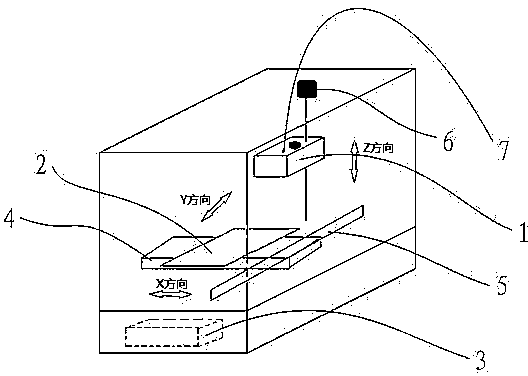

Three-dimensional (3D) rapid forming printing system and method

A printing system, 3D technology, applied in the field of 3D rapid prototyping printing system, can solve the problems of printing layer position error, printing error, 3D model size is not accurate enough, etc., achieve the effect of wide application, ensure printing accuracy, and avoid printing error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

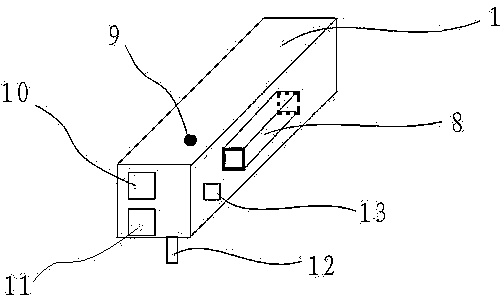

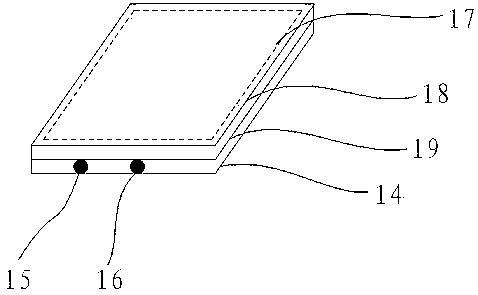

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: Take printing a cup as an example to illustrate a printing method of a 3D rapid prototyping printing system of the present invention, including the following steps:

[0047] Step 1: Designers use 3D modeling software (such as Auto CAD or 3D Max, etc.) to design the 3D model of the cup in the PC, adjust it to an appropriate size, output it as a file in STL format, and then import the 3D model in STL format into the control unit of the system.

[0048] Step 2: The control unit displays the 3D model of the cup, and slices the model layer by layer from bottom to top, then saves the slice data, and converts the control code into a control code and transmits it to the motion control unit 3 of the 3D rapid prototyping printing system .

[0049] Step 2.1: The display module displays the 3D model of the cup in the module by importing or opening, and can further modify the size and position of the 3D model, and can also adjust the viewing angle of the model.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com