Device for preparing continuous fiber reinforced resin-based composite component

A composite component and reinforced resin-based technology, which is applied in manufacturing auxiliary devices, additive processing, liquid material additive processing, etc., can solve problems such as high technical barriers, restrictions on rapid manufacturing and rapid repair of composite components for aerospace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

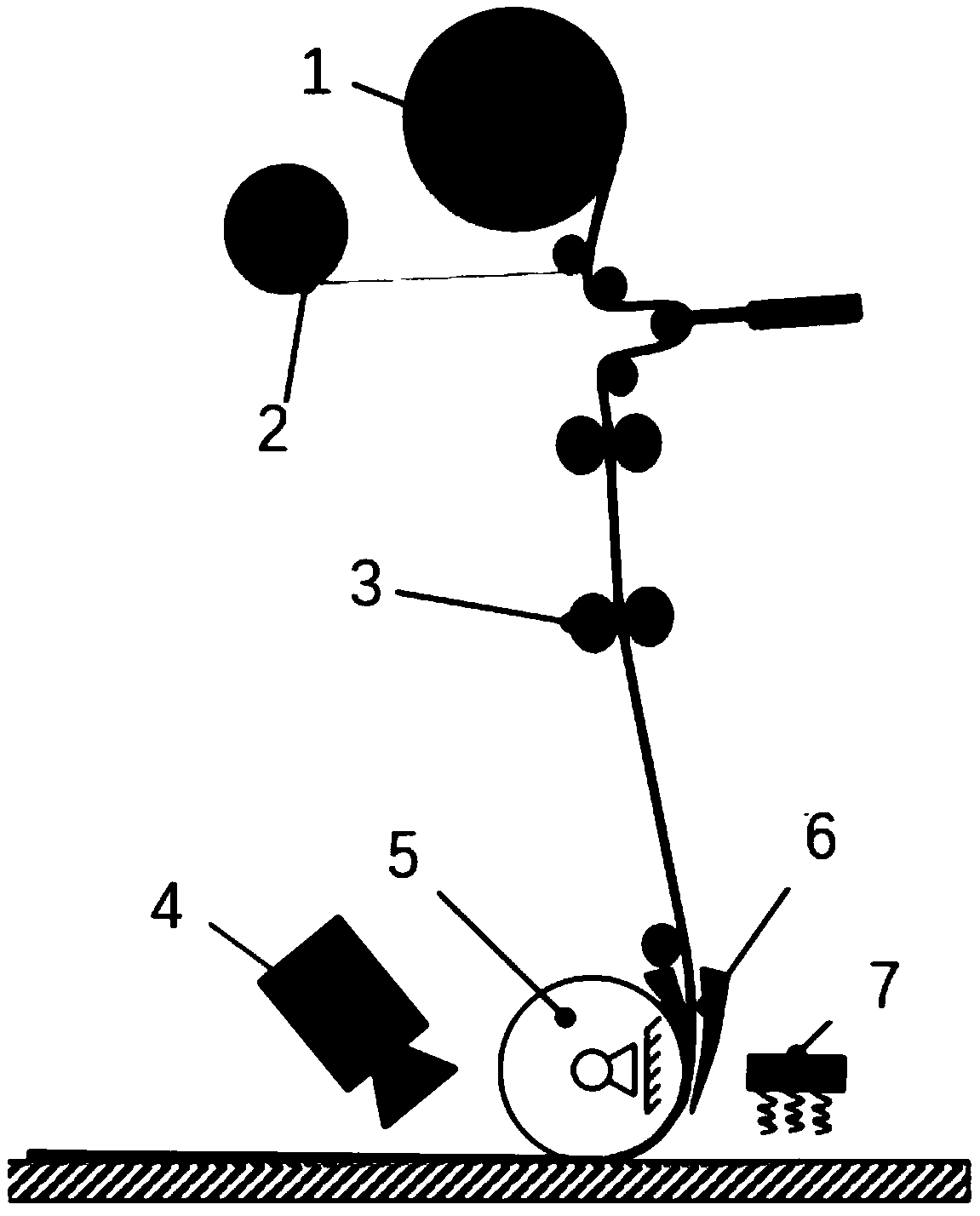

[0012] In order to make the technical means and creative features of the present invention more obvious and comprehensible, the present invention will be further described below in conjunction with the accompanying drawings.

[0013] Refer to attached figure 1 , a continuous fiber-reinforced resin-based composite member preparation device, the components used include a raw material storage tray, a tension stabilizing device, a feeding unit, a real-time monitor, a compacting roller, a material cutting unit and an infrared heater. The raw material storage disk is hollow and circular, and can rotate around the center of the fixed shaft. The raw material is narrow-band thermoplastic resin fiber prepreg. The thermoplastic resin can be engineering plastics such as nylon 6, nylon 66, polyphenylene sulfide or polyetheretherketone. The fiber can be carbon fiber, glass fiber or aramid fiber, and the fiber content is 30- 50wt%. The width of the narrow-band thermoplastic resin fiber pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com