Multifunctional shirt ironing machine

An ironing machine, a multi-functional technology, applied in washing devices, wrinkle-removing and flattening equipment, textiles and papermaking, etc., can solve the problems of increased production costs, consumption, high capital investment and labor costs, and improve production efficiency , Speed up work efficiency and reduce capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

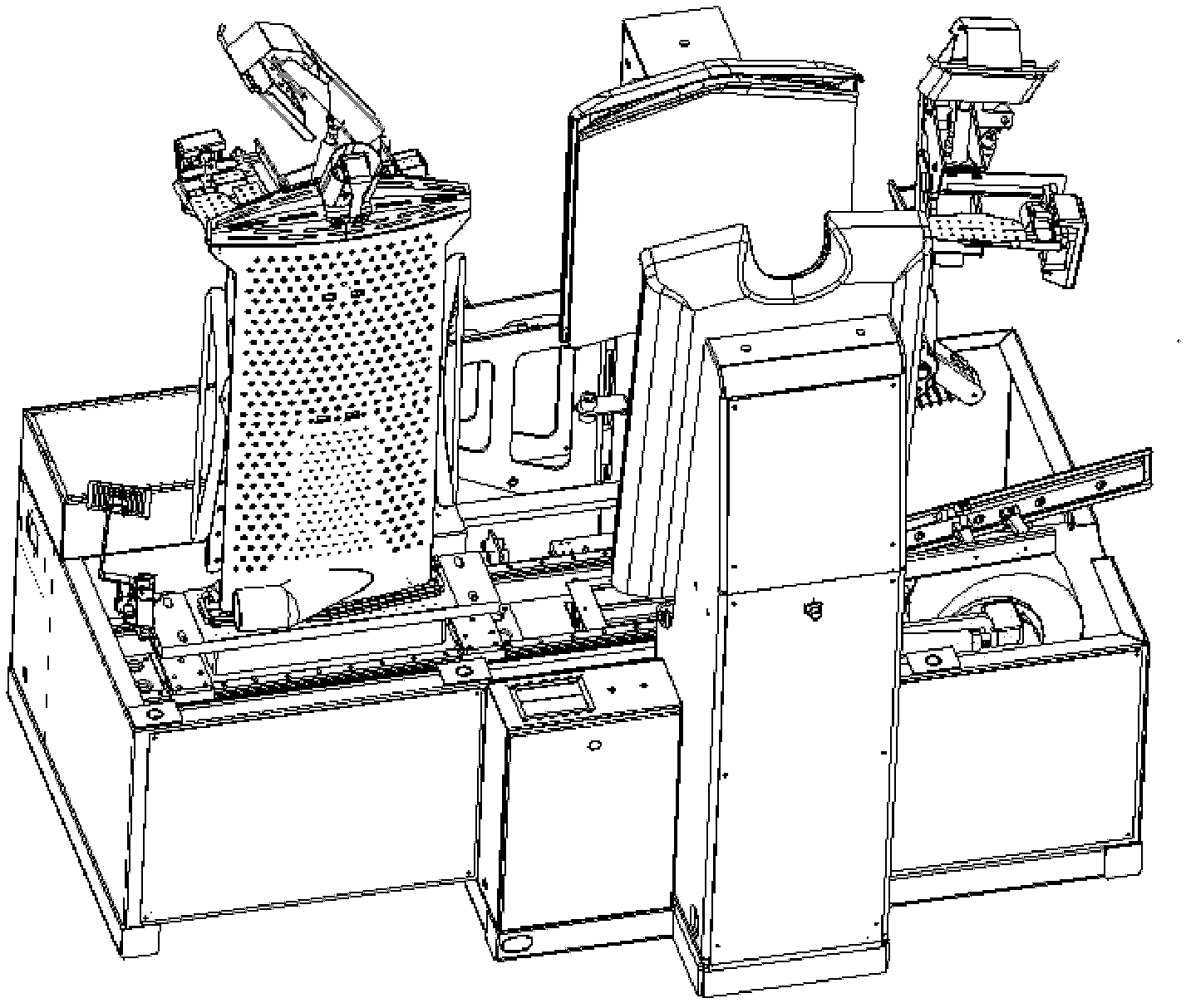

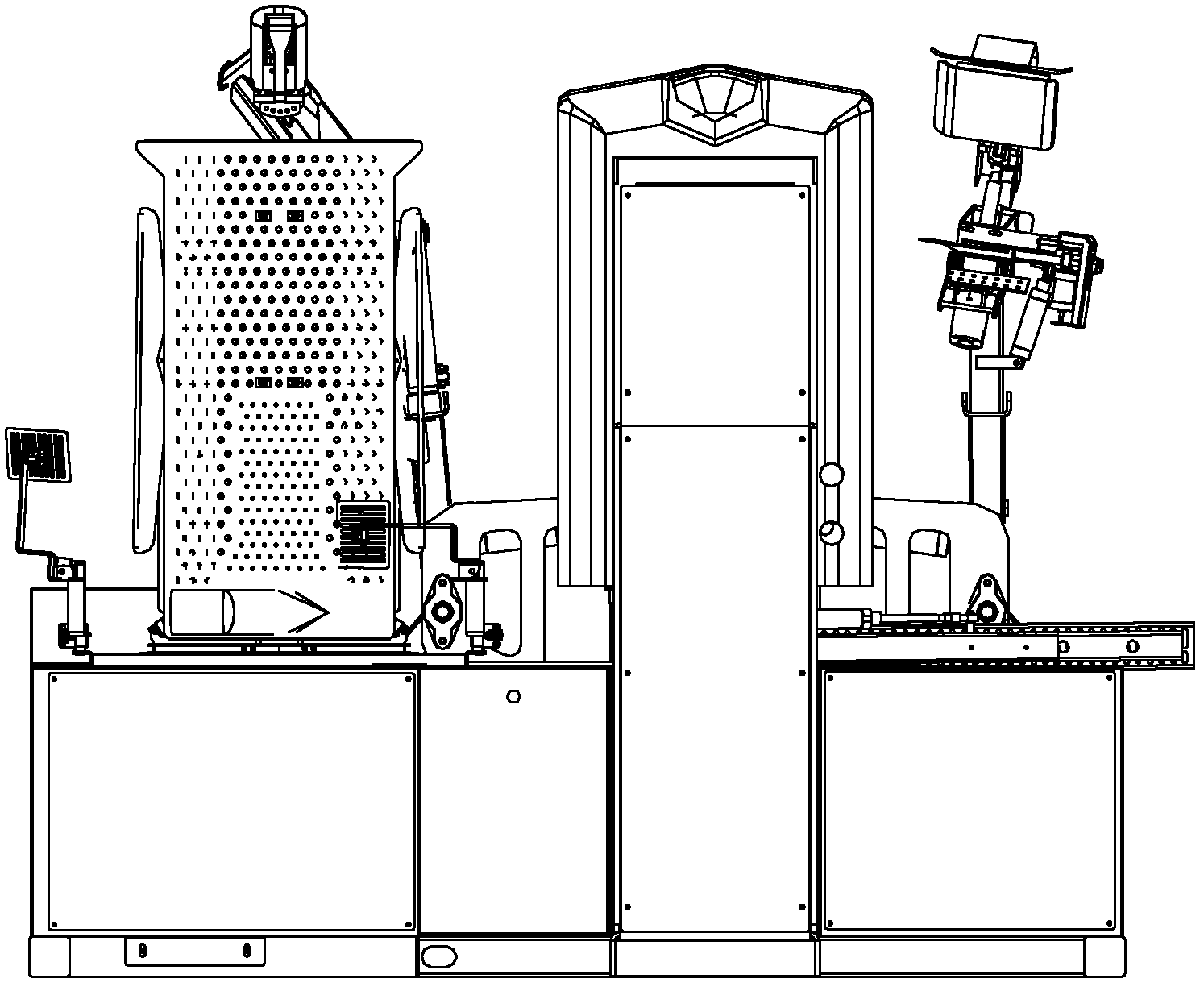

