3D printer head with replaceable nozzle for rapidly forming large products

A technology for 3D printers and large-scale products, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve problems such as time-consuming, difficult to form, and difficult to balance printing efficiency and printing accuracy at the same time, so as to improve printing efficiency, The effect of simplifying the printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

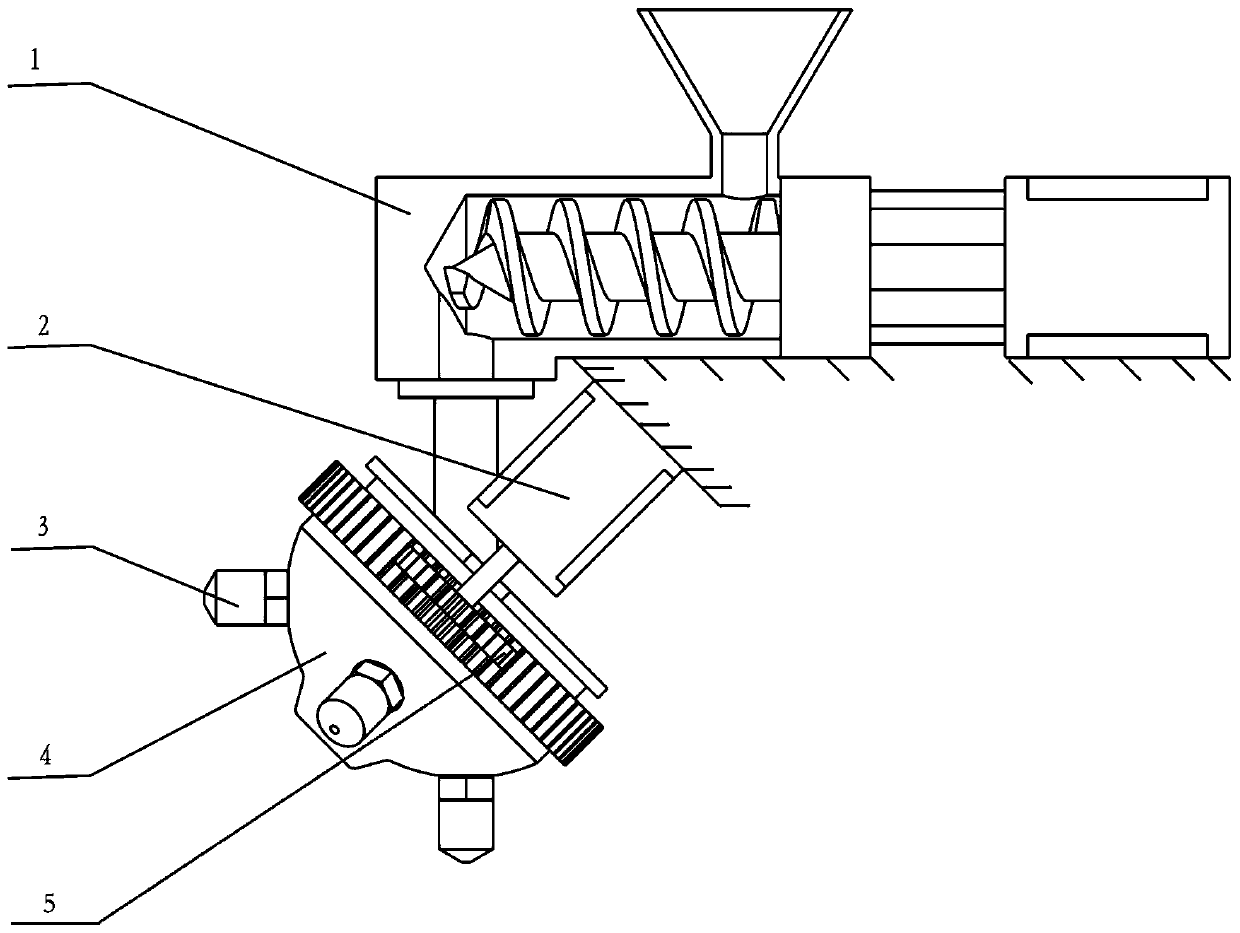

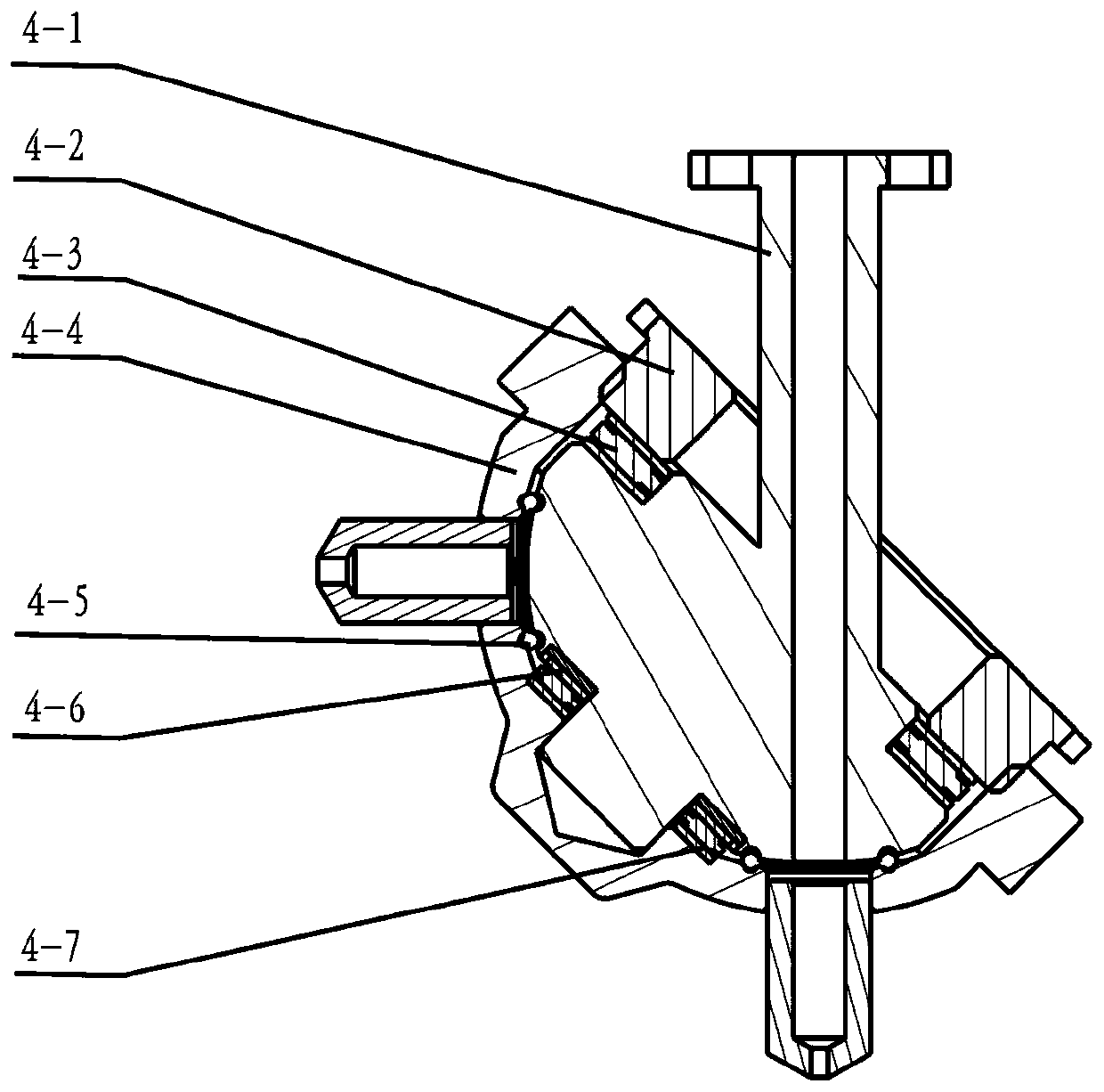

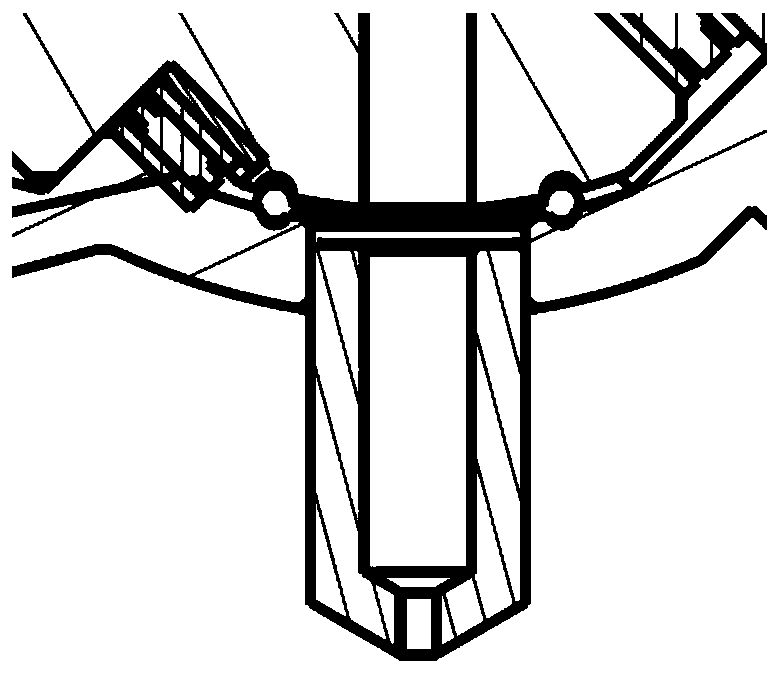

[0018] The present invention proposes a replaceable nozzle 3D printer head for rapid prototyping of large-scale products, which is mainly composed of a melt extrusion unit, a nozzle group unit and a nozzle conversion drive unit. The melt extrusion unit is a single-screw extruder 1, composed of figure 1 shown. The nozzle group unit consists of inner core valve 4-1, compression cover 4-2, thrust needle roller bearings 4-3 and 4-7, nozzle fixing cover 4-4, nozzle 3, sealing ring 4-5, rubber ring 4- 6 composition. The nozzle conversion driving unit is composed of a motor 2 and a gear 5 . There are pipelines and flanges on the inner core valve 4-1 so that it can be connected with the screw extruder 1, and the inner core valve 4-1 is also provided with a hemispherical structure, which is used to cooperate with the nozzle fixing cover 4-4. There are 4 threaded holes under the nozzle fixing cover 4-4 for the nozzles 3 of different apertures to be screwed together. The nozzle fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com