Self-adaptive hierarchical algorithm for 3D (three-dimensional) printing

A technology of three-dimensional printing and layered algorithm, applied in the direction of additive processing, etc., can solve the problems of molding accuracy and molding efficiency, and achieve the effect of shortening molding time, ensuring printing accuracy, and improving molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

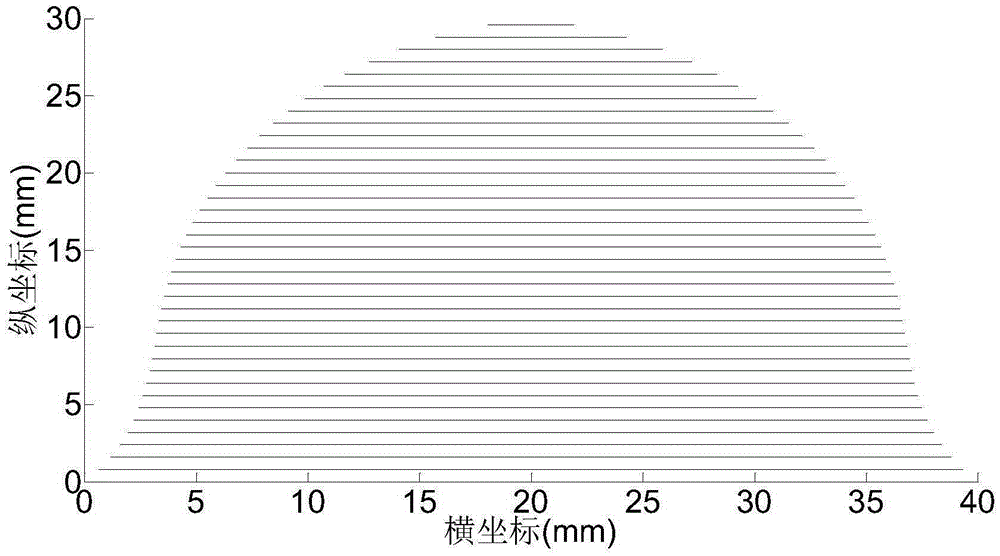

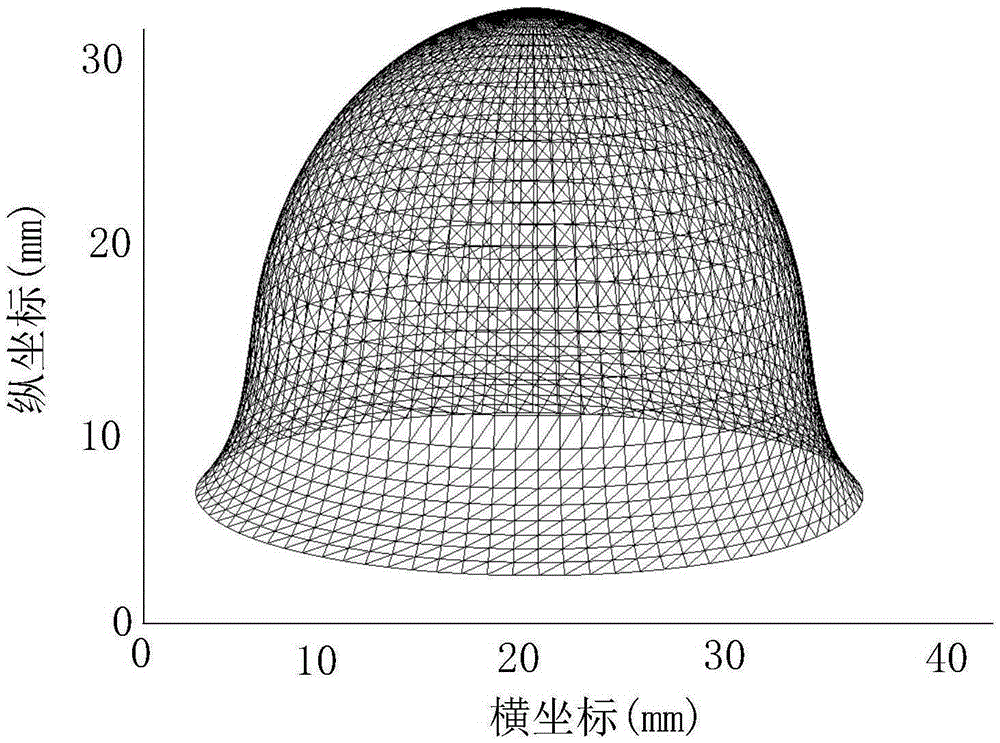

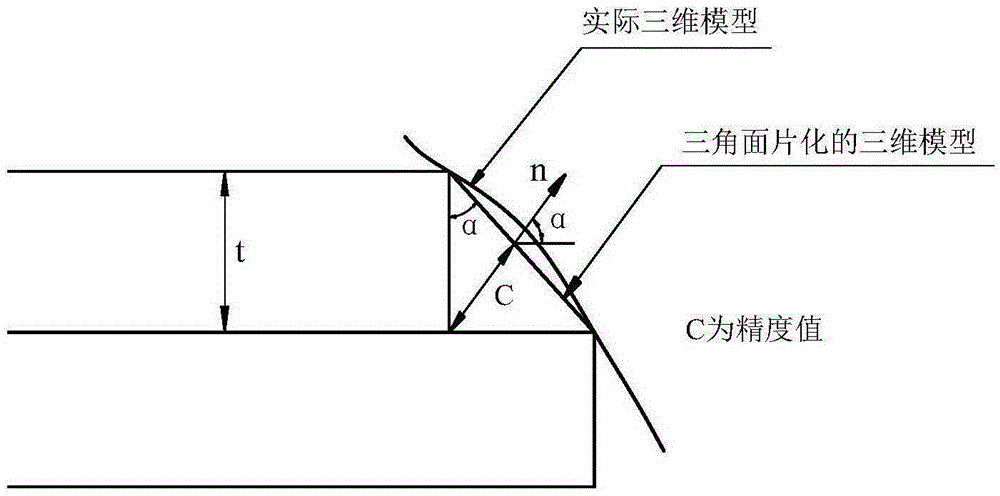

[0021] See figure 2 , the 3D model processed by the current 3D printing layered program is in STL format. The 3D model in STL format is made into triangular faces, that is, many triangular faces are used to form the curved shape of the physical model. Therefore, the 3D model in STL format is the right An approximation of the real thing. The STL file of the 3D model contains the coordinate values of the three points of each triangle and the normal vector of the triangle.

[0022] In order to implement adaptive layering, the curvature of each part of the model needs to be calculated first. Then automatically adopt the corresponding layer thickness value according to the size of the curvature.

[0023] The specific method is:

[0024] a) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com