Extrusion, cutting and insulation integrated machine

An all-in-one machine and heat preservation box technology, which is applied in dough forming and cutting equipment, dough forming machinery or equipment, horizontal installation tools for mixing/kneading, etc., can solve low work efficiency, high cost, and poor taste of knife-cut steamed buns and other issues, to achieve the effect of reasonable structural design, high work efficiency and rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

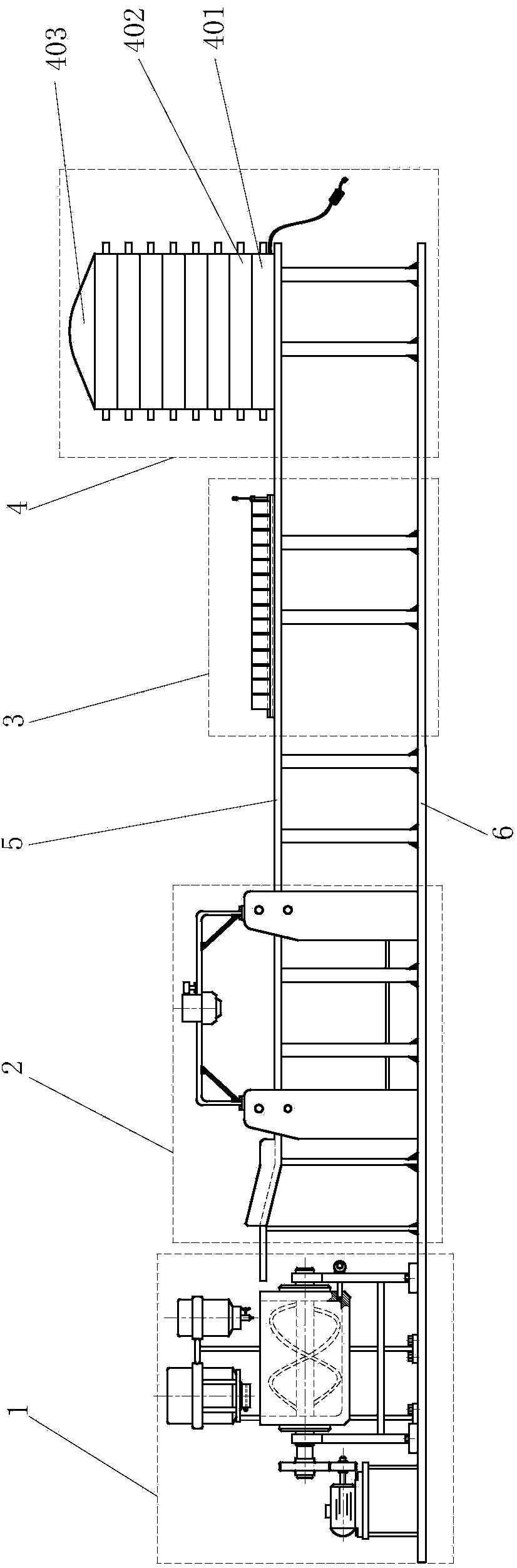

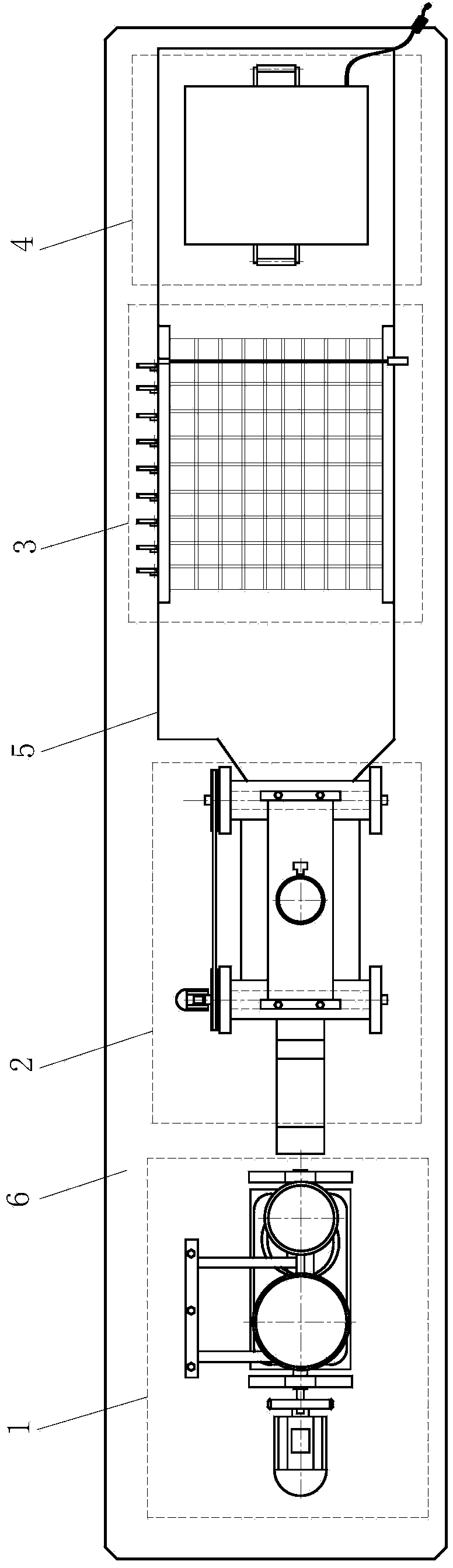

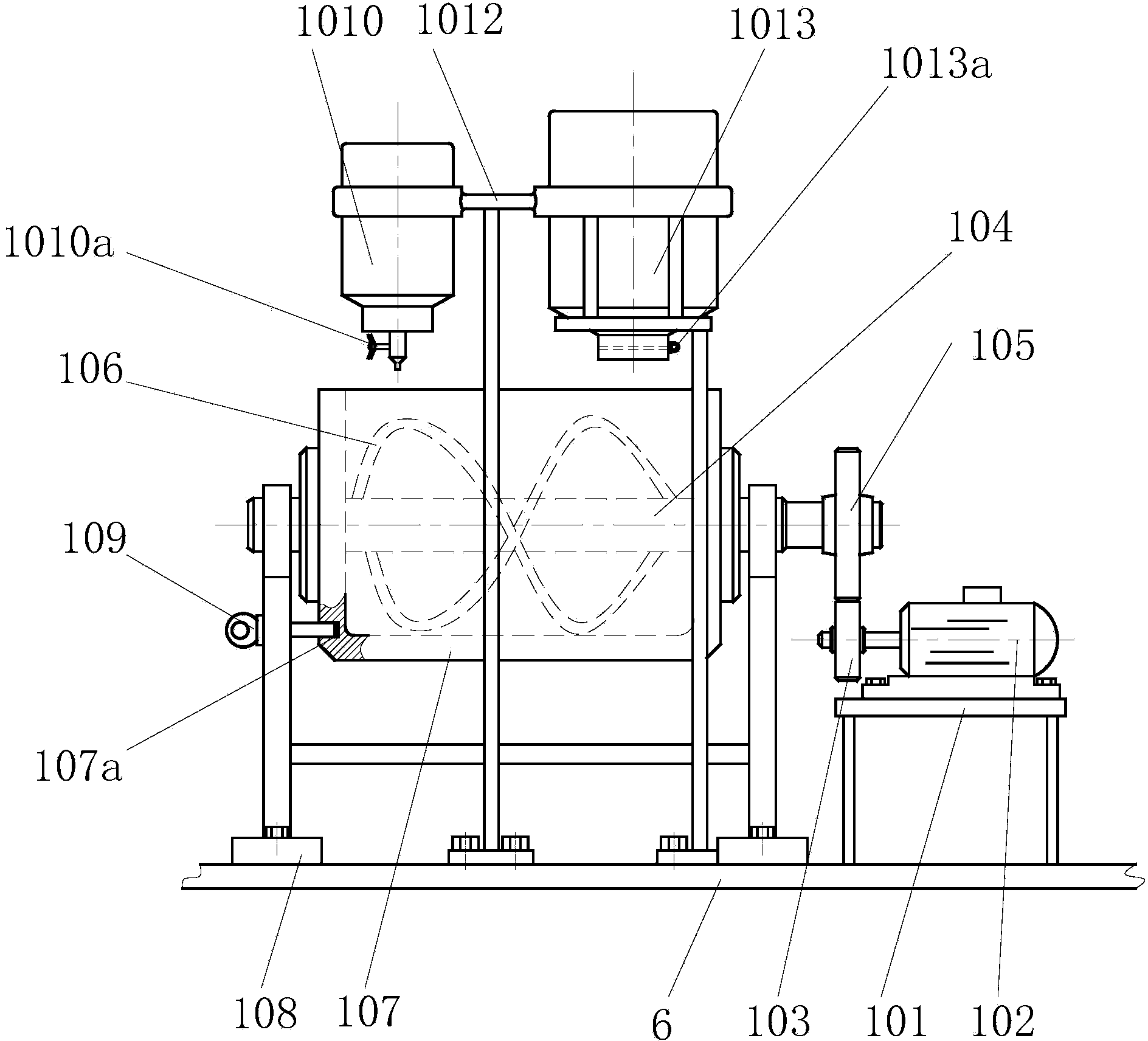

[0032] like Figure 1 to Figure 16 As shown, an extrusion, cutting, and heat preservation integrated machine includes a dough mixing device 1, a noodle pressing device 2, a cutting device 3, a proofing device 4, a chopping board 5 and a base 6, and the dough mixing device 1 is installed on the base 6 On the left side, the noodle pressing device 2 is located on the right side of the noodle making device 1, and the noodle pressing device 2 is installed on the base 6, and the chopping board 5 is positioned on the right side of the noodle pressing device 2, and the chopping board 5 is fixed on the top of the base 6, so The cutting device 3 is located on the right side of the noodle pressing device 2, and the cutting device 3 is fixedly connected to the chopping board 5, and the proofing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com