Sanding pressure control regulator

A pressure regulator and pressure control technology, which is applied in the direction of wheel adhesion, wheel, transportation and packaging, etc., can solve the problems of increasing pressure regulating equipment, increasing manpower and material cost, and large sanding wind pressure, so as to achieve the goal of reducing space Requirements, strong versatility, and exquisitely designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

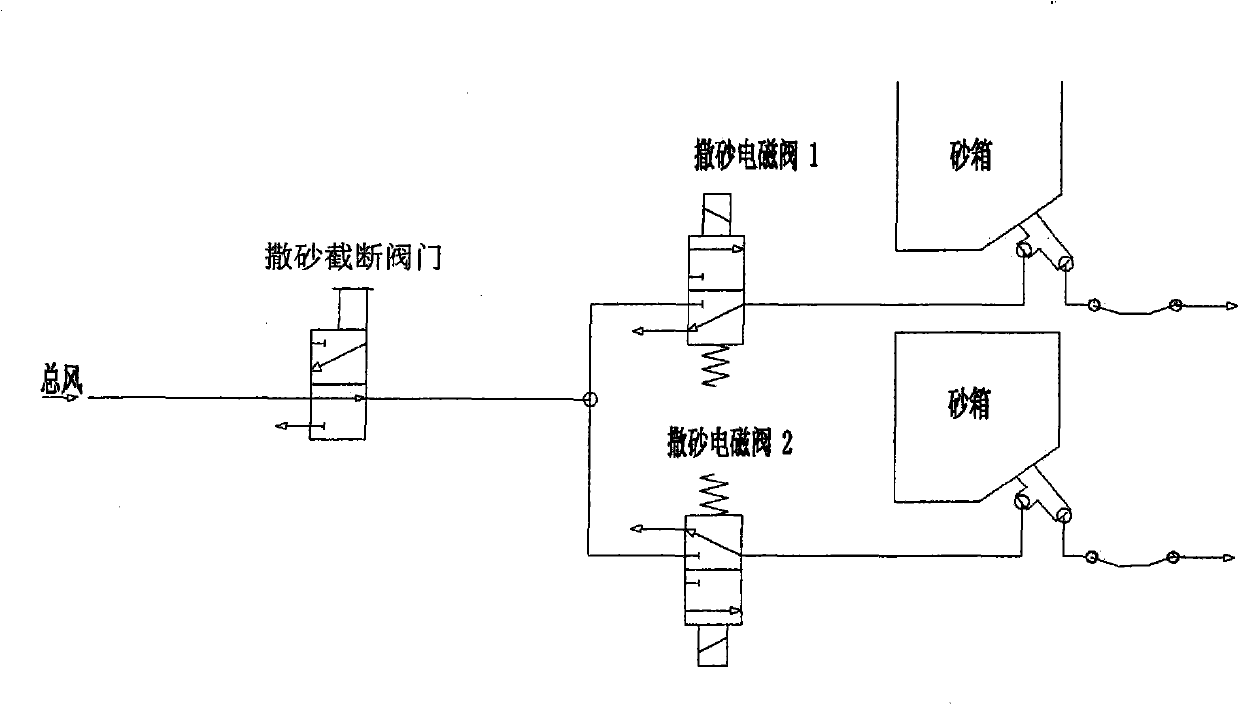

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Although the technical solution of the present invention is described with the following preferred embodiments, it does not constitute any limitation to the substantive technical solution of the present invention.

