High-speed 3D micro-nanometer printing control method, model slicing method and model slicing device based on femtosecond laser

A femtosecond laser and printing model technology, applied in the field of 3D micro-nano printing, can solve the problems of low printing accuracy, low printing efficiency, incomplete application of microstructure, etc., to reduce the amount of data, improve the speed, and improve the efficiency of program execution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

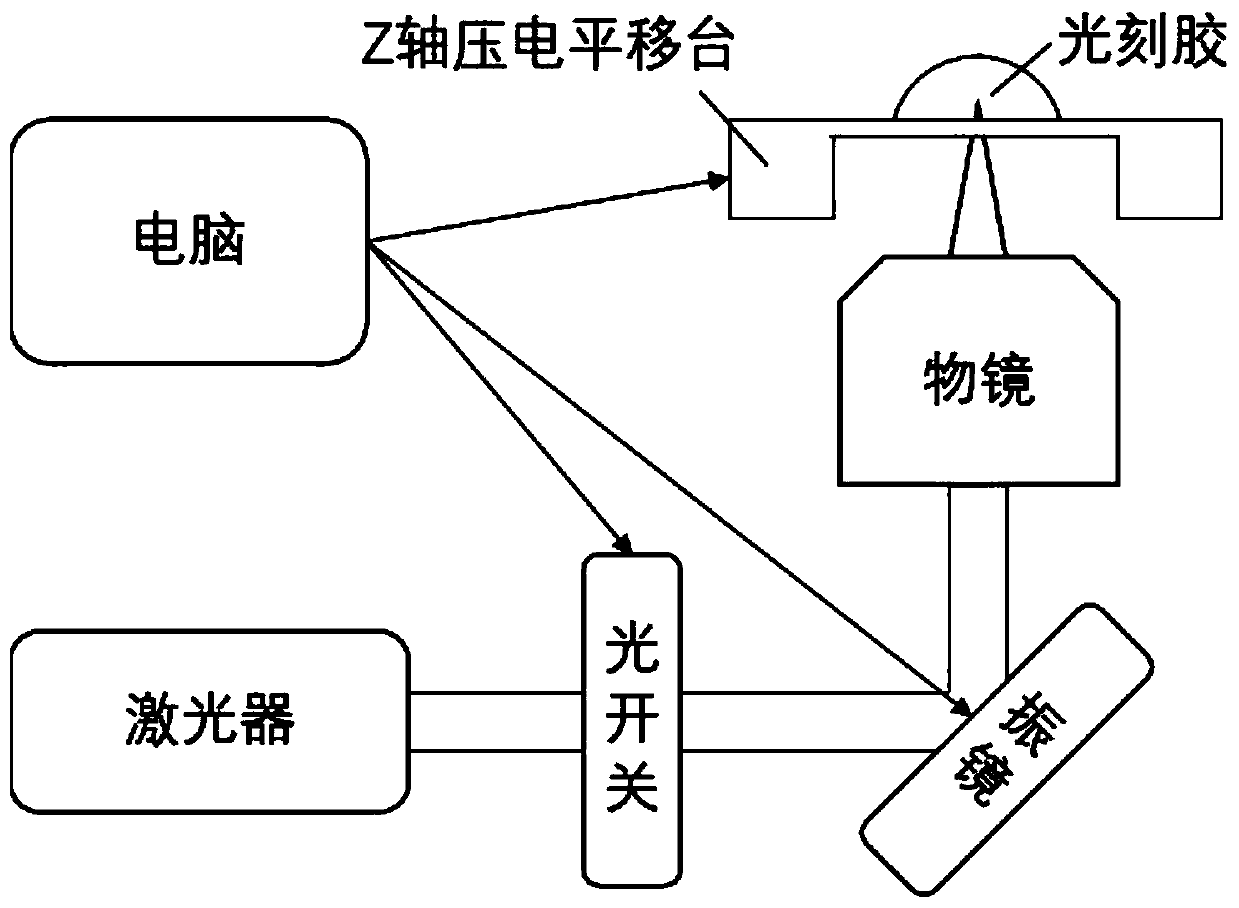

[0065] The structure of the two-photon printing system used in the present invention is as follows: figure 1 shown. The laser beam is emitted by a femtosecond laser, passes through an optical switch, and is tightly focused into the interior of the photoresist by a high-magnification objective lens. The optical switch is used to control the on-off of the optical path. According to the requirements, an optical power control system can be added before the optical switch to adjust the laser energy. The vibrating mirror is used to control the laser focus to perform two-dimensional scanning on the focal plane of the objective lens. The Z-axis piezoelectric translation stage is used to lift the sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com