Capsule extrusion type functional food 3D printing material as well as preparation method and application thereof

A functional food and 3D printing technology, which is applied in the direction of oil-containing food ingredients, food freezing, food ingredients, etc., can solve the problems of low stability of nano-emulsions, public nuisance, human irritation, and unsuitability for direct consumption, etc., to achieve good results. Application prospects and market value, easy cleaning and maintenance, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

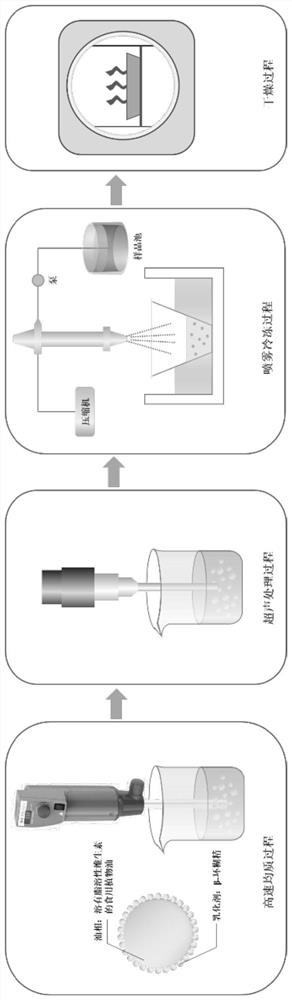

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Preparation of capsule extrusion food 3D printing material rich in vitamin A1

[0023] 1.1 Preparation materials:

[0024] Vitamin A1: Sinopharm Chemical Reagent Co., Ltd.

[0025] β-cyclodextrin: Sinopharm Chemical Reagent Co., Ltd.

[0026] Corn oil: Yihai Kerry Arowana Grain, Oil and Foodstuffs Co., Ltd.

[0027] Magnesium stearate (food grade): Zhejiang Yinuo Biotechnology Co., Ltd.

[0028] 1.2 Preparation steps:

[0029] ①Water phase preparation: Accurately weigh 2.4g of β-cyclodextrin and place in 80mL of distilled water, fully stir at 60°C for 30min, and prepare a β-cyclodextrin solution with a concentration of 30mg / mL.

[0030] ②Oil phase preparation: Accurately weigh 240mg vitamin A1 and dissolve in 120mL corn oil, stir magnetically at room temperature for 30min to form an oil phase.

[0031] ③High-speed homogenization: Add the oil phase to the water phase solution drop by drop at a rate of 1 drop / s, and stir and homogenize at a speed of 10,000r...

Embodiment 2

[0035] Example 2 Preparation of capsule extrusion food 3D printing material rich in vitamin D2

[0036] 2.1 Preparation materials:

[0037] Vitamin D2: Sinopharm Chemical Reagent Co., Ltd.

[0038] β-cyclodextrin: Sinopharm Chemical Reagent Co., Ltd.

[0039] Corn oil: Yihai Kerry Arowana Grain, Oil and Foodstuffs Co., Ltd.

[0040] Magnesium stearate (food grade): Zhejiang Yinuo Biotechnology Co., Ltd.

[0041] 2.2 Preparation steps:

[0042]①Water phase preparation: Accurately weigh 2.4g of β-cyclodextrin and place in 80mL of distilled water, fully stir at 60°C for 30min, and prepare a β-cyclodextrin solution with a concentration of 30mg / mL.

[0043] ②Oil phase preparation: Accurately weigh 240 mg of vitamin D2 and dissolve in 120 mL of corn oil, and magnetically stir for 30 min at room temperature to form an oil phase.

[0044] ③High-speed homogenization: Add the oil phase to the water phase solution drop by drop at a rate of 1 drop / s, and stir and homogenize at a spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com