Production process of biomass carbon-based briquetted coal for replacing fossil fuel

A biomass carbon source and fossil fuel technology, applied in the direction of fuel, solid fuel, biofuel, etc., can solve the problems of low boiler steam pressure and steam production, can not meet the needs of industrial production, can not meet the requirements of industrial molding, etc., to achieve Reduce the burning speed, have significant environmental protection benefits, and promote the effect of internal diffusion and circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

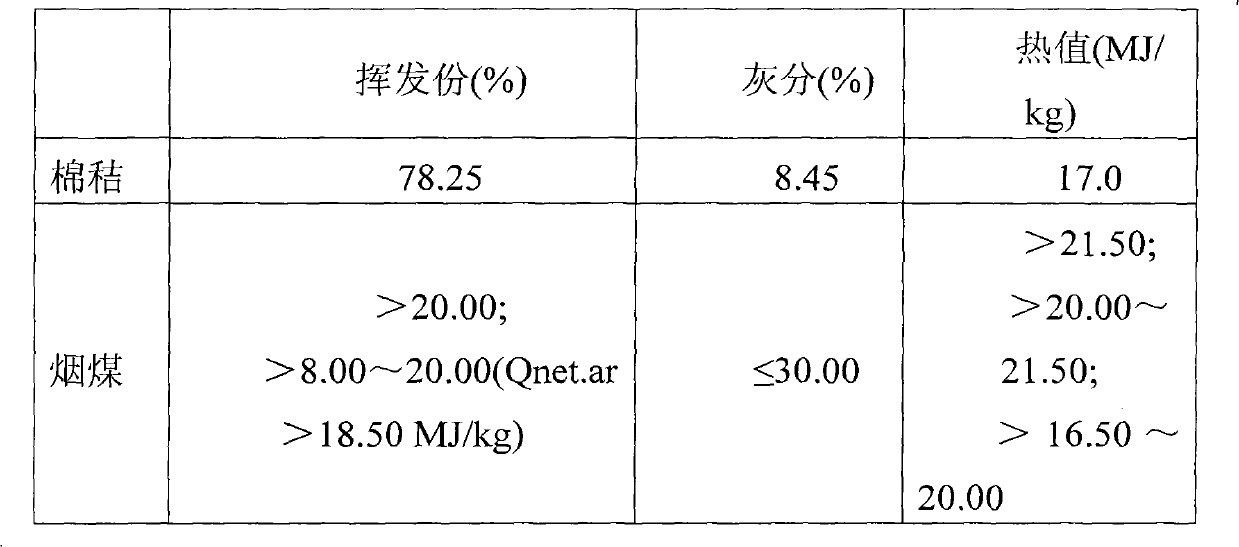

[0037] In the above-mentioned steps, taking cotton stalks as an example, the present invention is further described:

[0038] 1. Crush 100kg of cotton stalks into pieces of 2-6mm, dry until the water weight content is 4%, add 2g of potassium permanganate oxidant, 20g of vermiculite expansion agent and 400g of calcium lignosulfonate binder, and carry out Stir well to make it even. The chemical composition of the vermiculite used in the present invention: SiO2 37-42%, Al2O3 10-13%, MgO 14-23%, Fe2O3: 5-18%, CaO 0.5-0.8%.

