Method for manufacturing pneumatic tire

A manufacturing method and technology of pneumatic tires, applied to pneumatic tires, tire parts, tires, etc., can solve problems such as insufficient adhesion, durability problems, and deterioration of the fixed state of sound-absorbing parts, so as to achieve easy installation and improved durability Sex, good sound-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

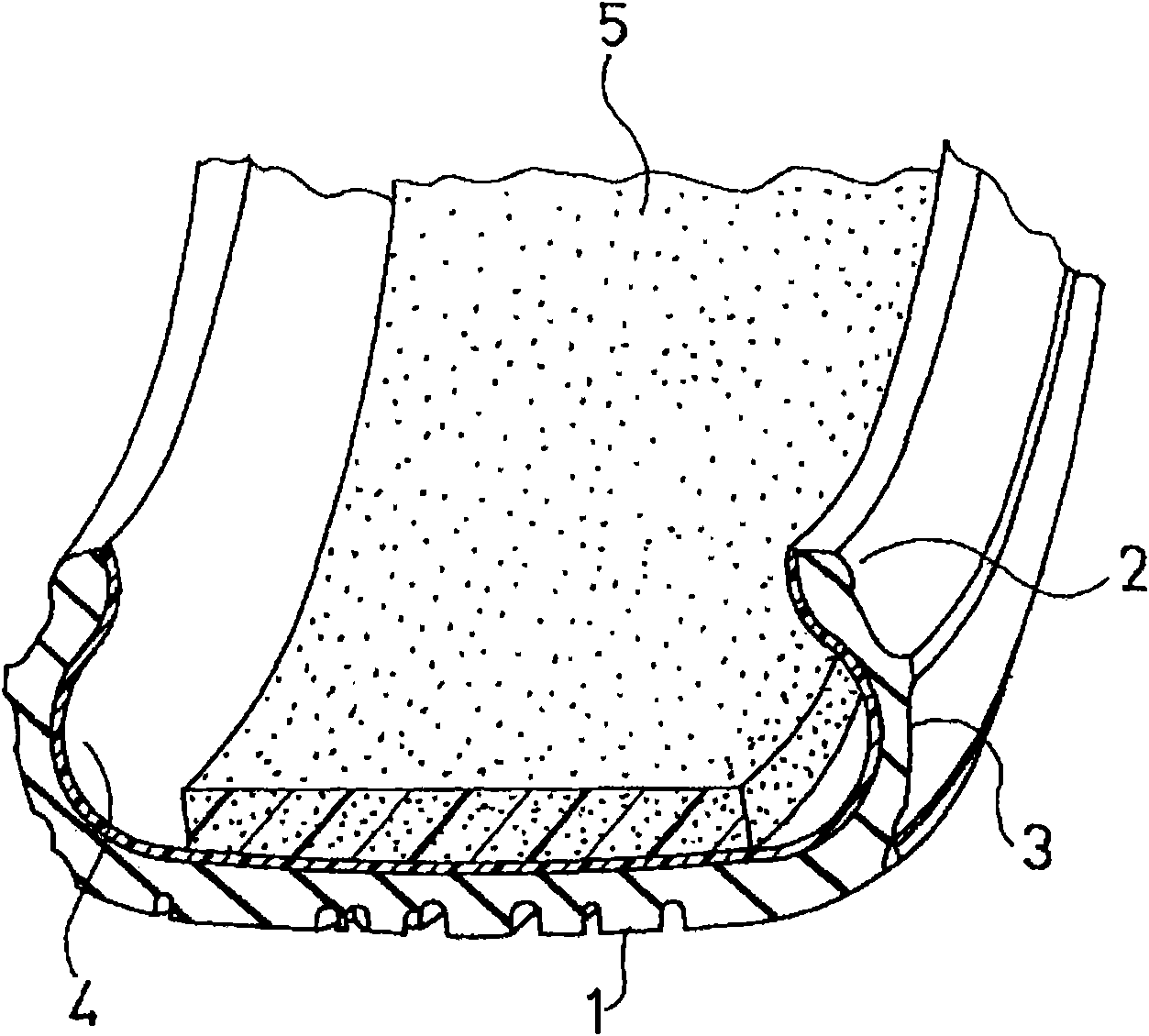

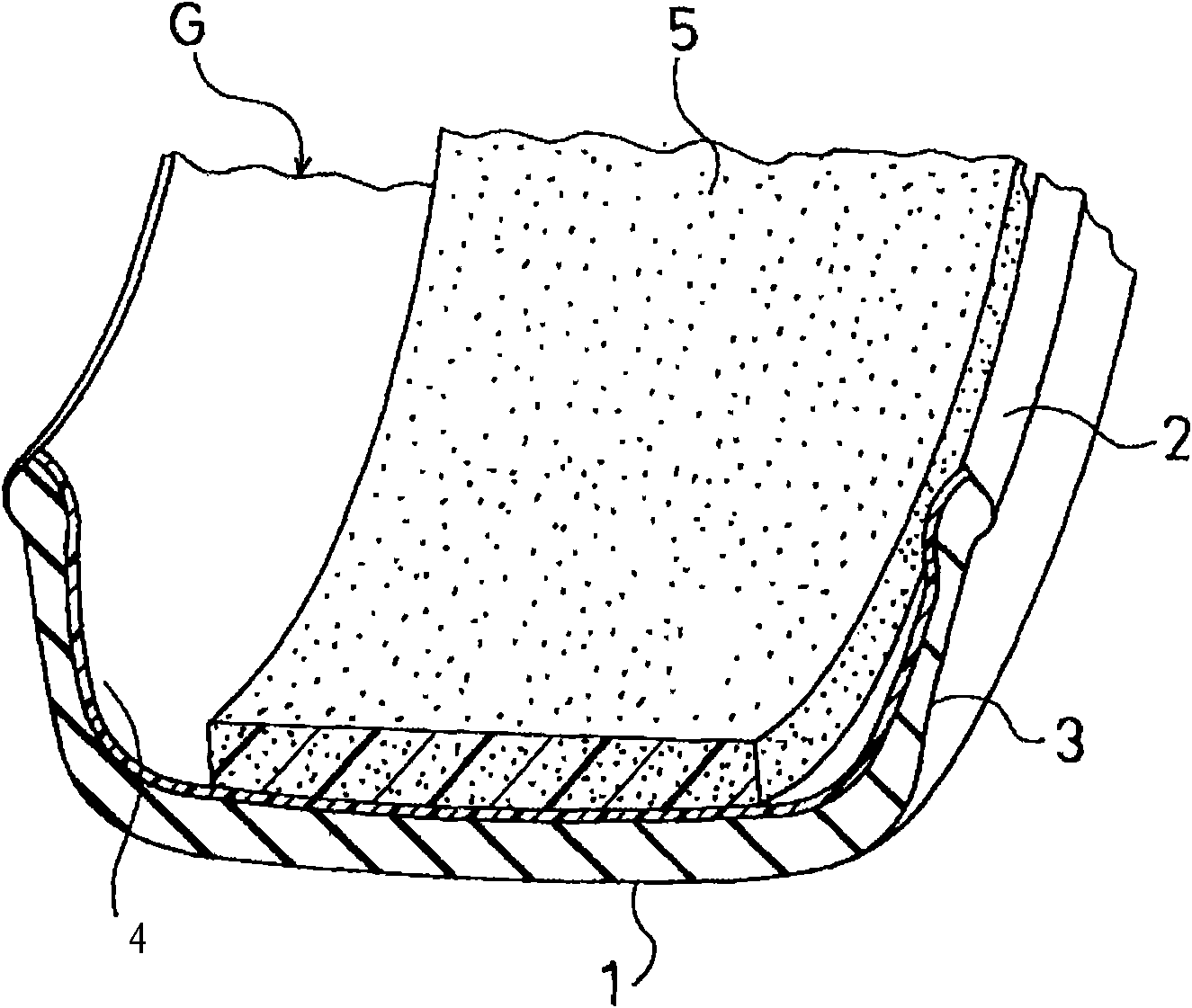

[0040] Pneumatic tires with a tire size of 215 / 60R16 95H and a sound-absorbing member made of polyurethane foam fixed to the inner liner on the inner surface of the tire were manufactured using different manufacturing methods (Examples 1 to 2 and Comparative Examples 1 to 3). In addition, in the manufacturing process of the above-mentioned pneumatic tire, the rise rate of the carcass layer was 140%, and a polyurethane foam with an elongation rate of 160% was used.

[0041] In Example 1, an inner liner composed of a thermoplastic elastomer composition in which an elastomer (bromobutyl rubber) is dispersed in a thermoplastic resin (nylon 6, 66) was used, and the soft material was molded by flame bonding. A sound-absorbing member made of polyurethane foam is fixed to a green tire on the inner liner, and the green tire is then vulcanized.

[0042] In Example 2, using an inner liner made of the same thermoplastic elastomer composition as in Example 1, a green tire was formed in whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com