Three-dimensional printing equipment and method

A technology of three-dimensional printing and equipment, applied in the field of three-dimensional printing, can solve the problems of low forming accuracy, high manufacturing cost, low material density of metal parts, etc., and achieve the effect of printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The object of the present invention is to provide a three-dimensional printing device and method.

[0049] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

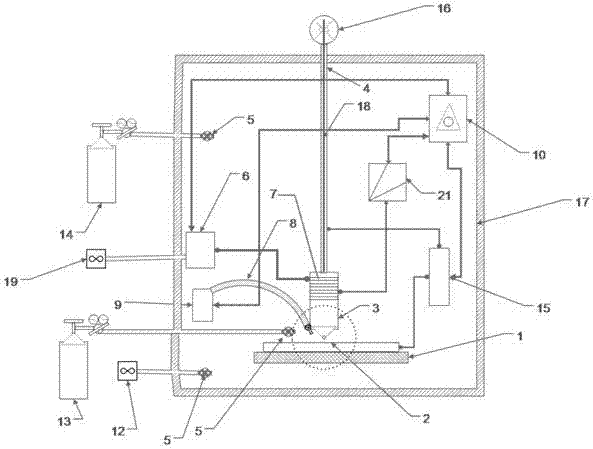

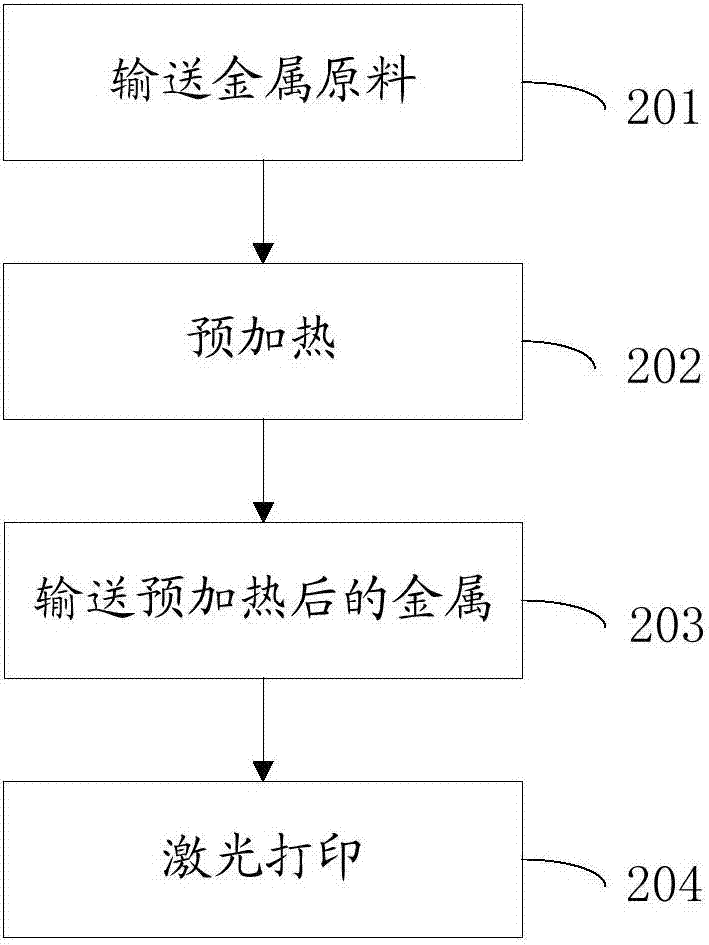

[0050] like figure 1 As shown, a three-dimensional printing equipment includes a metal raw material conveying device 16, a high-frequency magnetic field preheating device, a position driving device, a laser control device, a print head 3, a sensor group 5 and a controller 10;

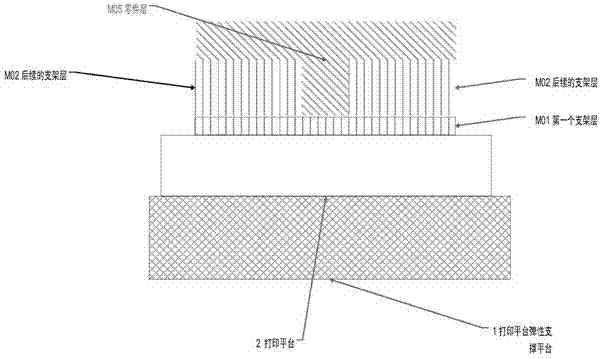

[0051] The print head 3 includes a material input port and a material output port, and the material input port and the material output port are respectively arranged at two ends of the print head;

[0052] The metal raw material conveying device communicates with the raw material input port of the print head 3 through the pipeline 4, and is used to tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com