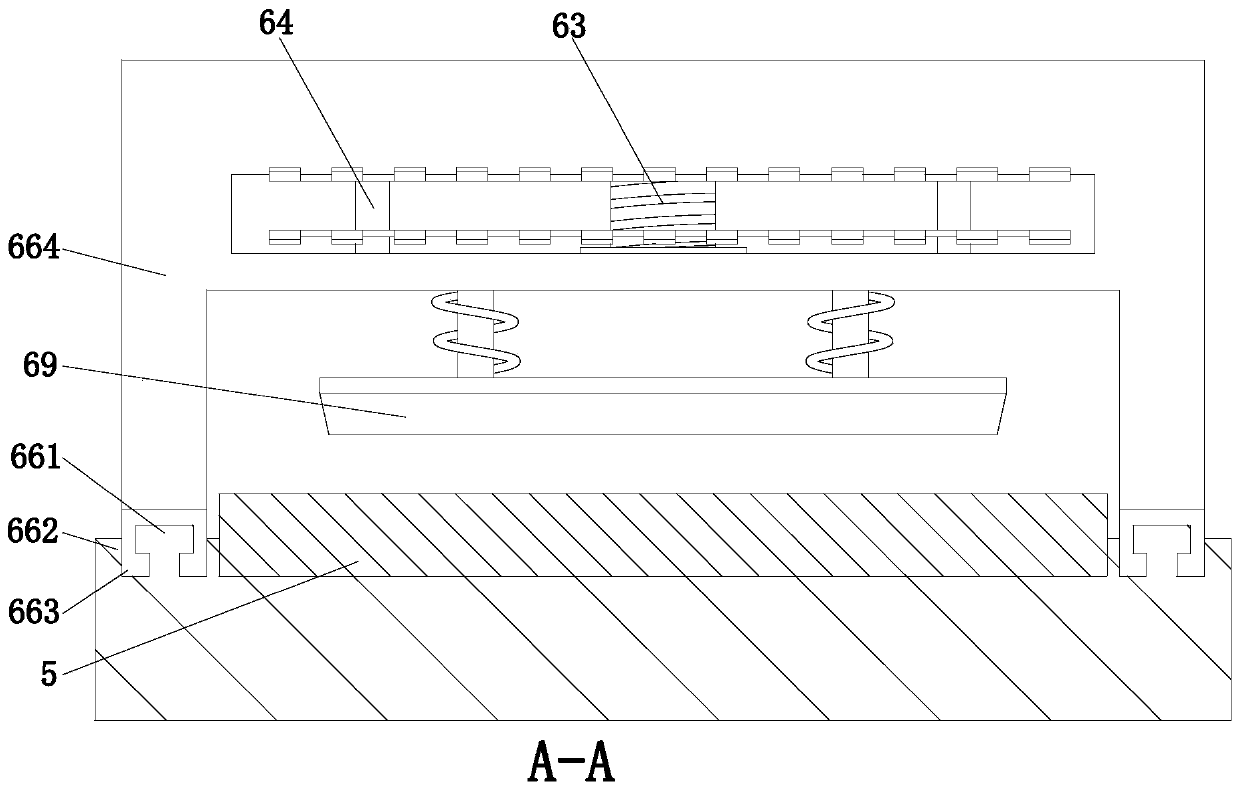

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

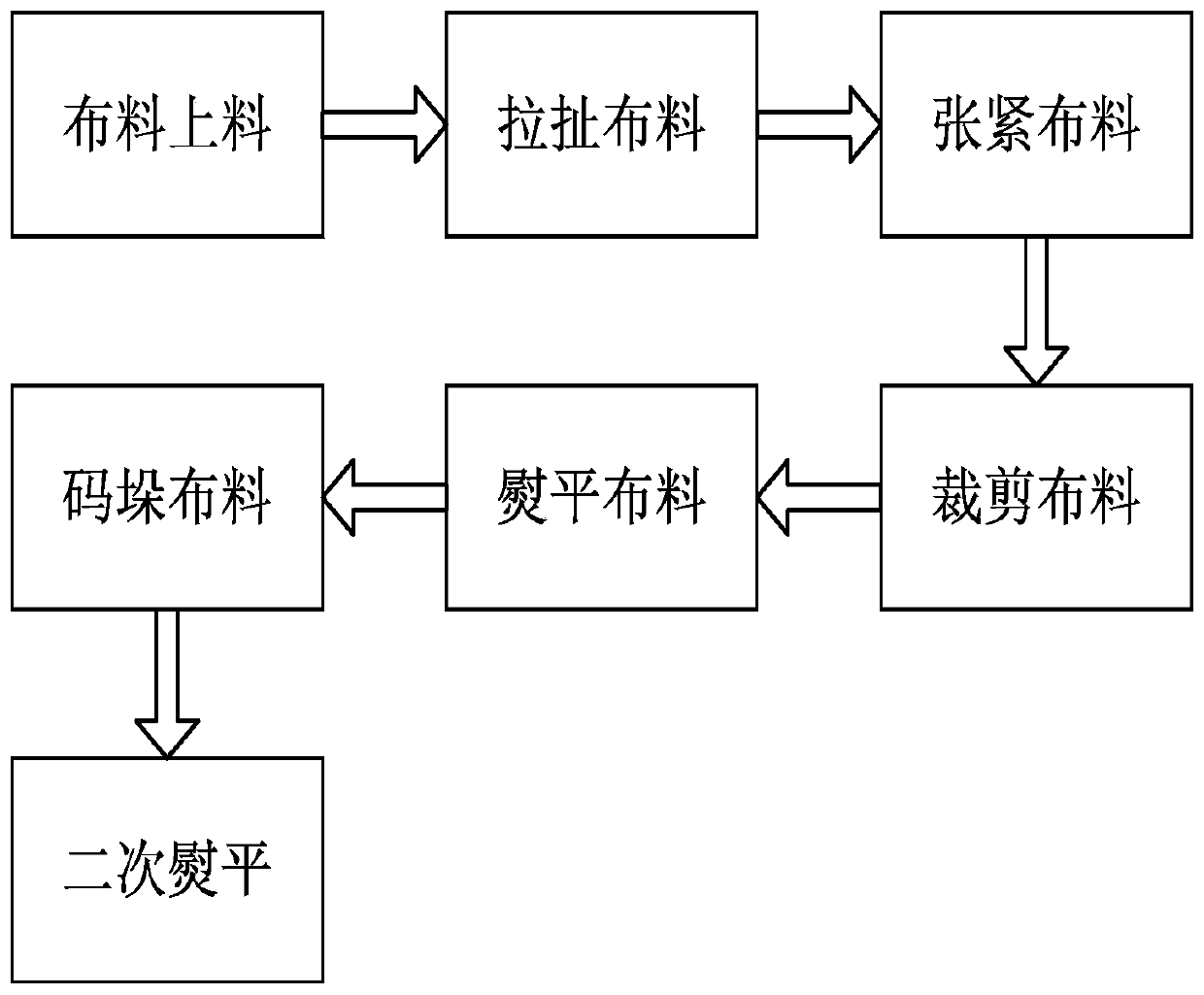

[0033] Such as Figure 1 to Figure 4 Shown, a kind of textile garment cloth cutting method comprises the following steps:

[0034] S1, cloth loading: guide the cloth on the cloth roller to the upper end of the cloth clamping port 37 through the cloth guiding mechanism 2;

[0035] S2. Pulling the cloth: the cloth in step S1 is clamped from the cloth clamping port 37 by the cloth pulling device 6, and the cloth pulling device 6 is moved to a fixed position by the electric slider 613;

[0036] S3. Tensioning of the fabric: fix the left side of the fabric in step S2 through the cloth pressing mechanism 32, and tension the fabric through the cloth pulling device 6;

[0037] S4, cutting the cloth: cutting the cloth stretched in step S3 by the cloth cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com