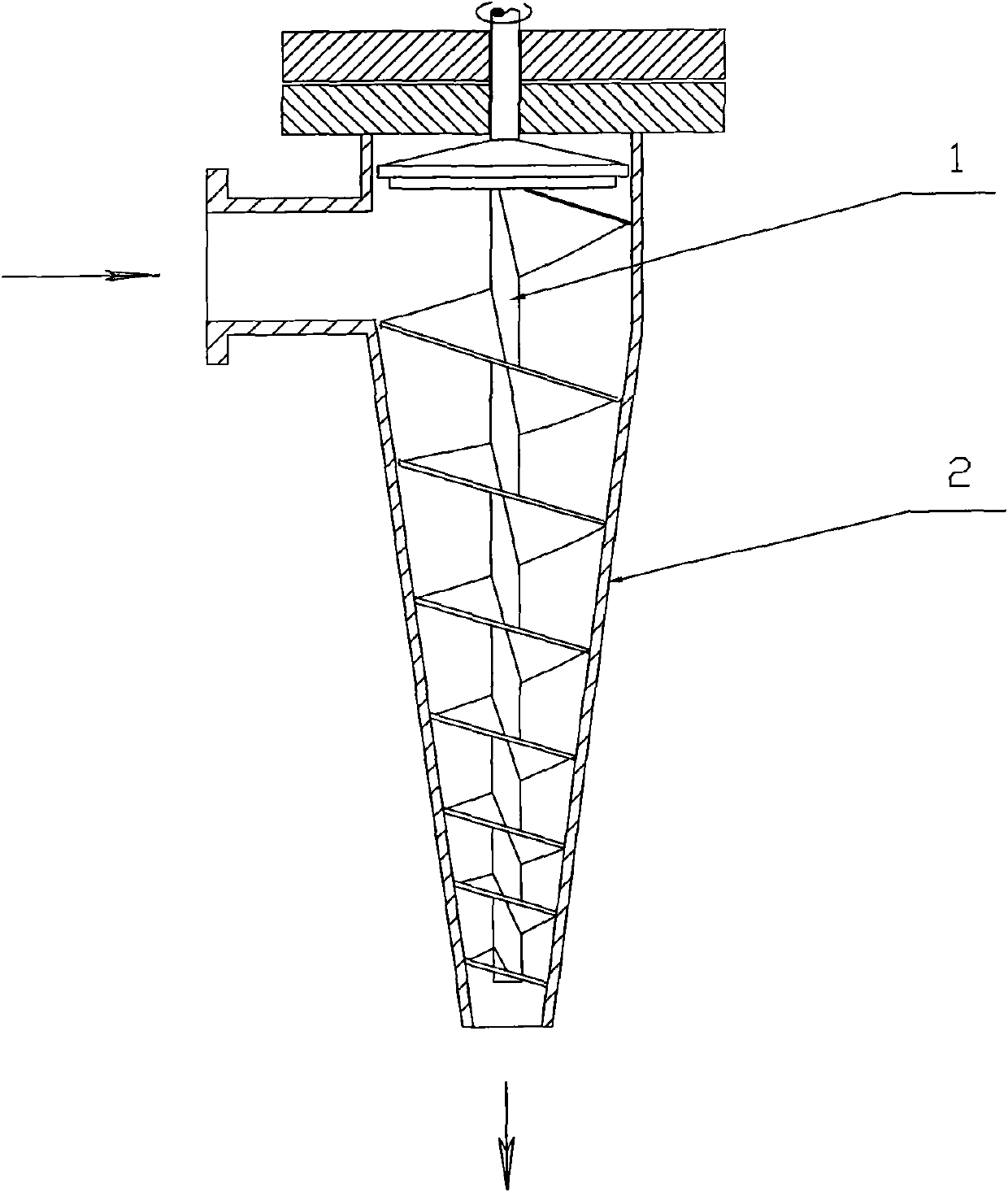

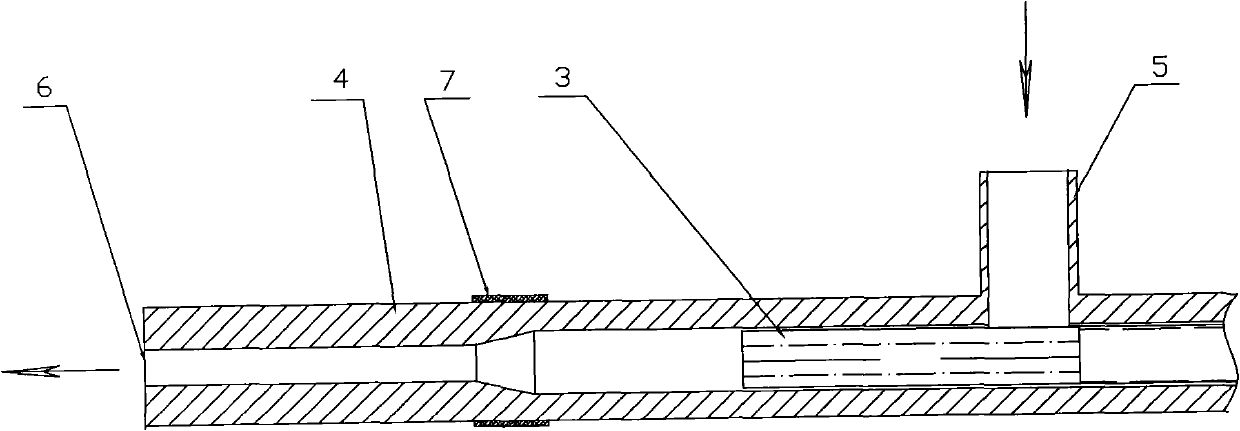

[0039] 2. The first-level pre-compression process is: the material in step 1 enters the pre-compression cylinder from the feed port of the cone screw compressor through the screw conveyor, and is squeezed when the cone screw rod pushes the material forward. The material of step 1 to the material whose compression ratio (volume) is 4:1. At this stage, the lower pressure is transferred to the biomass particles, so that the original loosely packed solid particl...

Embodiment 2

[0047] In the above-mentioned steps, take sawdust (Chinese fir) as an example, the present invention will be further described:

[0048] 1. Dry 100kg of sawdust (Chinese fir) to a moisture content of 6%, add 2g of potassium permanganate oxidant, 20g of vermiculite expansion agent and 100g of calcium lignosulfonate binder, and fully stir to make it even . The practical vermiculite chemical composition of the present invention: SiO2 37~42%, Al2O3 10~13%, MgO 14~23%, Fe2O35~18%, CaO 0.5~0.8%.

[0049] The preparation method is the same as in Example 1.

[0050] Comparison of biomass carbon source briquette coal produced with wood chips (fir) as the main raw material and GB / T 18342-2009 "Technical Conditions for Coal Used in Chain Grate Boilers":

[0051]

Embodiment 3

[0053] In the above-mentioned steps, take the peanut shell as an example, the present invention is further described:

[0054] Peanut shells are crushed into 2-6mm fragments, dried until the water weight content is 6%, 2g of potassium permanganate oxidizing agent, 20g of vermiculite expansion agent and 400g of calcium lignosulfonate binder are added, and fully stirred, Make it even. The practical vermiculite chemical composition of the present invention: SiO2 37~42%, Al2O3 10~13%, MgO 14~23%, Fe2O35~18%, CaO 0.5~0.8%.

[0055] The preparation method is the same as in Example 1.

[0056] Comparison of biomass carbon source briquettes produced with peanut shells as the main raw material and GB / T 18342-2009 "Technical Conditions for Coal Used in Chain Grate Boilers":

[0057]

[0058] The raw material sources of the following examples: rice straw (husk) and peanut shells are all industrial and agricultural production residues in various places. Its industrial analysis compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com