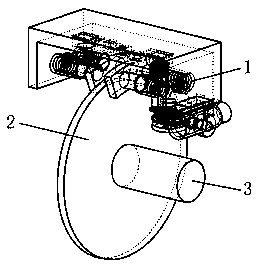

Automobile brake device

A technology of automobile brakes and automobiles, which is applied in the field of automobile brakes, and can solve problems such as shortening the service life of brake pads and brake discs, accelerating the wear speed of brake pads, and increasing the number of brake pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

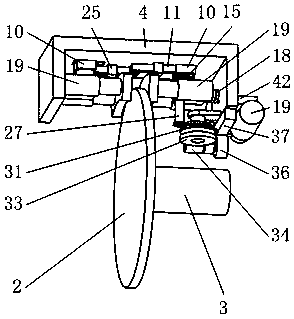

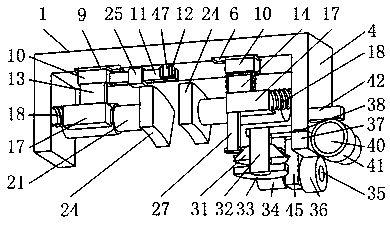

[0056] The specific embodiment: when the automobile does not need to brake, the driver does not step on the brake pedal, and the brake pad 24 is positioned at the initial position and does not move;

[0057] When the car in the driving state brakes normally, the driver slowly steps on the brake pedal; the brake pedal activates the vacuum booster; the vacuum booster controls the operation of the brake master cylinder, so that the hydraulic oil enters the hydraulic pressure instantaneously under the action of pressure. Cylinder 41; the hydraulic oil in the hydraulic cylinder 41 pushes the hydraulic column 40 to slide outside the hydraulic cylinder 41; the hydraulic column 40 drives the worm 34 to rotate through the third connecting block 39, the rack, the gear and the second shaft 35; the worm 34 drives the worm gear 33 rotation; the worm wheel 33 drives the tapered thread drive wheel 31 to rotate through the first shaft 32; the star wheel 28 moves relative to the tapered thread ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com