Sound suspending polishing device for nanometer mechanics characterization sample

A technology of acoustic suspension and mechanics, applied in the preparation of test samples, etc., can solve problems such as poor applicability and poor polishing effect, and achieve the effects of good applicability, improved dispersion, and uneven scratch size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

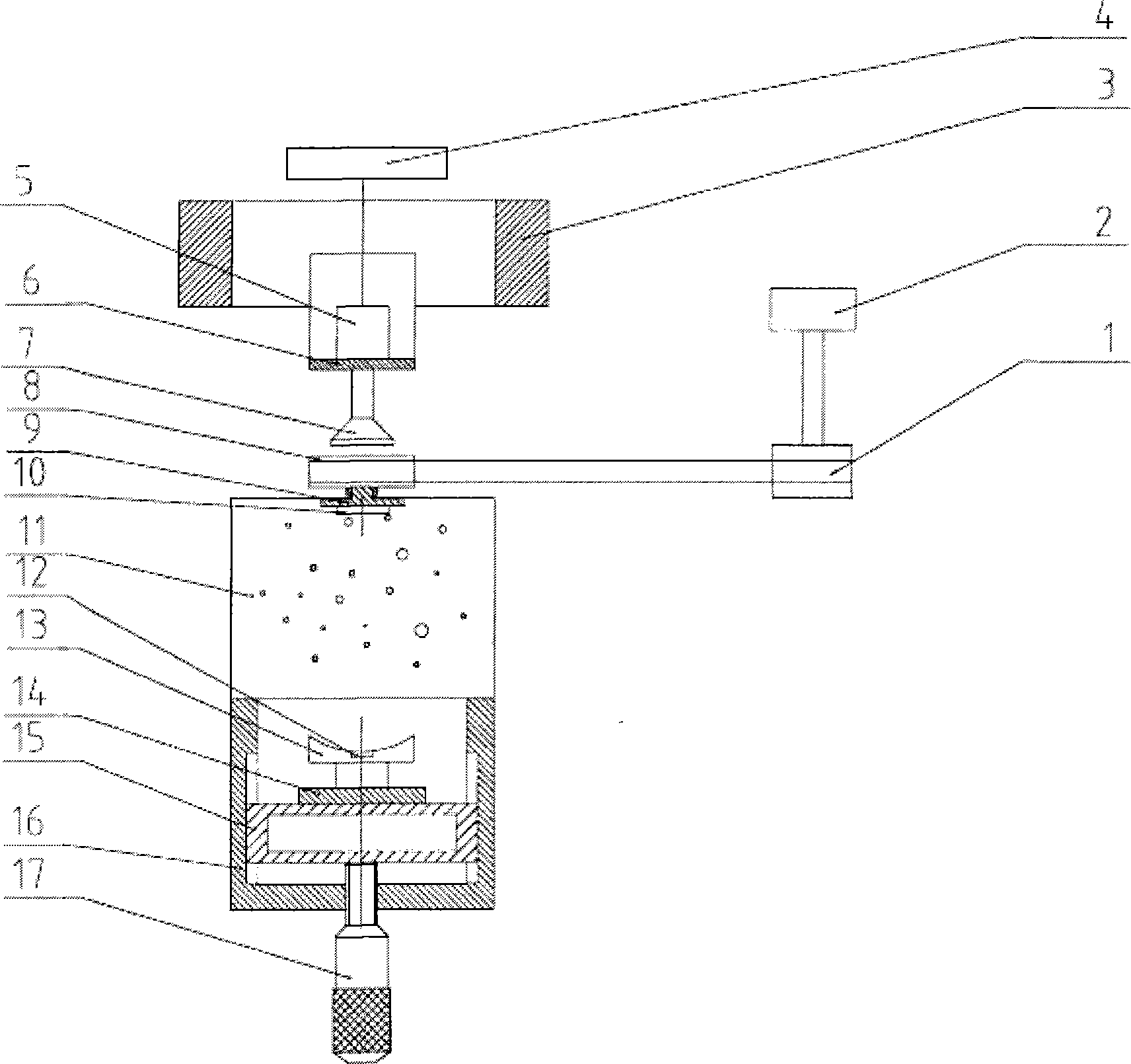

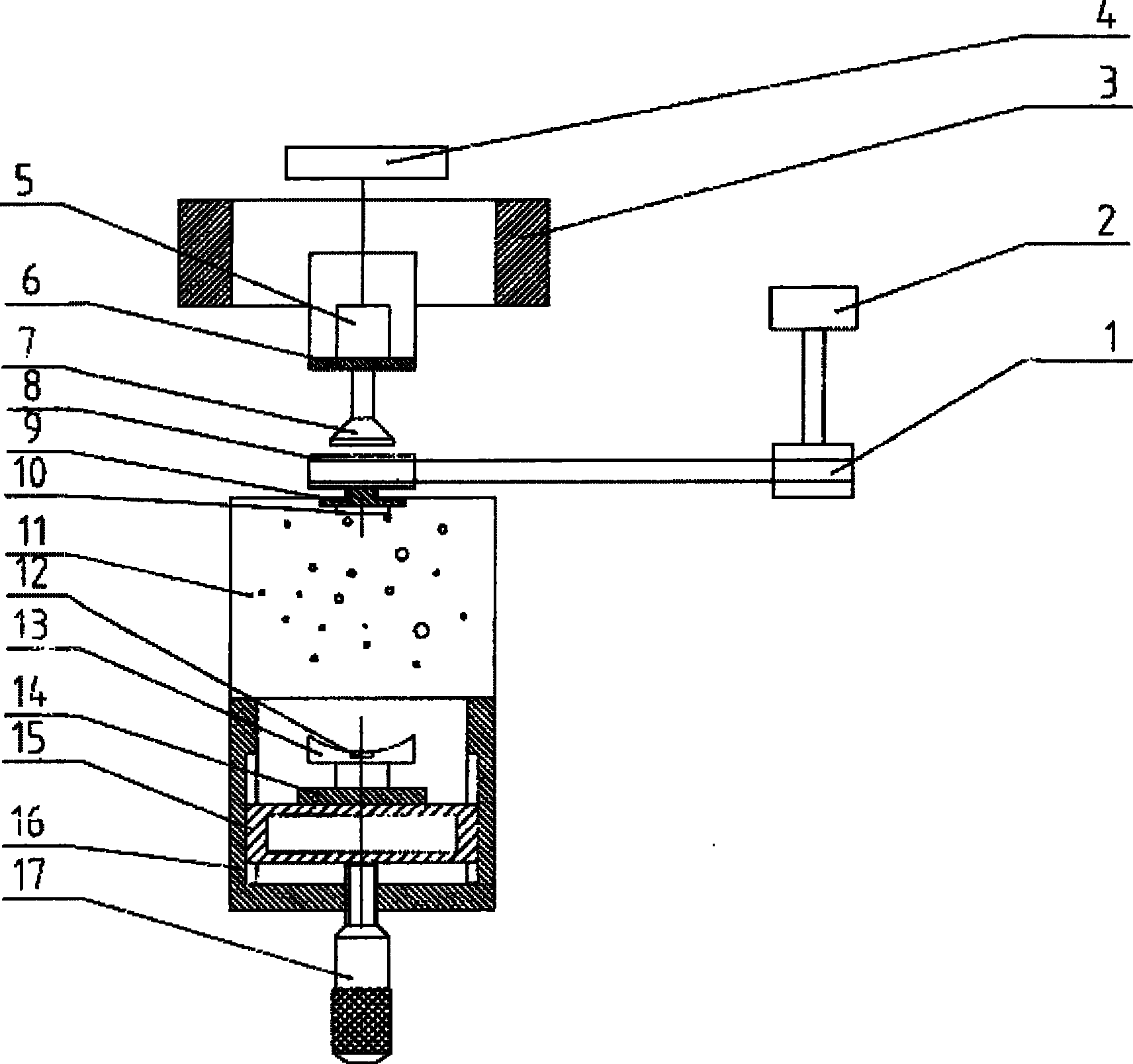

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] refer to figure 1 , a kind of acoustic levitation polishing equipment for nanomechanical characterization samples, including a frame, a pulse power supply 4, a fixture 9 for clamping a workpiece to be processed, an ultrasonic transducer 7, a container 11 for storing polishing liquid, an ultrasonic reflection end and a tuning mechanism for adjusting the distance between the ultrasonic reflection end 13 and the ultrasonic transducer 7, the ultrasonic transducer 7, the container 11 and the tuning mechanism are all installed on the frame, the pulse power supply 4 and the The ultrasonic transducer 7 is connected, the container 11 is located below the ultrasonic transducer 7, the clamp 9 is located above the container 11, the clamp 9 is connected to the pulley transmission mechanism, and the ultrasonic reflection end 13 is located below the container 11, the ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com