Urban railway transport vibration attenuation turnout structure

A technology for urban rail transit and turnouts, which is applied in the direction of tracks, roads, buildings, etc., and can solve the problem of fastener system stability, pull-out resistance, vibration reduction effect reduction, and vulcanized vibration-damping fasteners that have not been popularized and applied in a large area. Affect the service life of the turnout and the surrounding environment, etc., to achieve the effect of gauge maintenance ability and high safety, reliable fastener connection, and enhanced pull-out resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

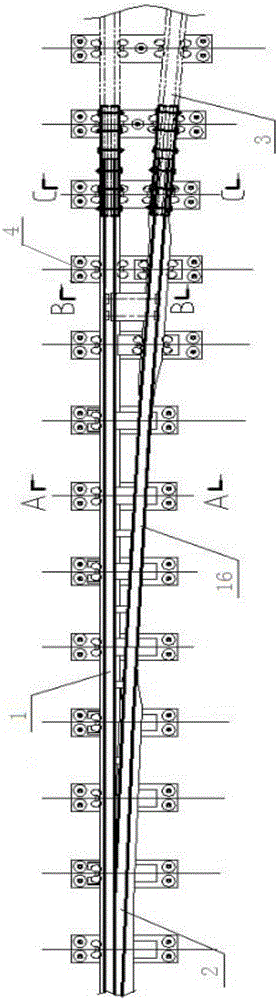

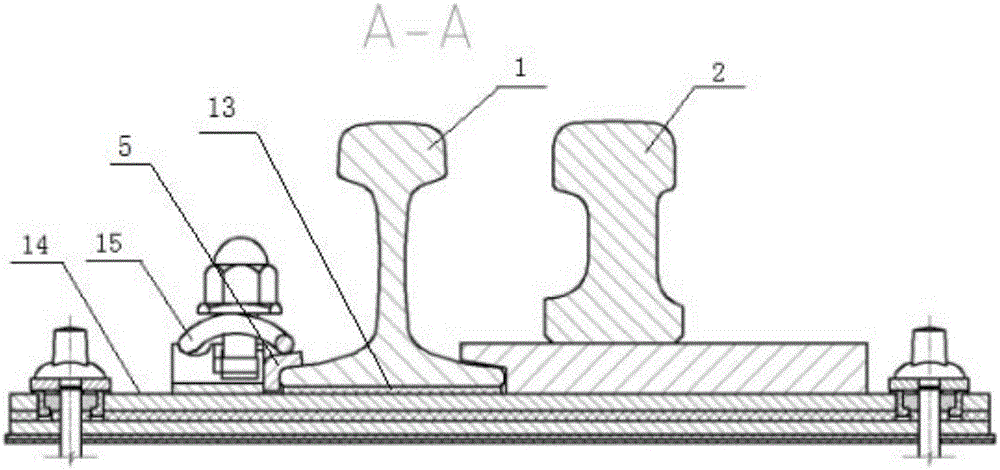

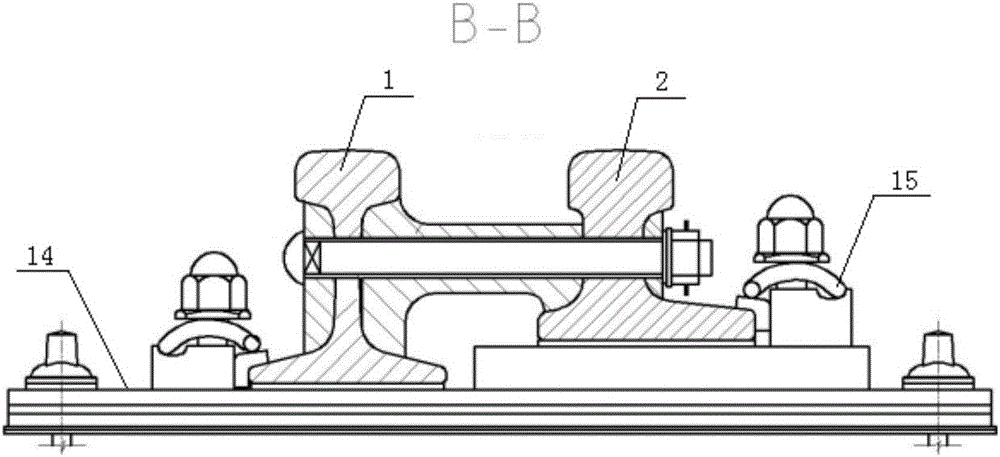

[0017] combined with figure 1 , 2 , 3, 4, 5 describe an embodiment of the present invention.

[0018] An urban rail transit vibration-damping turnout structure, comprising a basic rail 1, a point rail 2 and a guide rail 3, the basic rail 1, the point rail 2 and the guide rail 3 are all installed on the track bed through a vibration-damping fastener system 4; The heel end of the rail 2 has an elastic bendable section 16, and the width of the rail limb on the working side side of the elastic bendable section 16 is smaller than the width of the rail limb on the working side side of the other sections of the tip rail 2, that is, the working side of the elastic bendable section 16. 15-50mm is cut off on one side of the rail limb; the joints of the basic rail 1, the tip rail 2 and the guide rail 3 are connected by the vibration-damping joint splint 17 and the common joint splint 18, and the vibration-damping joint splint 17 is installed on the non-working side On one side, the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com