Efficient treatment device for solid waste lead slag of storage battery

A processing device and storage battery technology, which is applied to the improvement of process efficiency, smoke and dust removal, cleaning methods and utensils, etc., can solve the problems of automatic proportioning, inconvenient manual cleaning, etc., and achieve uniform and high-efficiency processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

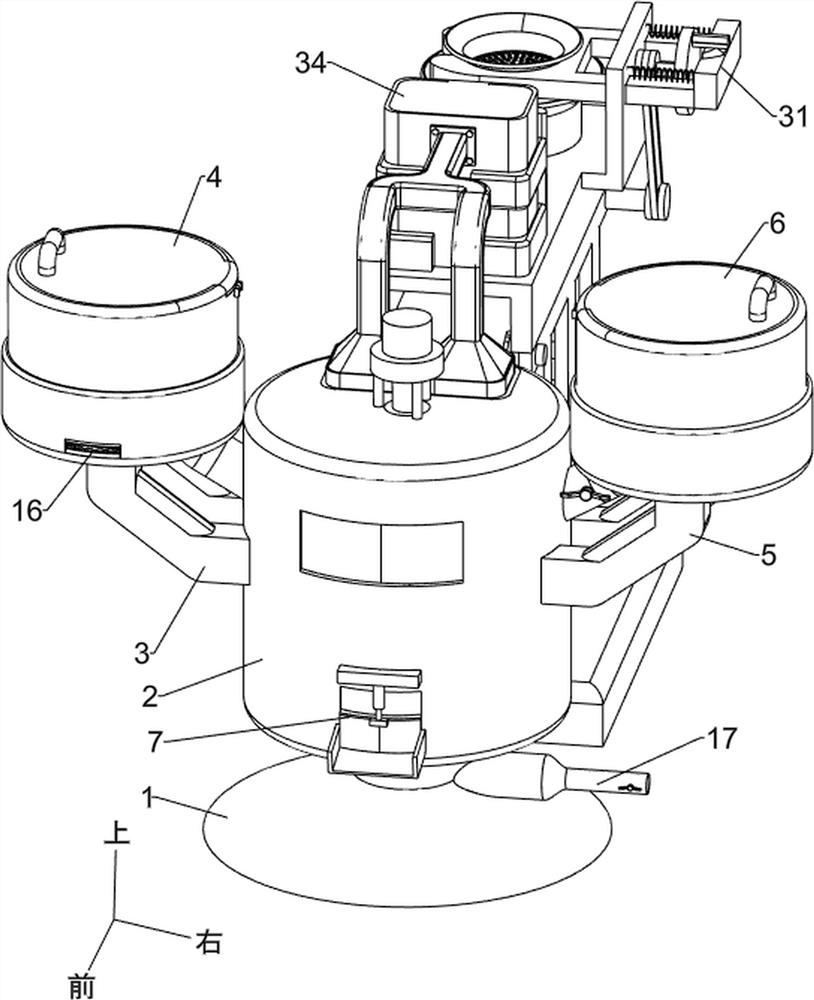

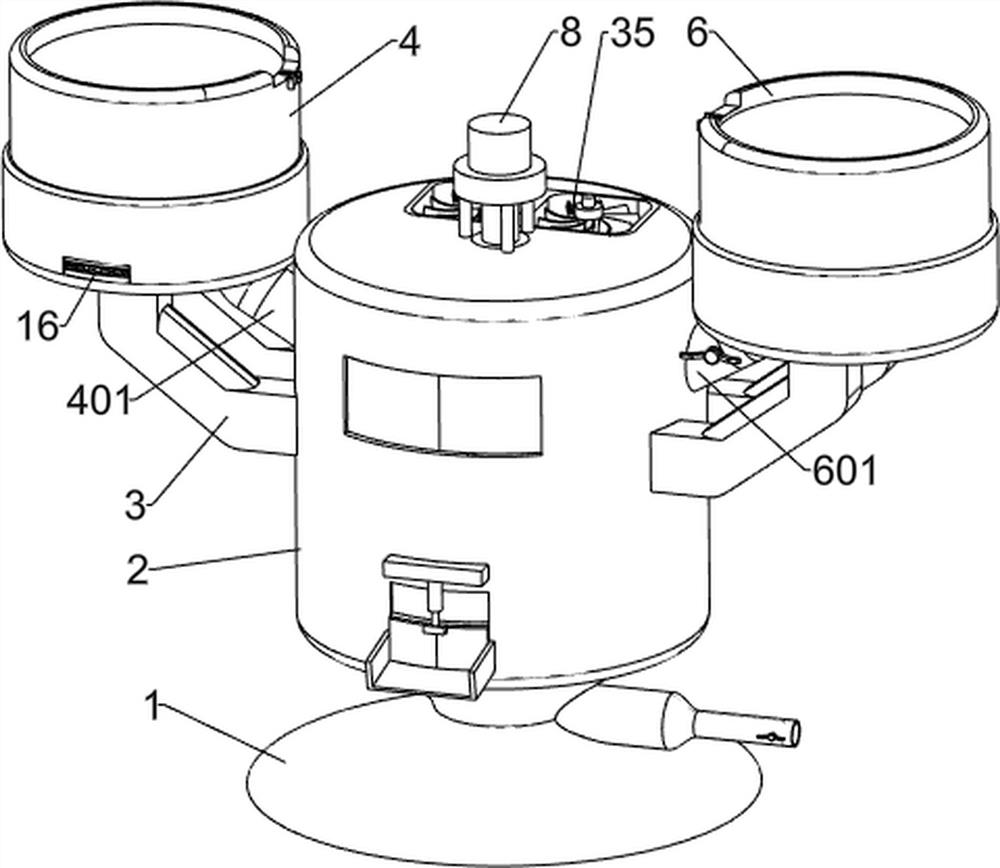

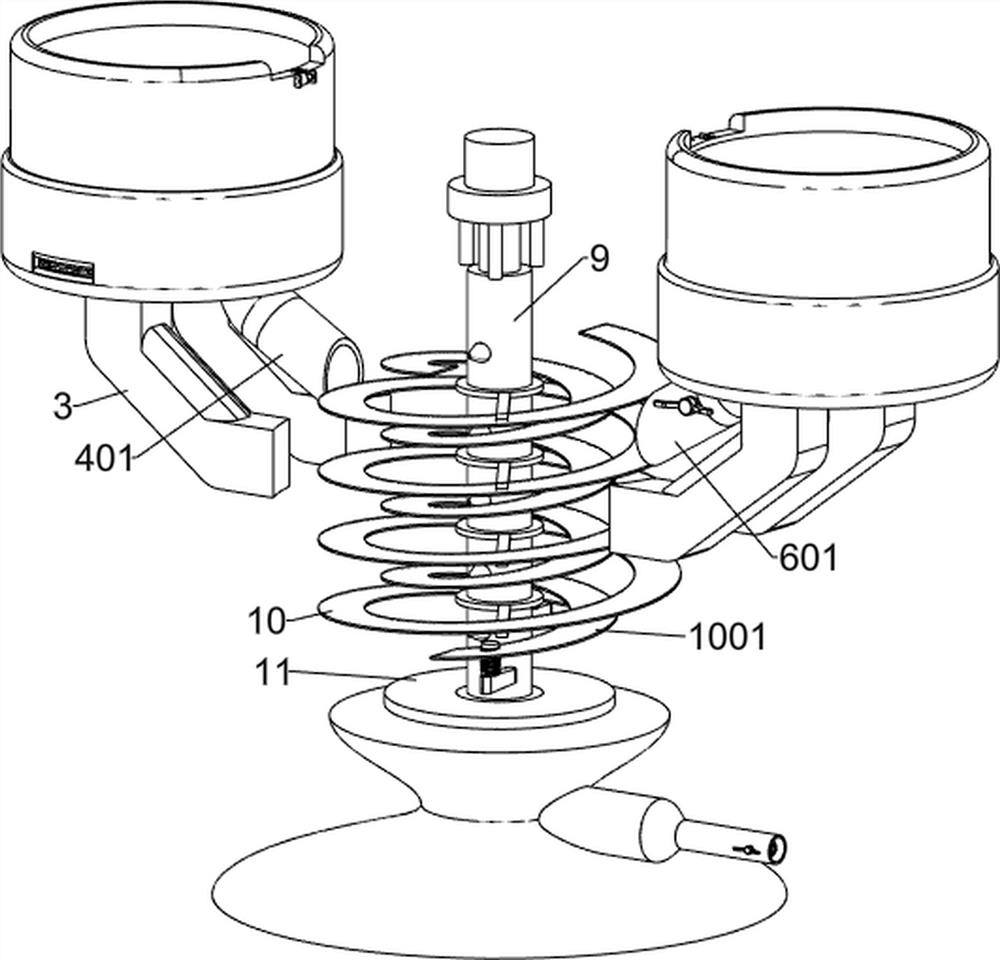

[0030] A high-efficiency treatment device for battery solid waste lead slag, such as Figure 1-Figure 3 As shown, it includes a chassis 1, a mixing barrel 2, a first support 3, a first barrel 4, a material control mechanism, a first delivery pipe 401, a second support 5, a second barrel 6, a second delivery pipe 601, and a flow guide The valve 7, the stirring motor 8, the rotating shaft 9, the first stirring wheel 10, the second stirring wheel 1001 and the bearing seat 11, the mixing tank 2 is fixedly connected to the chassis 1, and the first bracket 3 is fixedly connected to the left side of the mixing tank 2, The first bucket 4 is