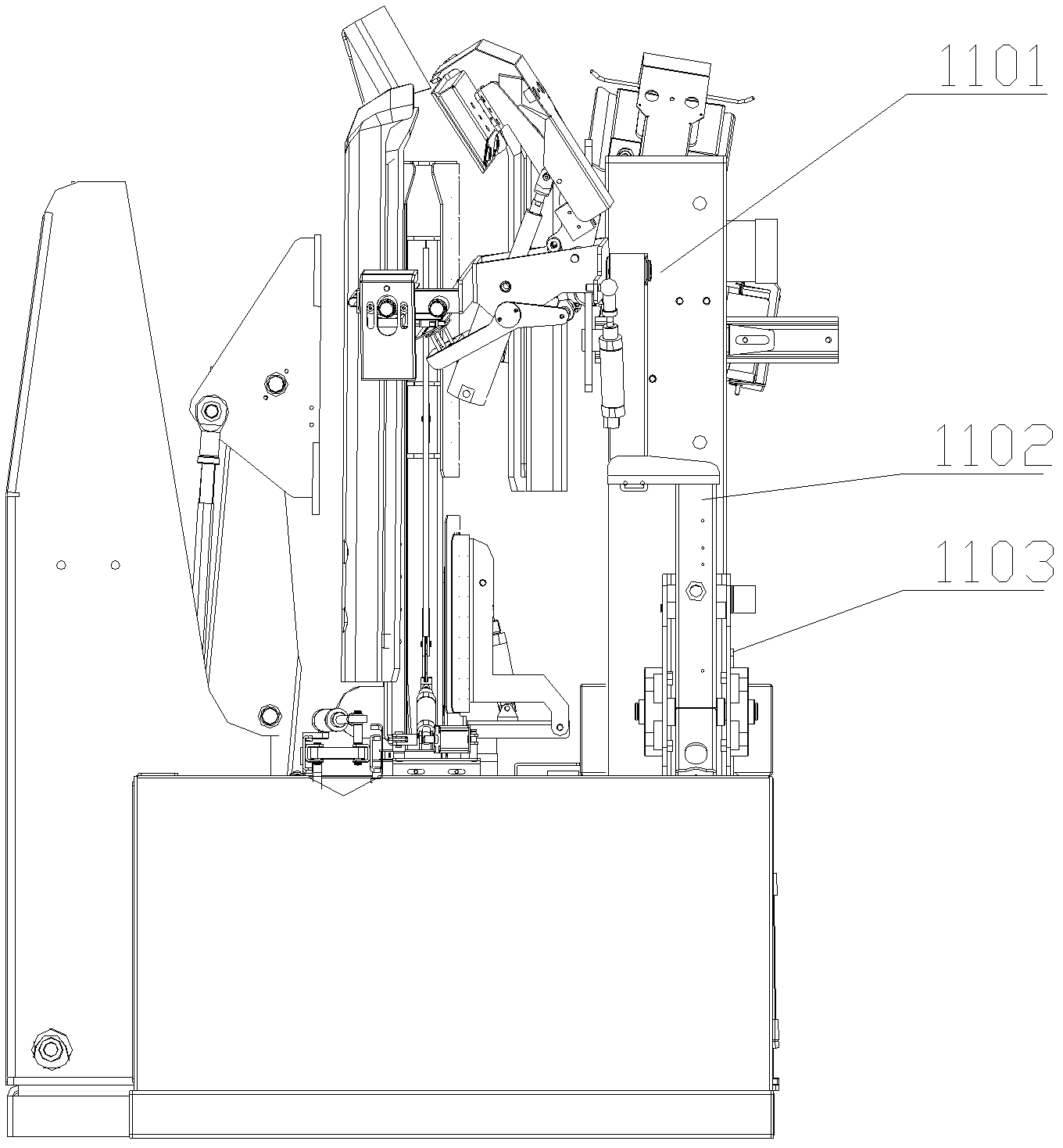

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] as attached figure 1 , 2 , 3, 4, 5 and 6, a multifunctional shirt ironing machine, which includes a base 1, a vacuum pump 2 is installed on the left side of the base 1, and a fan 3 is installed on the right side of the base 1, and the base 1. A heat exchanger 4 is installed on the workbench. The workbench of the heat exchanger 4 is equipped with a horizontal intermediate mold moving guide rail 5. The rectangular intermediate mold device 6 is installed on the intermediate mold moving guide rail 5. The rectangular intermediate mold device 6 is equipped with There is an air injection mechanism 601 for the middle mold, and the air injection mechanism 601 for the middle mold is connected with an external air source.

[0034] The left side platen mechanism 7 is fixedly installed on the left side of the rectangular middle mold device 6, and the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com