Efficient flat pressing type cold transfer printing machine and process

A flat-press, cold-transfer technology, applied in transfer printing, flat-bed flat printing machines, printing processes, etc., can solve the problems of low production efficiency, high energy consumption, poor printing effect, etc., to improve efficiency and reduce labor , The effect of simplifying the printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

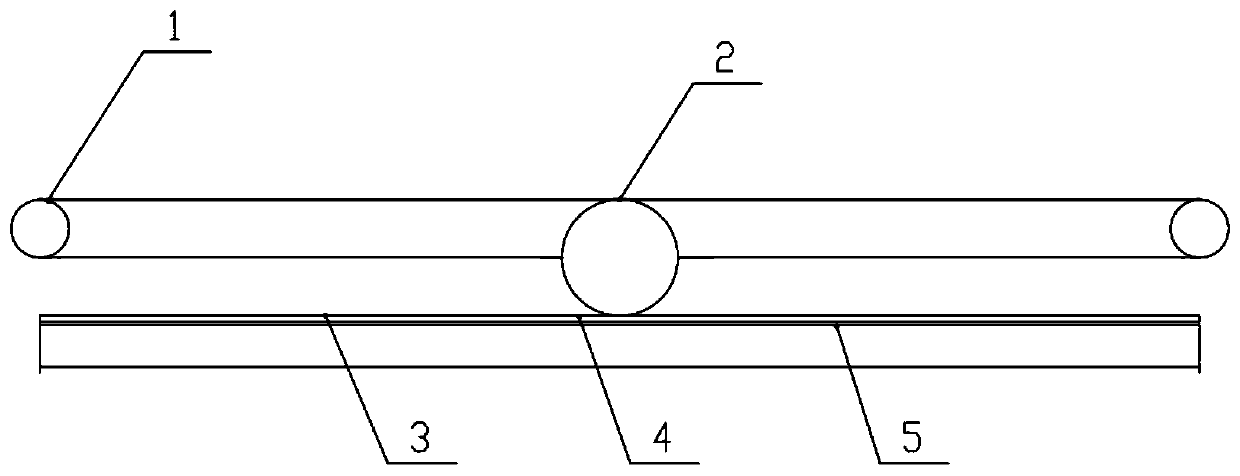

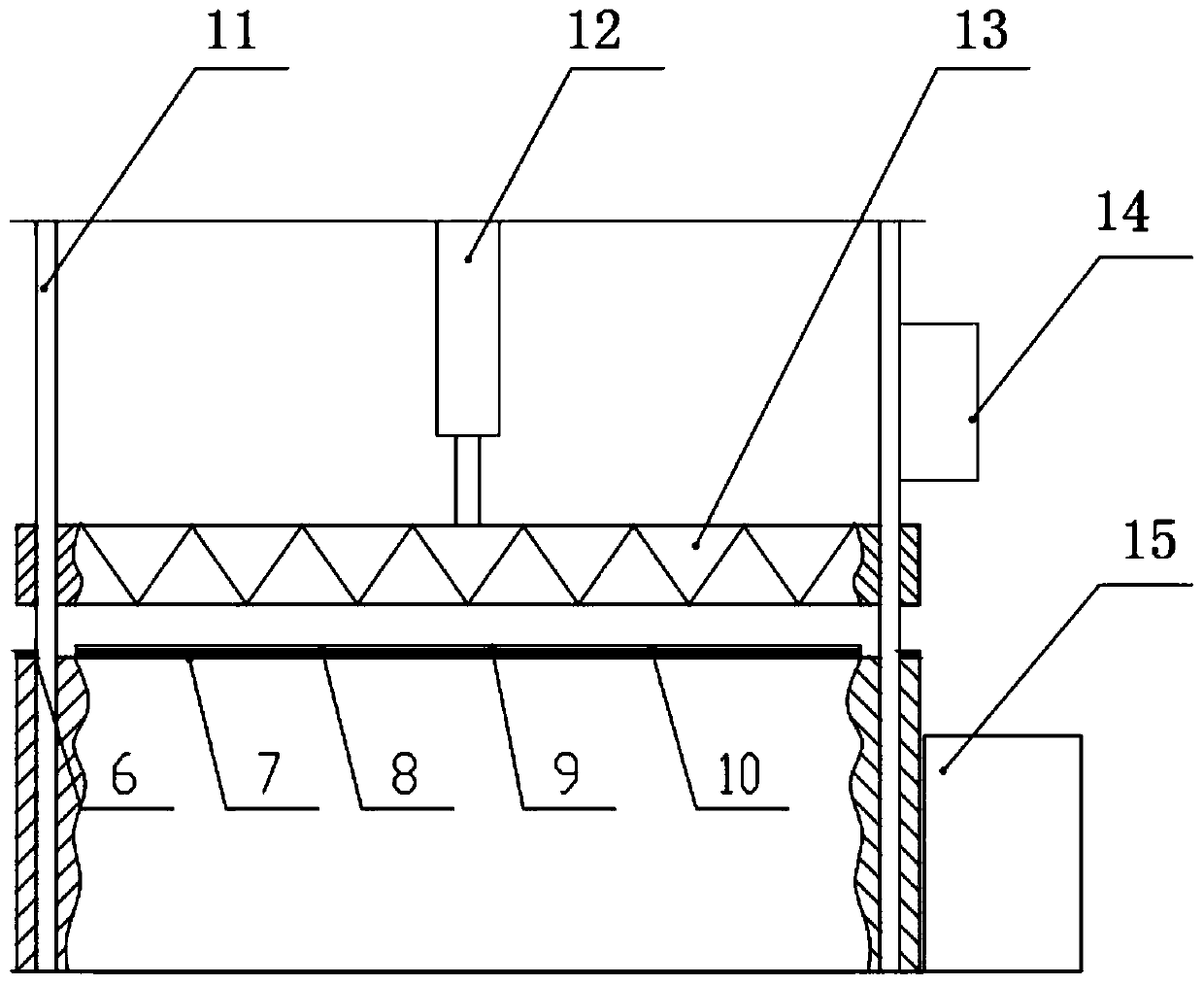

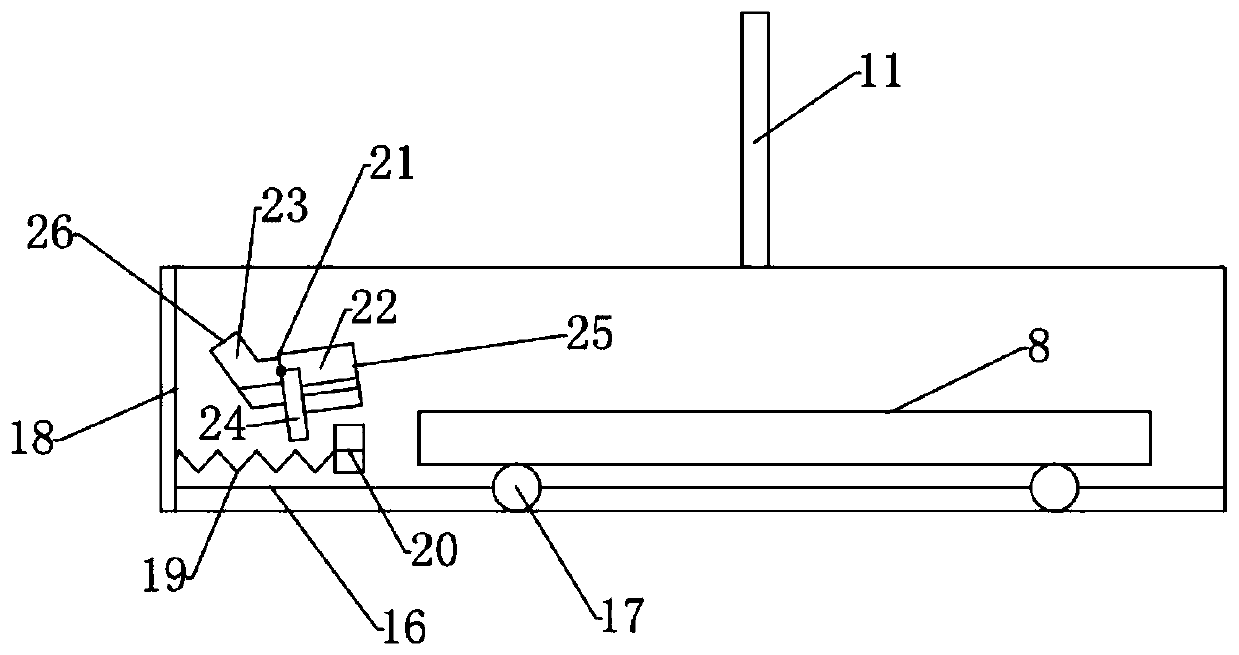

[0056] Such as figure 1 , figure 2 As shown, a flat-pressure cold transfer printing machine includes an electric control box 14, a hydraulic station 15, an upper platen 13, a support table 7, a fabric pallet 8 for accommodating the fabric to be printed, and limit blocks arranged at both ends of the support table 6. The upper platen 13 is arranged horizontally and horizontally. The top of the upper platen 13 is provided with a pressurized oil cylinder 12 electrically connected to the electric control box 14. A pair of guide posts 11 are provided at both ends of the support table 7, and the top of the guide post 11 is provided with There is a beam (not shown in the figure) connecting two guide columns 11, the top of the pressurized cylinder 12 is fixed in the middle of the beam, and the two ends of the upper pressure plate 13 are respectively sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com