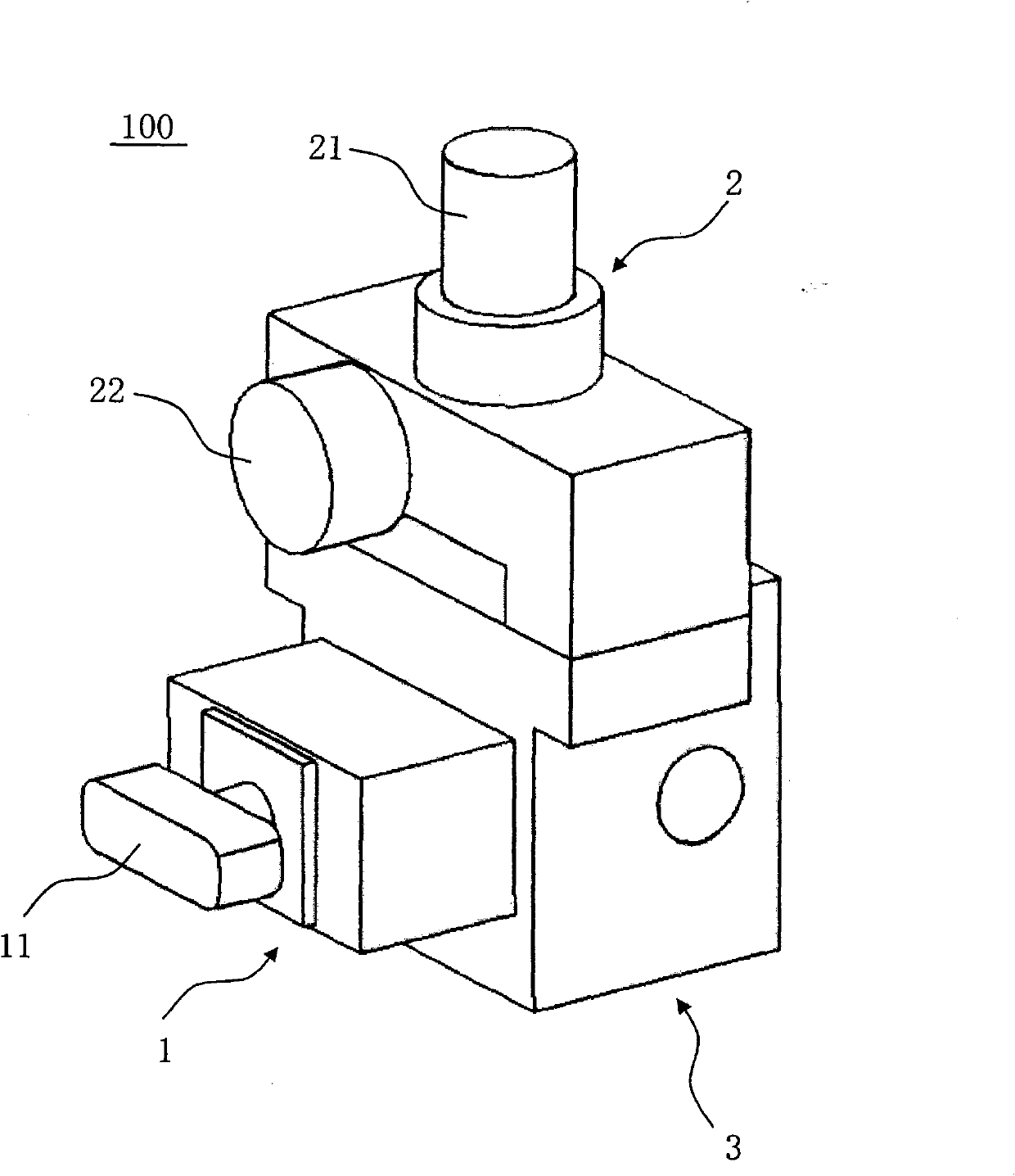

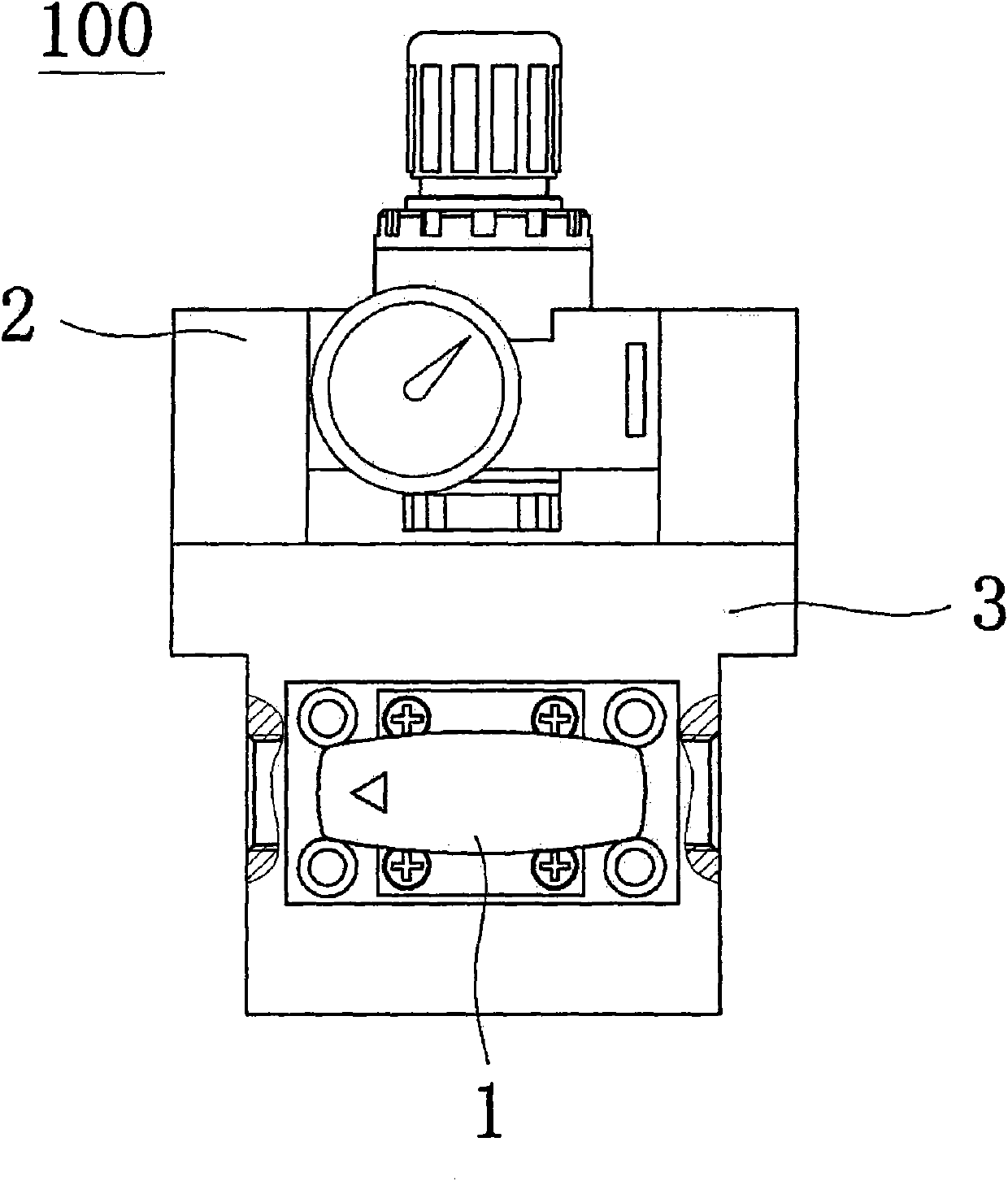

[0057] Please refer to figure 2 , is the overall schematic diagram of the sanding pressure control regulator of the present invention, as shown in the figure, the sanding pressure control regulator 100 mainly includes a cut-off plug 1, a pressure regulator 2 and an air circuit board 3, and the air circuit board 3 is equipped with a special A plurality of designed air passages, cut-off plugs 1 and pressure regulators 2 are integrated and fixed on the air circuit board 3, for example, more common hexagonal bolts can be s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com