Method for producing a lithium ion battery and lithium ion battery

A lithium-ion battery pack and battery pack technology, applied in battery electrodes, lithium storage batteries, secondary battery charging/discharging, etc., can solve the problems of electrode local short circuit, explosion, battery heating, etc., and achieve enhanced voltage reduction and improvement. The effect of diffusion resistance and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

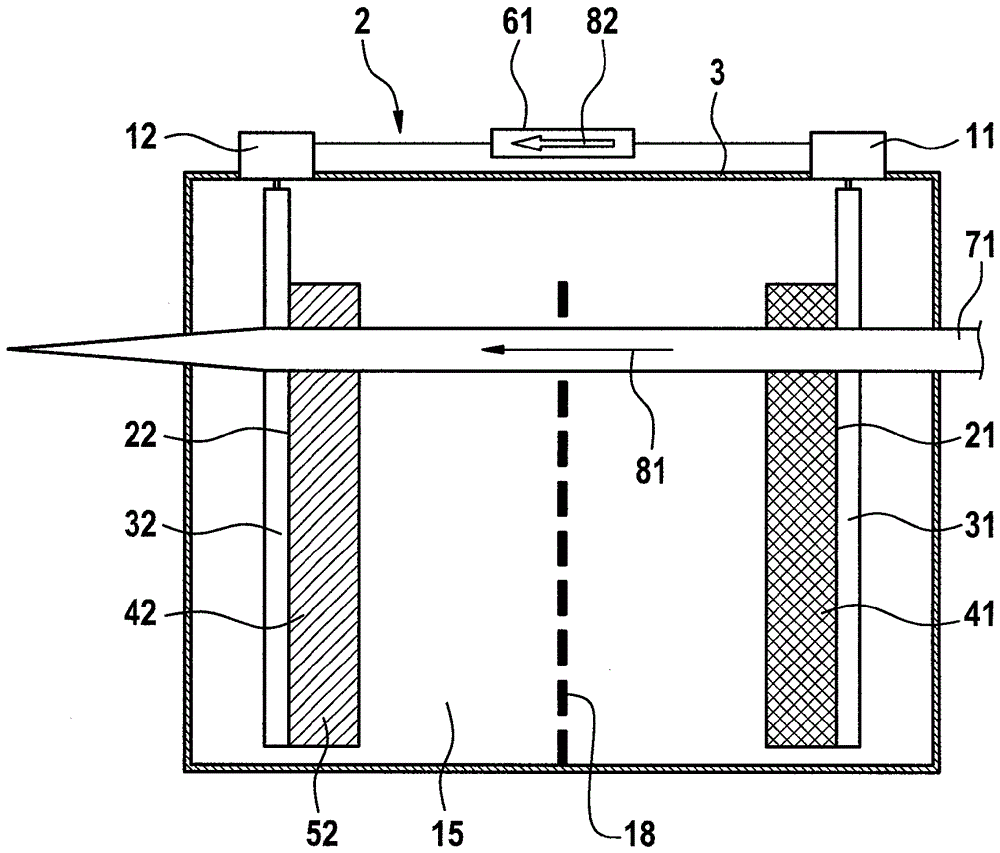

[0156] Make two Li-ion battery packs with the following characteristic values:

[0157] Positive electrode:

[0158] Active material: LiNi 0.8 co 0.15 al 0.05 o 2 (NCA)

[0159] Binder: about 3% by weight, based on the total amount of active material

[0160] Conductive material: carbon black, about 3%, based on the total amount of active material

[0161] Surface coverage: about 20 mg / cm 2

[0162] Negative electrode:

[0163] Active Material: Graphite

[0164] Binder: about 3% by weight, based on the total amount of active material

[0165] Surface coverage: about 15 mg / cm 2

[0166] Diaphragm:

[0167] Thickness: approx. 20 μm with ceramic coating

[0168] Pretreatment and Formation:

[0169] Precharged to approximately 10% state of charge (SOC)

[0170] into:

[0171] 2 cycles (charge and discharge) at 0.2 C, voltage limit 2.5 to 4.35 V

[0172] 1 cycle, at 1 C, voltage limit 2.5 to 4.35 V.

