Ink jet-printing curing device and operating method thereof

A curing device and ink technology, applied in printing devices, printing, etc., can solve problems such as inability to place and control spreading, inability to frequently switch on and off, and failure to function, so as to meet the needs of fully cured ink, ensure printing accuracy, and improve compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The gist of the present invention is to overcome the deficiencies of the prior art, and provide an inkjet printing curing device and its operation method, which combines pre-curing and final curing, first curing with LED to control its spreading, and only curing the surface layer of the spray film to ensure printing accuracy ; Then the high-pressure mercury lamp or metal halide lamp will fully cure it to ensure the performance of the ink.

[0018] The following will describe in detail with reference to the accompanying drawings in conjunction with the embodiments, so as to further explain the technical features and advantages of the present invention.

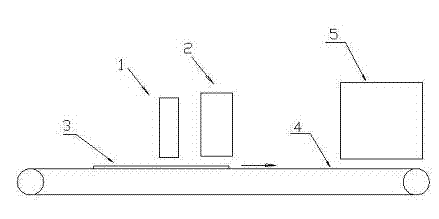

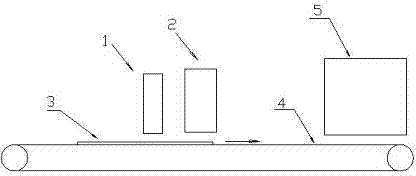

[0019] The structural principle of the present invention is as figure 1 As shown, an ink jet printing curing device includes a conveyor belt 4, a printing substrate 3 is placed above the conveyor belt 4, and a nozzle 1, a pre-curing device 2 and Final curing device 5. The pre-curing device 2 is an ultraviolet LED curin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com