installed on the first bracket 3, and the first bucket 4 is used to place the coke powder. The first bucket 4 is connected with a first conveying pipe 401, and the other end of the first conveying pipe 401 is connected with the mixing barrel 2. The first The barrel 4 is provided with a material control mechanism, and the material control mechanism ...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 4 with Figure 5 As shown, the material control mechanism includes a first transmission wheel 12, a feeding tray 13, a second transmission wheel 14, a first belt 15 and a rotating disk 16, and the first barrel 4 is rotatably connected with a feeding tray 13, and the feeding tray 13 It is disc-shaped and provided with four circular through holes of different sizes. The first transmission wheel 12 is fixedly connected to the feeding tray 13, and the second transmission wheel 14 is rotatably connected to the first bucket 4. The second transmission wheel 14 The first belt 15 is wound around the first transmission wheel 12, and the second transmission wheel 14 is fixedly connected with a rotating disk 16. After rotating the rotating disk 16 by hand, the blanking tray 13 will also rotate together.

[0034] When an appropriate amount of coke powder and adhesive were introduced into the mixing tank 2 through the first delivery pipe 40...

Embodiment 3

[0036] On the basis of Example 2, such as Figure 6 As shown, it also includes a water inlet pipe 17 and a water spray head 18. The chassis 1 is fixedly connected with a water inlet pipe 17, and a water control valve is installed on the water inlet pipe 17. The water inlet pipe 17 is used to communicate with the external water pipes. 9 interiors are connected, and the rotating shaft 9 is provided with a plurality of sprinklers 18 evenly arranged, and the water that the external water pipe passes into the water inlet pipe 17 inside can be sprayed by the sprinklers 18.

[0037] When the mixing bucket 2 needs to be cleaned after using the mixing bucket 2, the water outlet of the external water pipe is communicated with the water inlet pipe 17 on the mixing bucket 2, then the external water pipe switch is turned on, and then the water control valve installed on the water inlet pipe 17 is opened, and the water flow It will be sprayed from the water spray head 18 on the rotating sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com