Multifunctional supercritical fluid processor for materials

A supercritical fluid and multi-functional technology, applied in the direction of pressure vessels used in chemical processes, bulk chemical production, etc., to achieve the effect of expanding the application range, realizing real-time adjustment, and expanding functional diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a multifunctional supercritical fluid processing machine for materials. The applicable materials processed can be textile fiber materials and products thereof, and various synthetic or natural polymer organic materials, or various inorganic materials. It can also be various composite materials, and it can also be materials such as food, feed, and crop by-products.

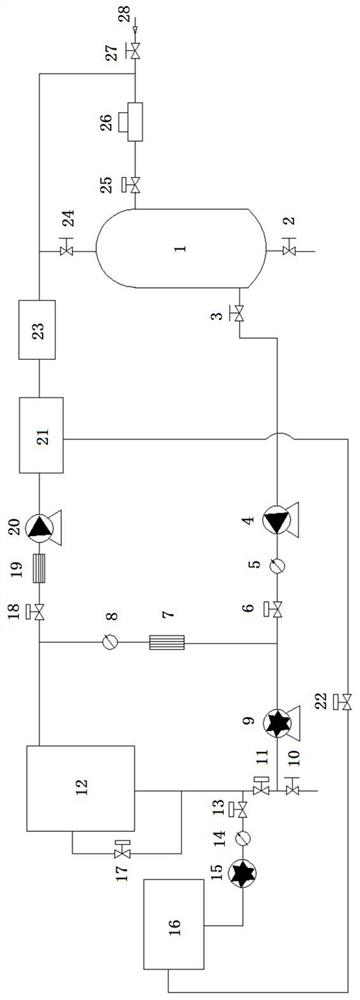

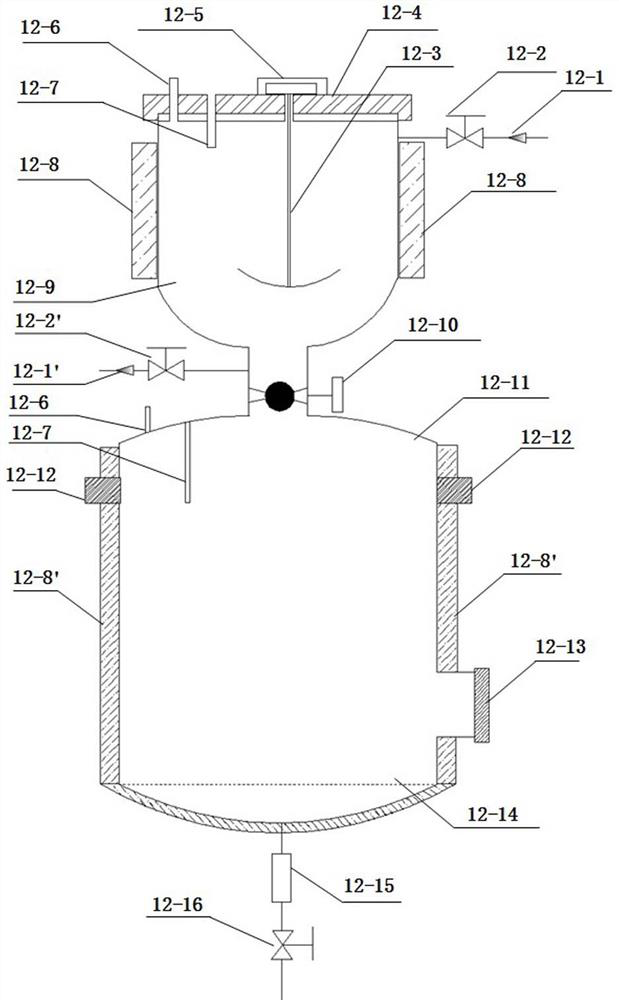

[0024] See attached figure 1, which is a schematic diagram of the system structure of the multifunctional supercritical fluid processing machine for materials provided in this embodiment; it includes a high-temperature and high-pressure fluid expansion processing system, a carbon dioxide medium pressurization system, an auxiliary medium pressurization system, a circulation treatment system, Separation and recovery system and auxiliary medium separation and recovery system. The specific structure is as follows:

[0025] The carbon dioxide medium pressurization system consists of CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com