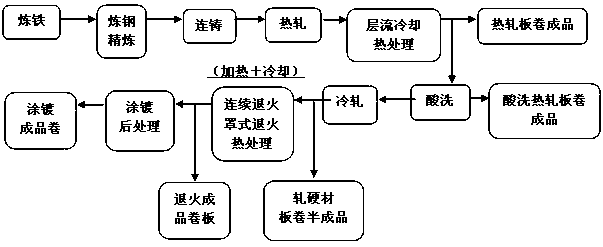

Compact type fine-grain high-strength plate strip steel production line flexible manufacturing method

A flexible manufacturing and production line technology, applied in the direction of manufacturing tools, furnace types, and improving energy efficiency. Grain size grade, effect to achieve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

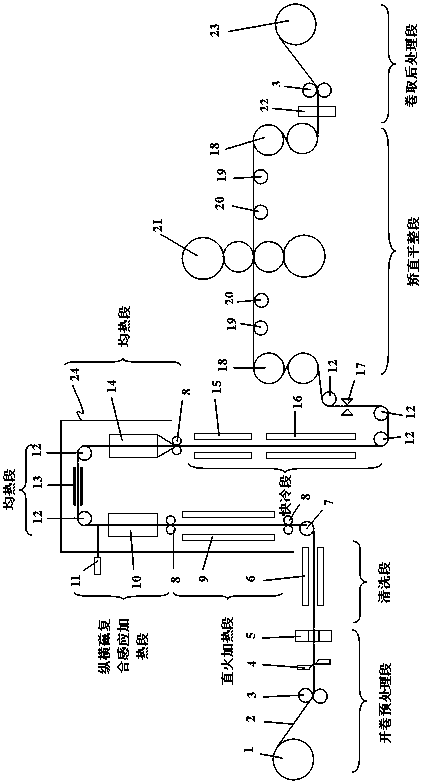

[0046] see figure 2 , a flexible manufacturing method for a compact fine-grained high-strength plate and strip steel production line, including: an uncoiling pretreatment section, a cleaning section, a direct fire heating section, a vertical and horizontal magnetic composite induction heating section, a rapid soaking section, a rapid cooling section, and a tension leveling section. Straightening section and post-processing coiling section.

[0047] The uncoiling pretreatment section includes an uncoiler 1, a pinch roll 2, a head cutting machine 4 and a welding machine 5, and pretreats incoming sheet and strip coils so that the production line can run continuously and stably; in this embodiment, the sheet and strip mainly Refers to strip steel 2.

[0048] The cleaning equipment 6 of the cleaning section includes hot water washing, alkali washing or necessary pickling equipment, which is arranged before the furnace heating section of the whole production line to degrease and d...

specific Embodiment 1

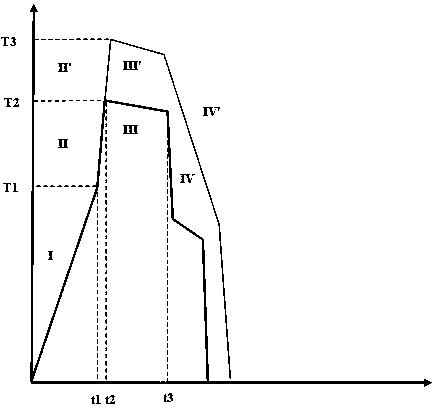

[0062] Specific embodiment 1: For a common carbon cold-rolled steel rolled hard coil variety, such as SPCC, DC steel, etc., select the direct fire heating section to 600 ° C, add 600-700 ° C longitudinal magnetic induction heating, and add 700-850 ° C transverse magnetic induction heating; Or direct fire heating section to 600 ℃, add 600-850 ℃ transverse magnetic induction heating. Soaking <20s, jet and mist cooling can obtain higher strength, grain refinement up to 50%, and deep drawing performance r value of the material increased by 50%.

specific Embodiment 2

[0063] Specific embodiment 2: A stainless steel cold-rolled hard coil type, such as 304, select the direct fire section to 700 ° C, and add 700-1100 ° C transverse magnetic induction heating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com