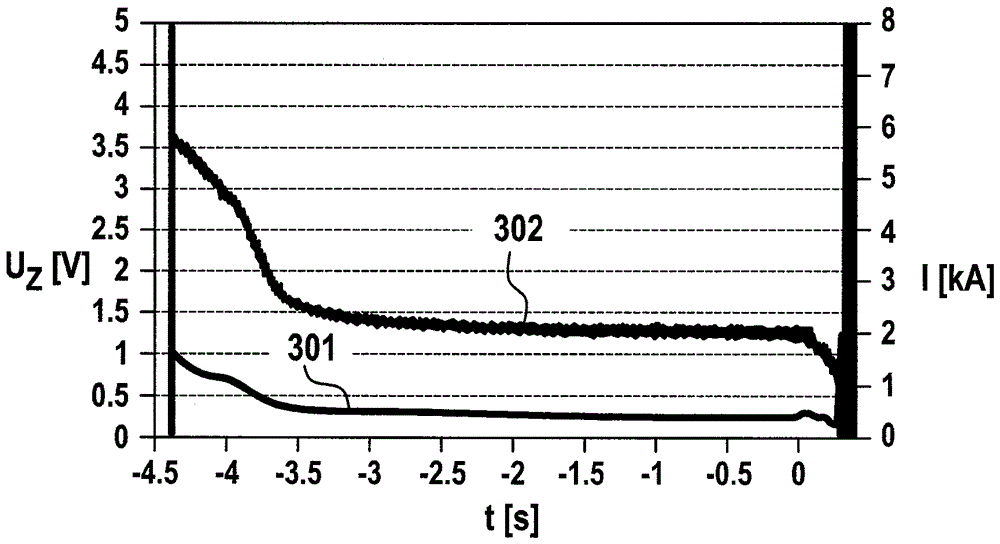

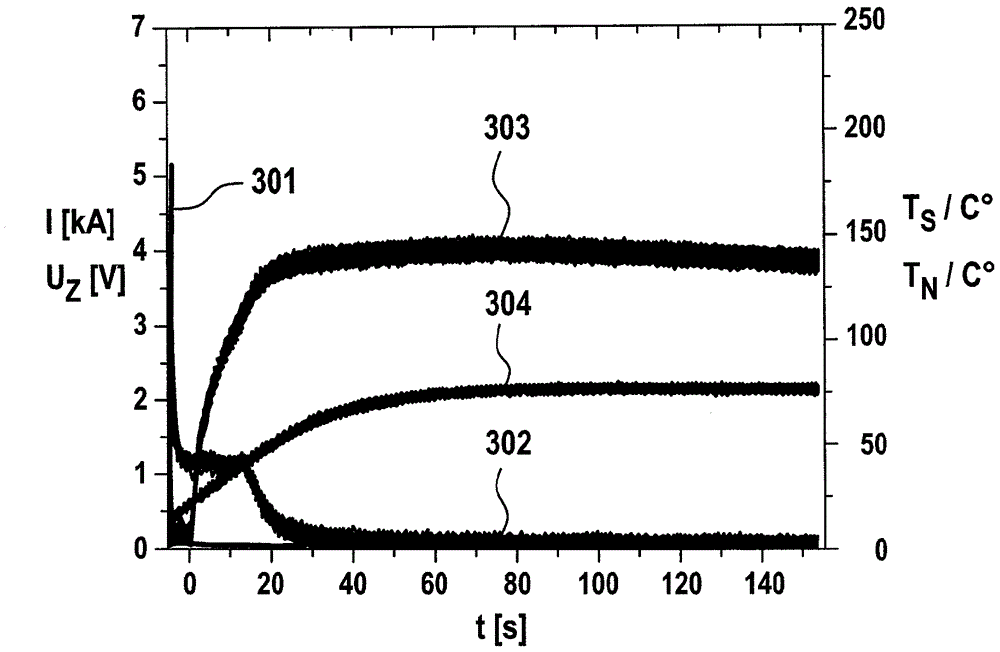

[0173] One of these cells was used as a control cell. Among t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com